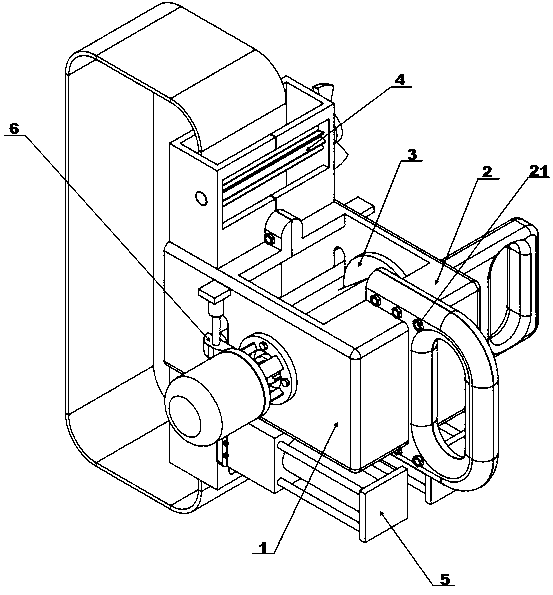

A portable aluminum ingot binding device

A portable, aluminum ingot technology, used in packaging, bundling materials, parts of bundling machinery, etc., can solve the problems of poor bundling effect of aluminum ingots, loss of corporate property, and inability to fix aluminum ingots, and improve the rationality of operation. and stability, improve the effect of convenient assembly and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

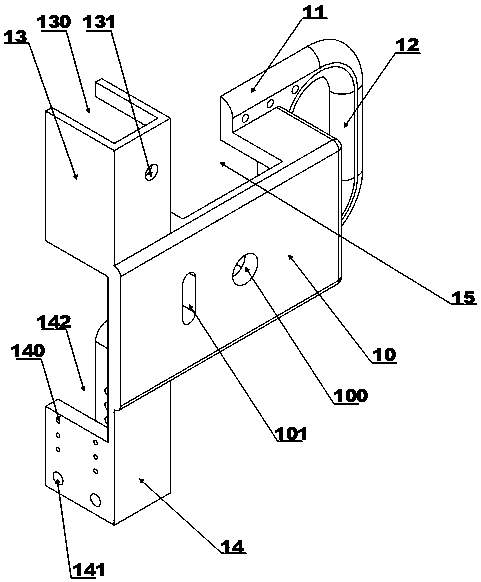

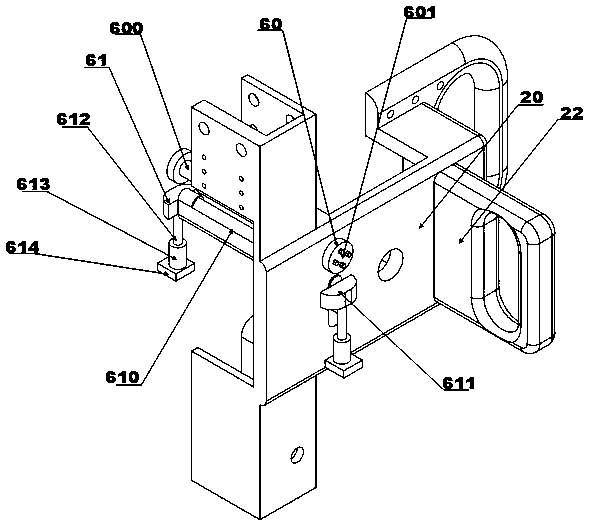

[0057] 1. Thread the winding wheel 33 wrapped with the steel strap 34 on the rotating rod 30, and thread the rotating rod 30 on the rod hole 100;

[0058] 2. Tighten the first outer collar 31, the first inner collar 32 and the second inner collar 35 respectively, so that one end of the rotating rod 30 is assembled on the driving rod 390;

[0059] 3. Start the motor 39, relax the strap 34, and be able to wrap the strap 34 around the bundled aluminum ingot once;

[0060] 4. After the strap 34 is wrapped around the aluminum ingot, the other end of the strap is inserted into the gap formed by the tightening wheel 40 and the tightening square hole 130, and the tightening wheel 40 is rotated so that one end of the strap 34 passes through the press hole Inside hole 142;

[0061] 5. Start the motor 39 in the reverse direction, so that the strap 34 will continue to be tightened until the motor 39 cannot rotate;

[0062] 6. Start the hole-pressing cylinder 51, so that the hole-pressing plate 53 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap