Compressor five-cavity air suction muffler and compressor

A compressor and muffler technology, applied in the field of compressors, can solve the problems of inability to take into account low-frequency and high-frequency noise, easy loose sealing, large matching gap, etc., to achieve good noise reduction and efficiency improvement, and take into account noise and performance. , Improve the effect of the anechoic frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

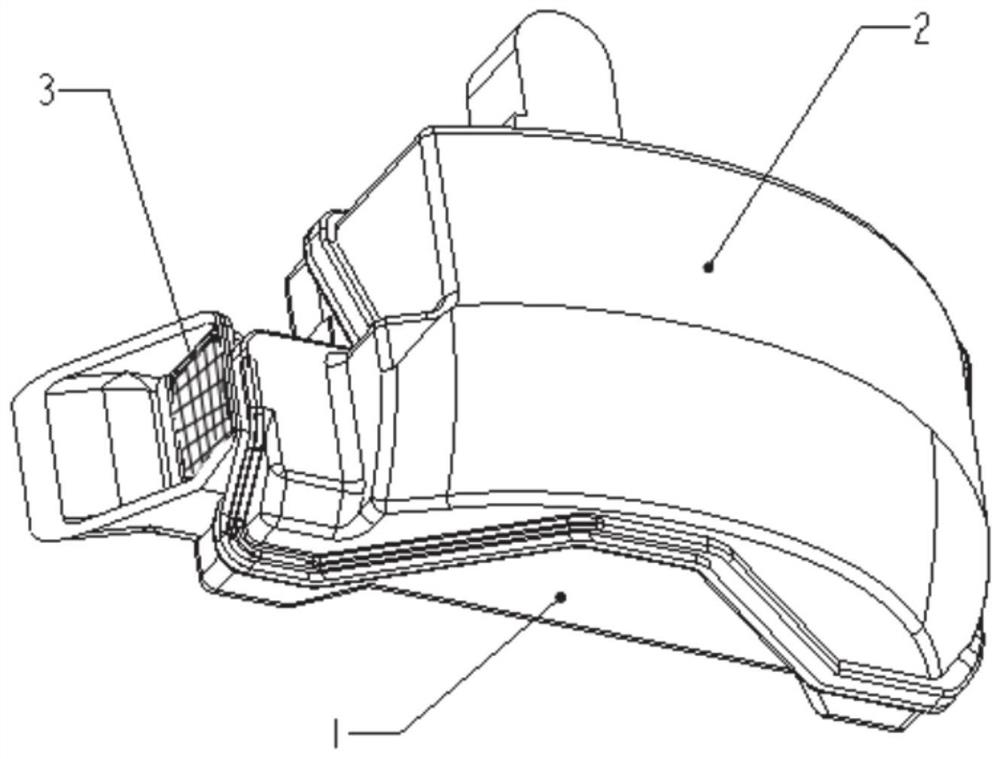

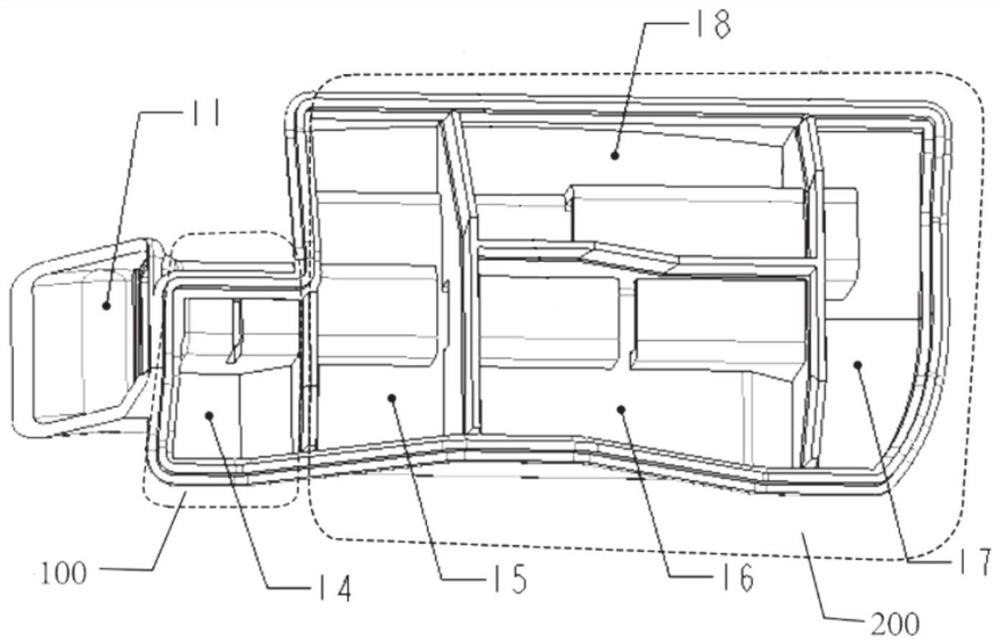

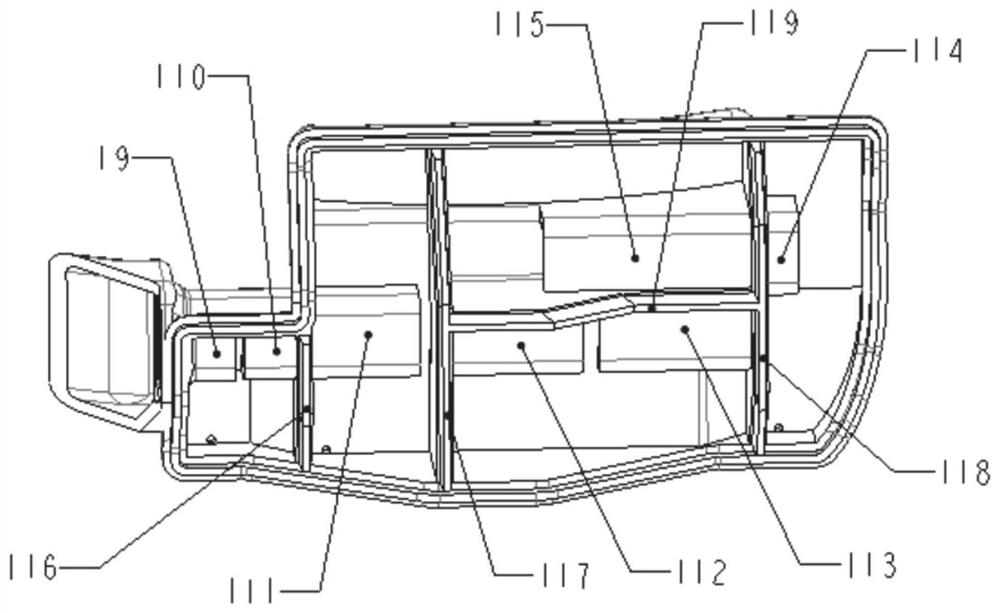

[0027] In a typical implementation of the present invention, this embodiment discloses a compressor five-chamber suction muffler, including a container and a filter screen 3, the container has an opening 11, and the filter screen 3 is installed at the opening 11 of the housing, The area of filter screen 3 is equal to the area of opening 11; There is a cavity inside the container, and a plurality of partitions are installed inside the container, and the cavity inside the container is divided into connected first cavity 14, second cavity by multiple partitions. The cavity 15 , the third cavity 16 , the fourth cavity 17 and the fifth cavity 18 , wherein the first cavity 14 communicates with the opening 11 of the container.

[0028] Further, the container in this embodiment includes a first shell 1 and a second shell 2, the edges of the first shell 1 and the second shell 2 are detachably connected, and the first shell 1 and the second shell 2 A plurality of baffles are provide...

Embodiment 2

[0045] A compressor, characterized by comprising the compressor five-chamber suction muffler according to any one of claims 1-9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com