Full-automatic destacking machine

A depalletizing machine, fully automatic technology, applied in the direction of conveyor, object stacking, object destacking, etc., can solve the problems of low efficiency and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

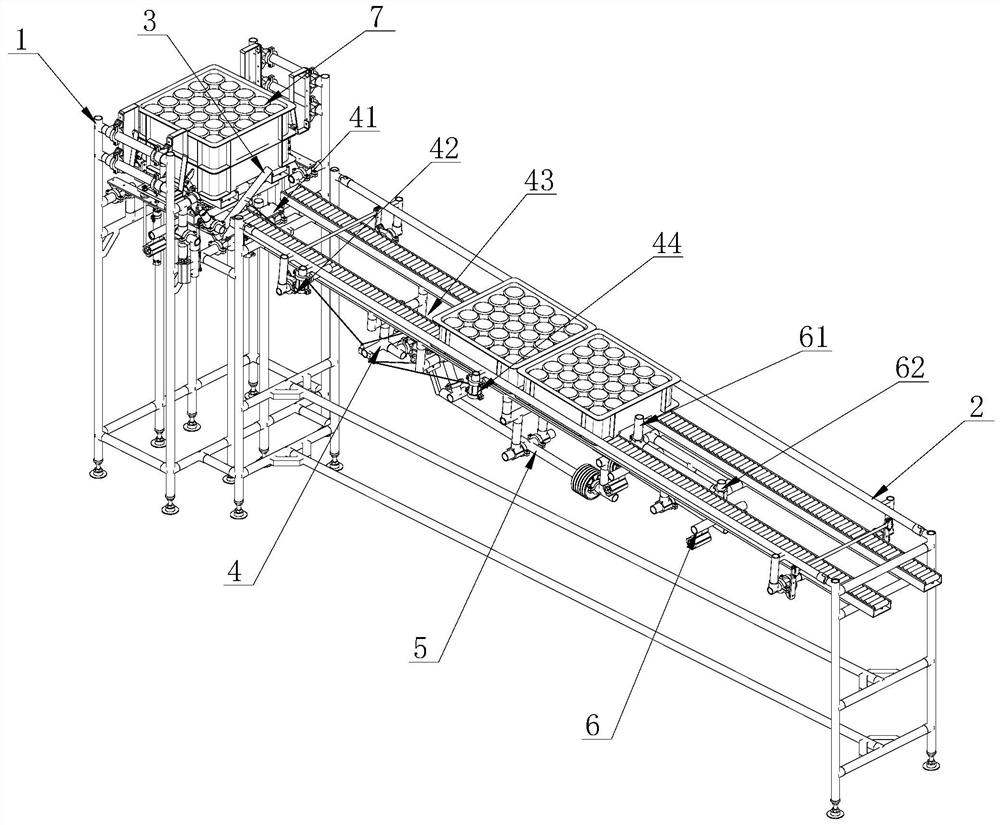

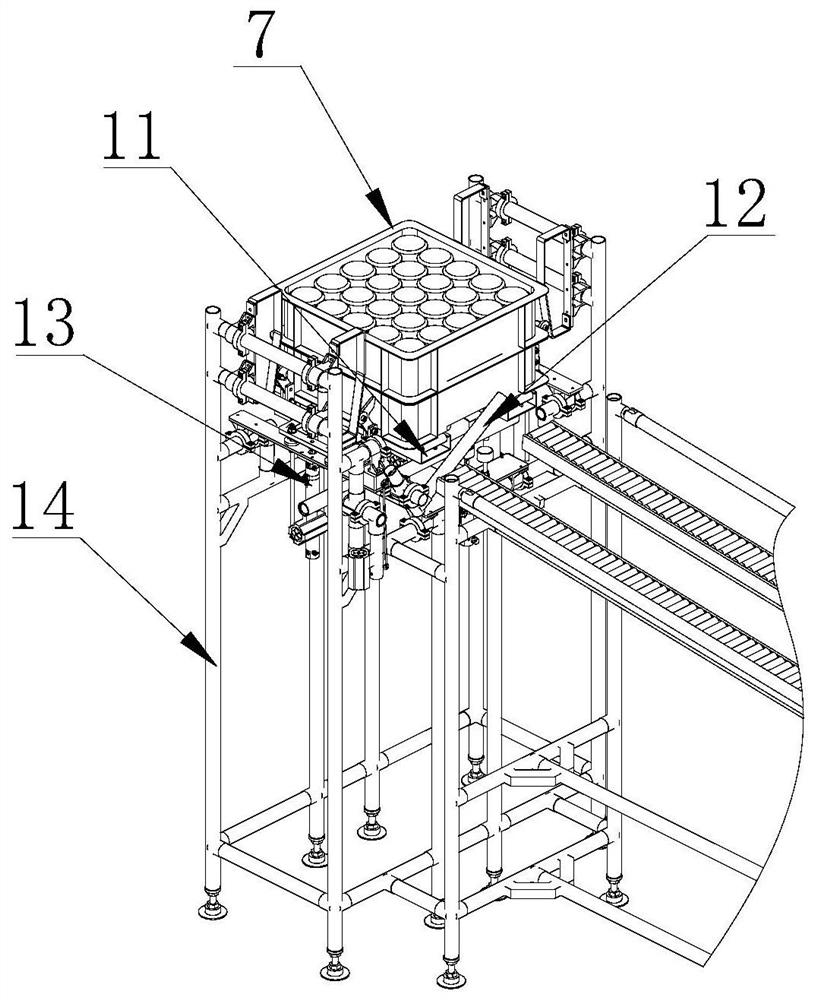

[0068] like Figure 1-19 A fully automatic depalletizer shown includes a depalletizing mechanism 1 and a conveying mechanism 2. The depalletizing mechanism 1 is used to introduce a single material box 7 onto the conveying mechanism 2, so that the material box 7 is inclined under its own gravity. The transportation is completed on the conveying mechanism 2, and the