Powdered ink filling cover

A technology for capping and toner filling, which is applied to instruments, equipment for electrical recording technology using charge patterns, optics, etc., can solve problems such as toner clogging, and achieve the effects of simple structure, strong practicability, and easy reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

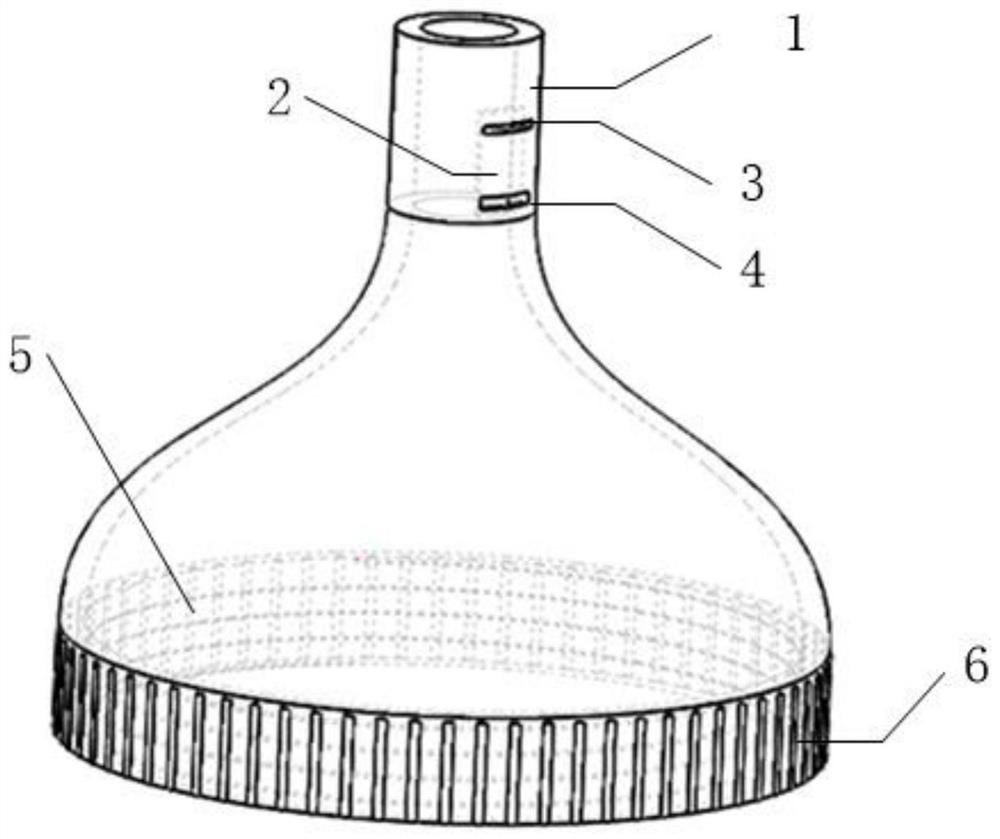

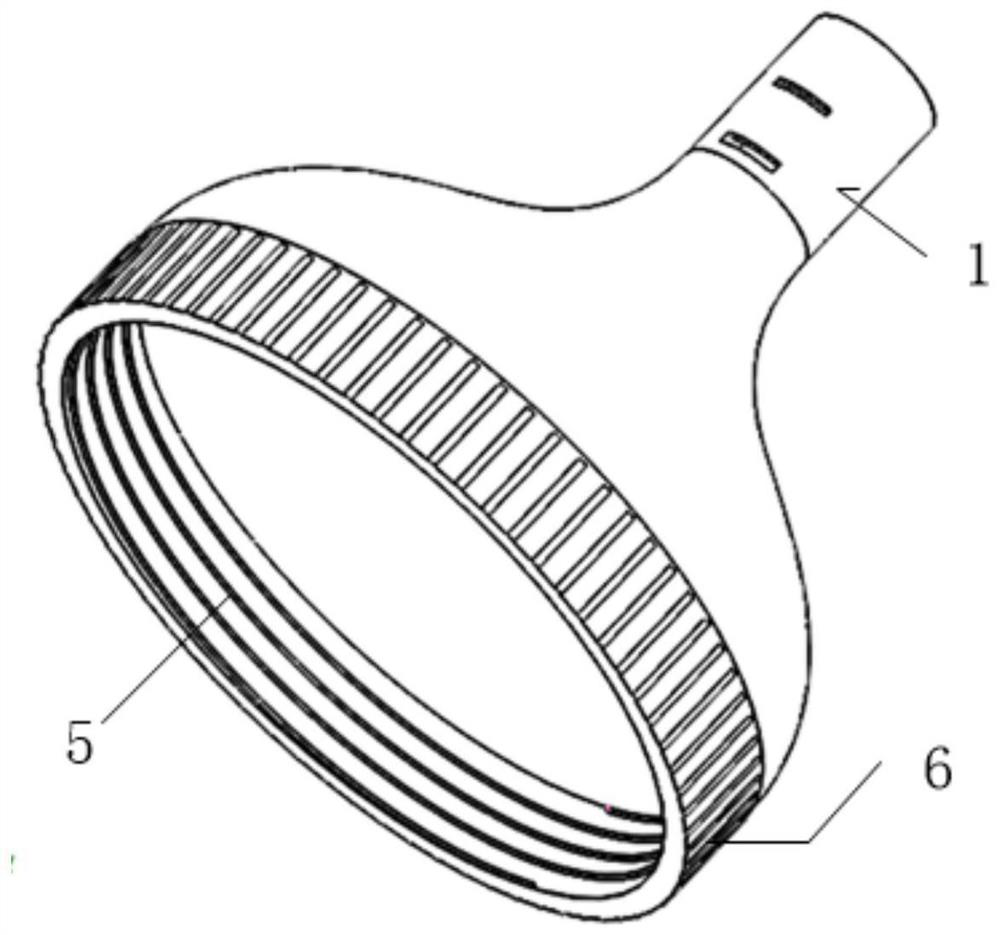

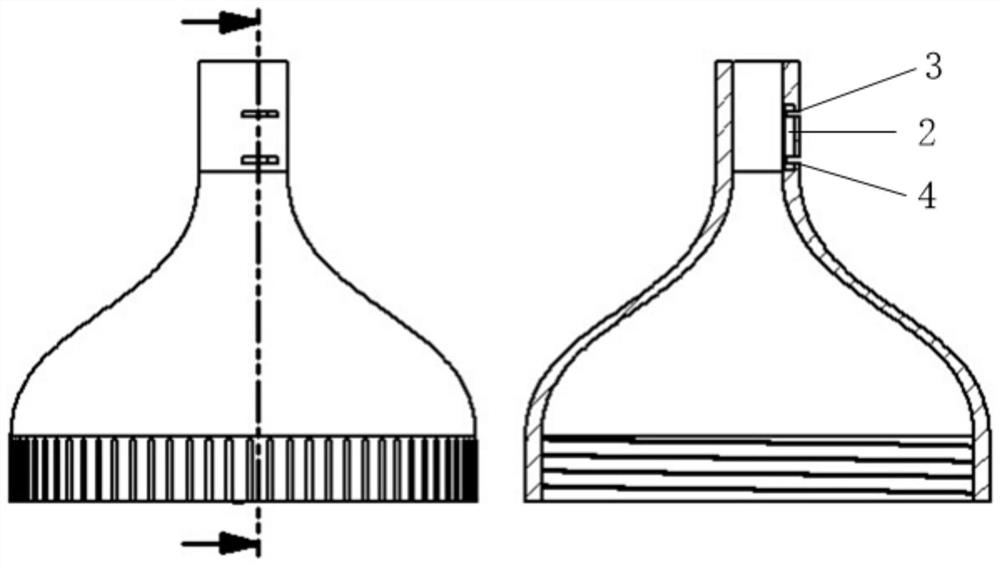

[0024] Such as Figure 1-3 As shown, the toner filling cap of this embodiment is used to adapt to the ink bottle of the printer, and solves the technical problem that toner clogging is very easy to occur when filling toner.

[0025] Specifically, the toner filling cap of this embodiment has a funnel-shaped filling cap main body, and a vibrating element is attached to the filling cap body, and the vibrating element vibrates to evacuate toner clogging when adding toner.

[0026] The toner filling cap of this embodiment is designed as a non-disposable consumable, and a thread 5 is designed on the inner peripheral side of the bottom of the filling cap, which can be adapted to the caliber of conventional ink filling bottles on the market, and can be purchased directly without a funnel. For the ink bottle, the toner can be filled by directly installing the toner filling cap, which can be reused, which is convenient and environmentally friendly. At the same time, the ink filling bott...

Embodiment 2

[0032] The difference between the toner filling cap of the present embodiment and the first embodiment is that:

[0033] Such as Figure 4 As shown, there is a protrusion on the outside of the filling cap in this embodiment, and the vibrating element is attached to the protrusion, and the mold is used for integral molding during production and processing. The design of the protrusion can be embedded into a larger vibrating element to enhance the vibration. At the same time, the cost of components can be reduced. Correspondingly, the switch slot and / or the charging slot are preferably opened on the protrusion.

[0034] For other structures, refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com