Rope-driven wrist module based on three-degree-of-freedom series-parallel hybrid mechanism and use method of rope-driven wrist module

A hybrid mechanism and degree of freedom technology, applied in the directions of manipulators, program-controlled manipulators, joints, etc., to achieve the effect of simple and compact structure, solving the problem of rope coupling, and good bionics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0038] see Figure 1-10 , the present invention provides a technical solution:

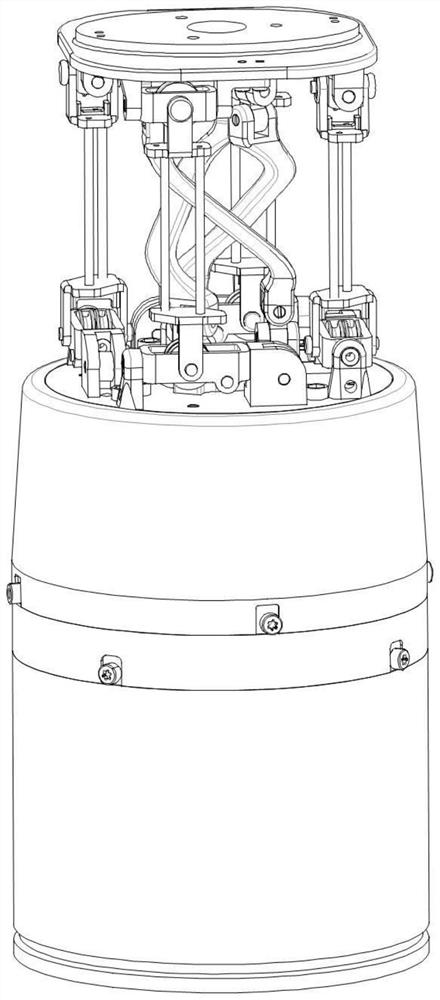

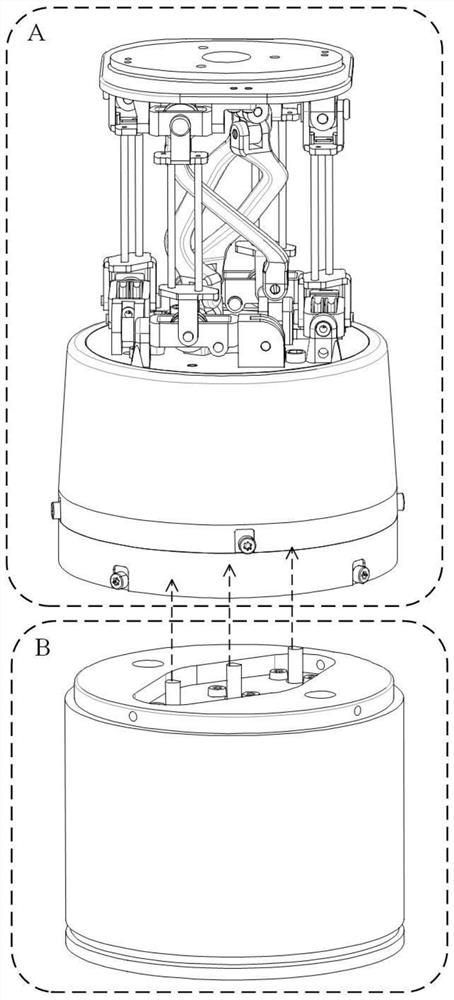

[0039] The present invention proposes a rope-driven wrist module based on a three-degree-of-freedom serial-parallel hybrid mechanism and its application method, such as figure 1 , 2 As shown, the wrist module is composed of a three-degree-of-freedom series-parallel module A and a drive control integrated module B, which are fixed by screws on the side of the housing for easy connection and disassembly.

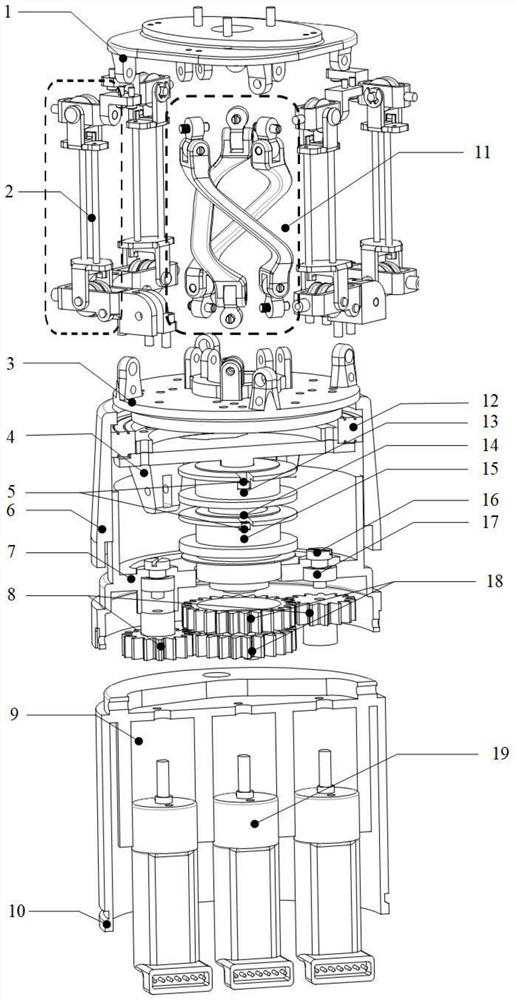

[0040] The three-degree-of-freedom series-parallel module A, such as image 3 As shown, the upper platform 1 of the parallel mechanism, the tension amplification mechanism 2, the lower platform 3 of the parallel mechanism, the rotating connection table 4, the rope fixing screw 5, the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com