Pipeline anti-corrosion layer tiny damage point positioning method based on stationary wavelet transform

A technology of stable wavelet and positioning method, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., it can solve the problem of inability to extract tiny damage points, small damage point area of anti-corrosion layer, and inability to evaluate the integrity of pipeline anti-corrosion layer. Accuracy etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

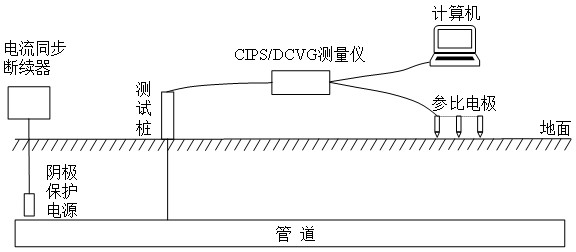

[0038] Please refer to figure 1 , the present invention provides a system for locating tiny damage points of pipeline anti-corrosion coatings based on stationary wavelet transform, comprising a current synchronous interrupter, a cathodic protection power supply, a test pile, a CIPS / DCVG detector, a data processing terminal and a copper sulfate reference electrode; The pipeline to be tested is connected to a current synchronous interrupter through a cathodic protection power supply; the test pile is connected to the pipeline to be tested; the CIPS / DCVG detector is connected to a test pile, a data processing terminal and a copper sulfate reference electrode respectively.

[0039] A method for locating tiny damage points of pipeline anti-corrosion coating based on stationary wavelet transform includes the following steps:

[0040] Step S1: Obtain power-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com