A construction method of a bridge-assembled expansion joint device

A construction method and technology of expansion joints, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as dust pollution, time-consuming and labor-intensive problems, and achieve the effects of avoiding environmental pollution, reducing construction steps, and enhancing connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

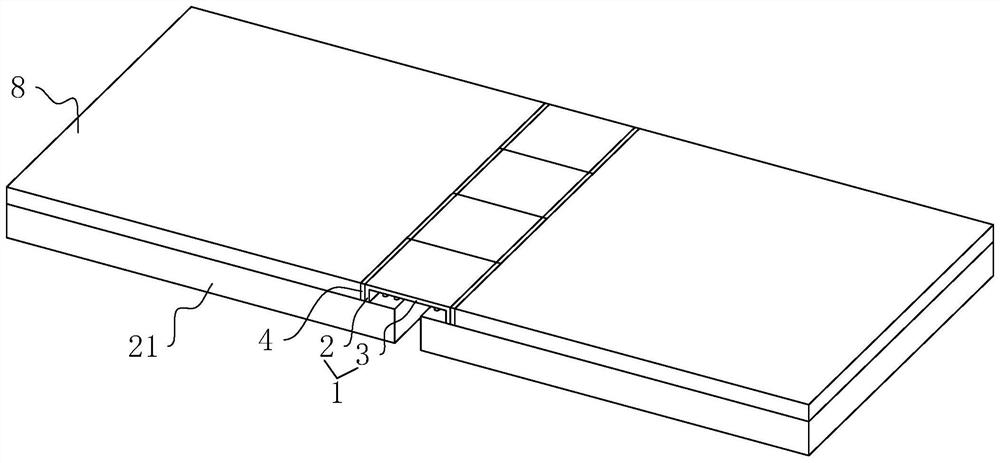

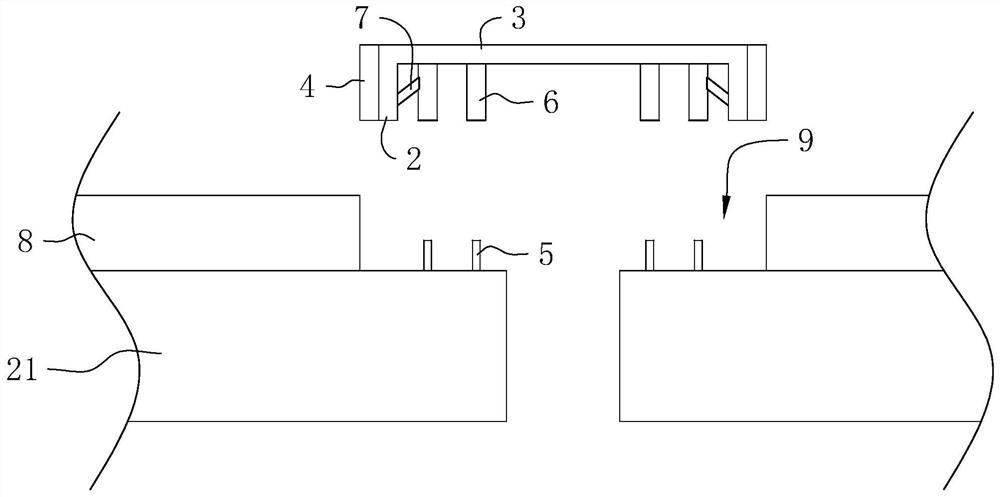

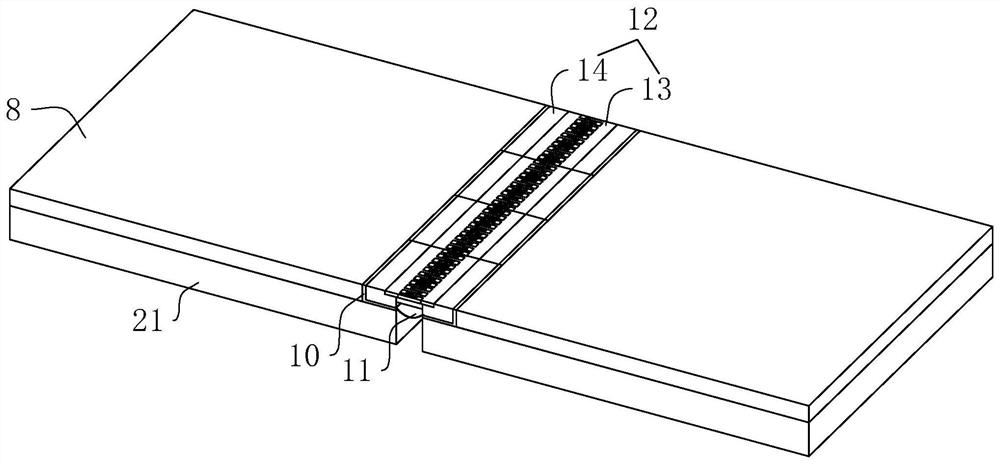

[0035] Attached to the following Figure 1-5 This application will be described in further detail.

[0036] The embodiment of the present application discloses a construction method of a bridge-assembled expansion joint device. refer to figure 1 and figure 2 , the construction method includes the following steps:

[0037] Step 1. Build a temporary support between the ends of two adjacent beams 21 used for building bridges that are close to each other. The temporary support includes a plurality of unit segments 1. The unit segment 1 includes a support plate 3 and is integrally formed on the support plate. 3. The two baffles 2 on the opposite two side walls, the length direction of the support plate 3 is arranged along the length direction of the bridge, the two ends of the support plate 3 respectively extend to one end of the two adjacent beam bodies 21, the baffle 2 is vertically arranged and the lower end abuts On the upper surface of the beam body 21, the height of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com