Environment-friendly dust-free coating stripping device

A peeling device, an environmentally friendly technology, used in construction, building maintenance, building construction, etc., can solve the problems of inconvenient use, poor paint peeling effect, large equipment, etc., achieve high operating effects, avoid clogging and wall sticking, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

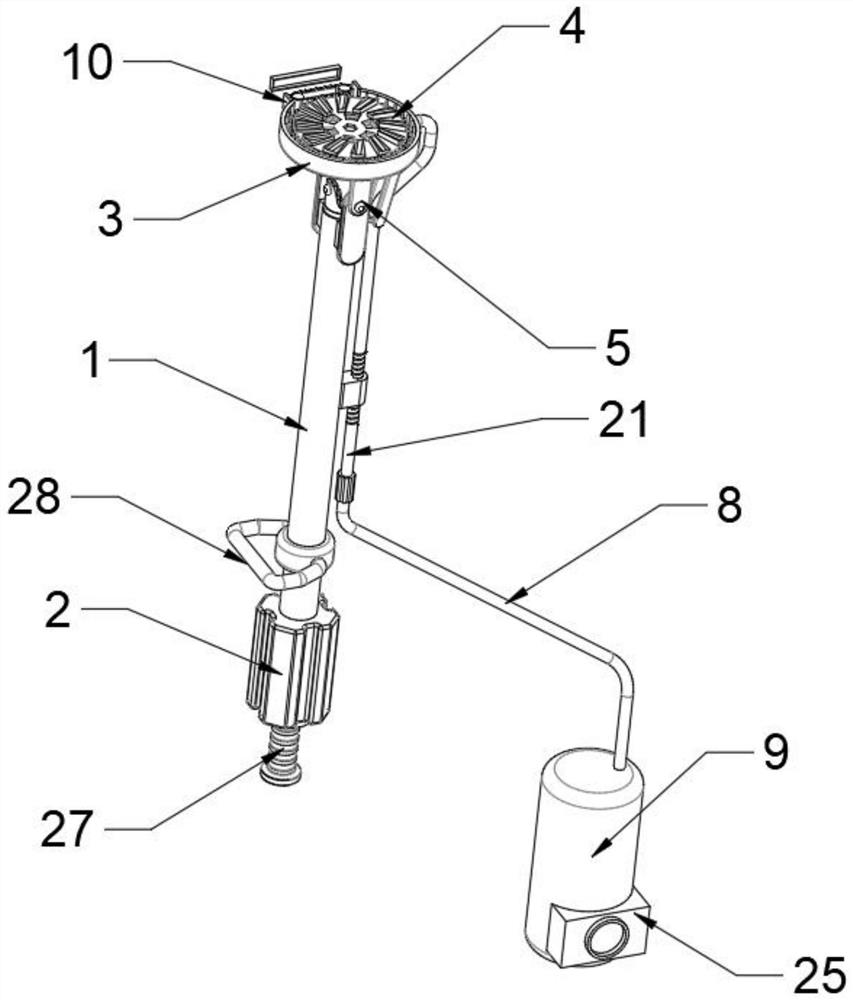

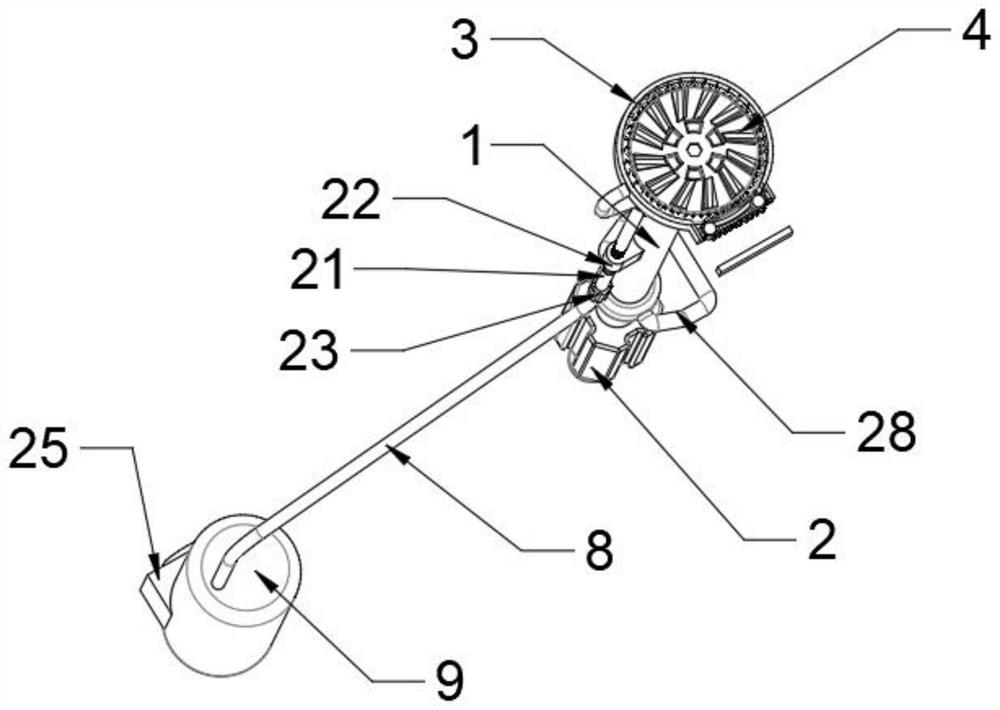

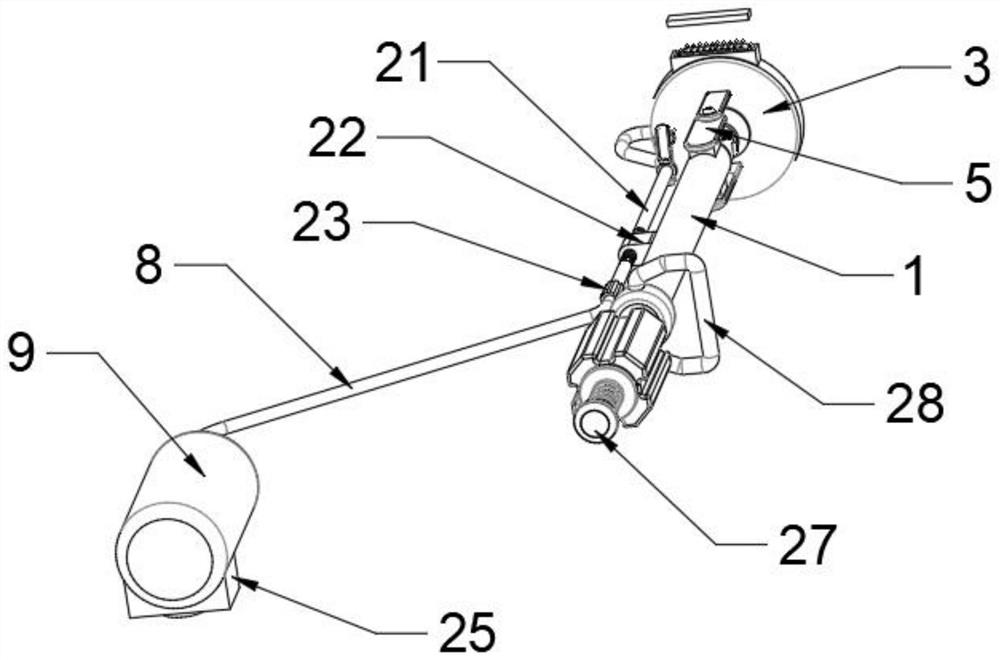

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0040] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

[0041] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6The shown environment-friendly paint dust-free stripping device includes a main rod 1, a drive motor 2 is fixedly arranged at the bottom of the main rod 1, a cover body 3 is provided on the side of the main rod 1 away from the drive motor 2, and a cover body 3 is provided inside the cover body 3. There is a disc cutter 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com