trigger mechanism 4, the linkage mechanism 5 and the limit mechanism 6 are arranged on the conveying mechanism 2 from back to front, and a swingable L Shaped gate tube 3, the gate is closed when the gate tube 3 swings to the top, and the gate is opened when it swings to the bottom;

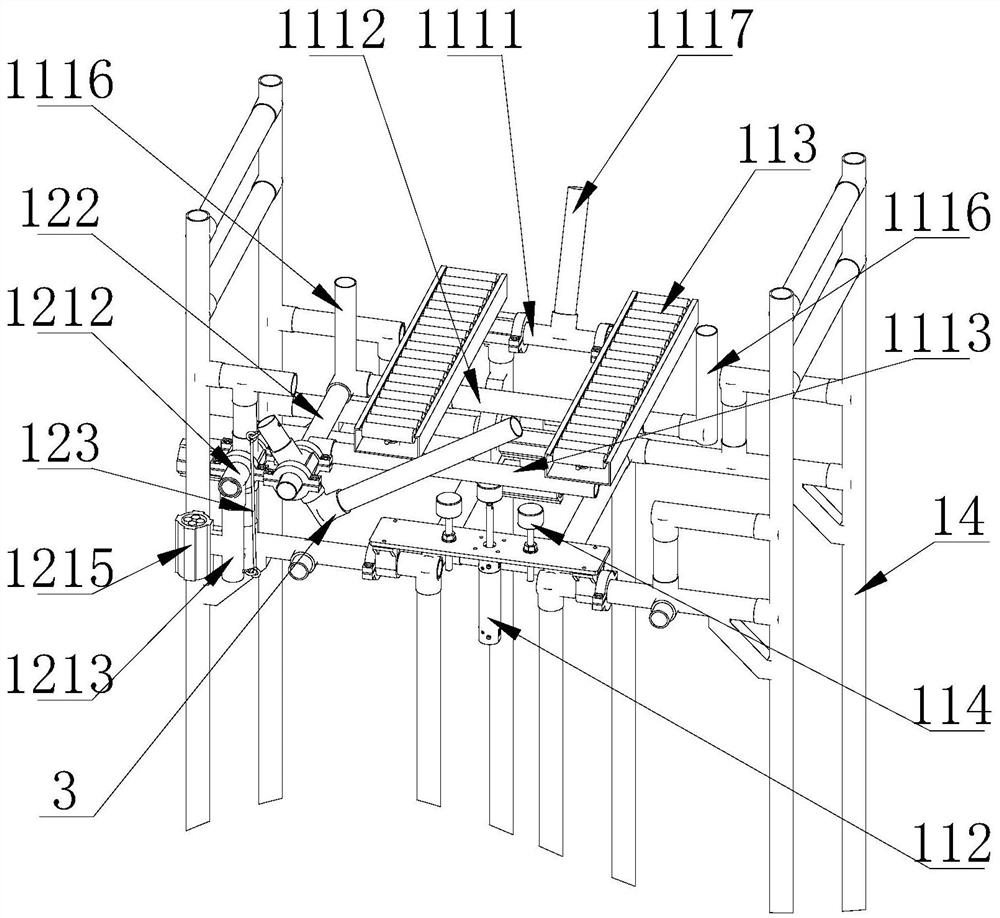

[0069] The depalletizing mechanism 1 includes a support assembly 11 installed on a support pipe frame 14, a barrier assembly 12 and a separation assembly 13, the support assembly 11 and the barrier assembly 12 cooperate with each other; the support assembly 11 is arranged in the middle of the support pipe frame 14, The barrier assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com