Main winch system of rotary drilling rig

A technology of rotary drilling rig and main winch, which is applied in the direction of rotary drilling rig, hoisting device, rotary drilling, etc., which can solve the problems of drill pipe loss and increase of system thermal load, so as to reduce thermal load and load rate , the effect of saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

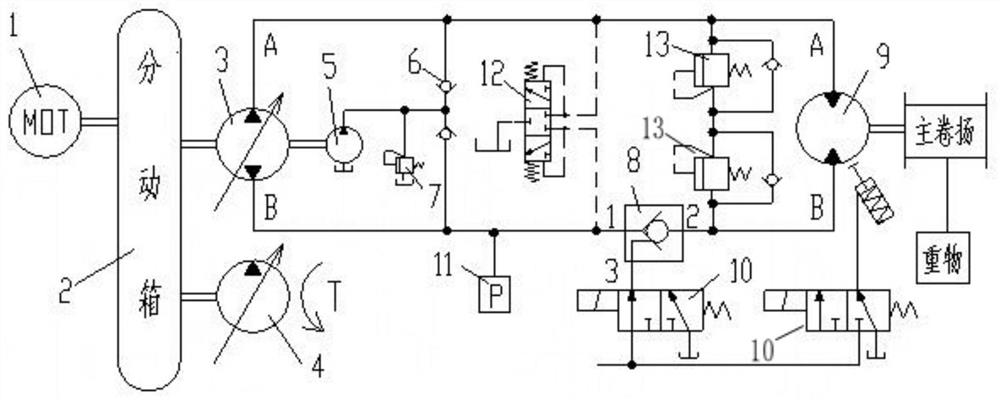

[0014] Such as figure 1 As shown, a main winch system of a rotary drilling rig includes an engine 1, a transfer case 2, a closed main pump 3, an open main pump 4, an oil charge pump 5, a one-way valve 6, an overflow valve I7, and an explosion-proof valve 8. Main winch motor 9, two solenoid valves 10, pressure sensor 11, flushing valve 12, overflow valve II13. The engine 1 is connected to the input end of the transfer case 2, and the output end of the transfer case 2 is respectively connected to the closed main pump 3 and the open main pump 4, and the open main pump 4 is used for other hydraulic systems. When the main hoist is performing a lifting action, the closed main pump 3 outputs power to the main hoist motor 9 . When the main winch is lowering, the pressure oil on the load side of the main winch motor reacts on the closed main...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap