Double-sided battery back electrode and preparation method and application thereof

A back electrode, double-sided battery technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing manufacturing costs and not being able to be promoted in batches, and achieve the effect of reducing height, shortening current collection paths, and reducing limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

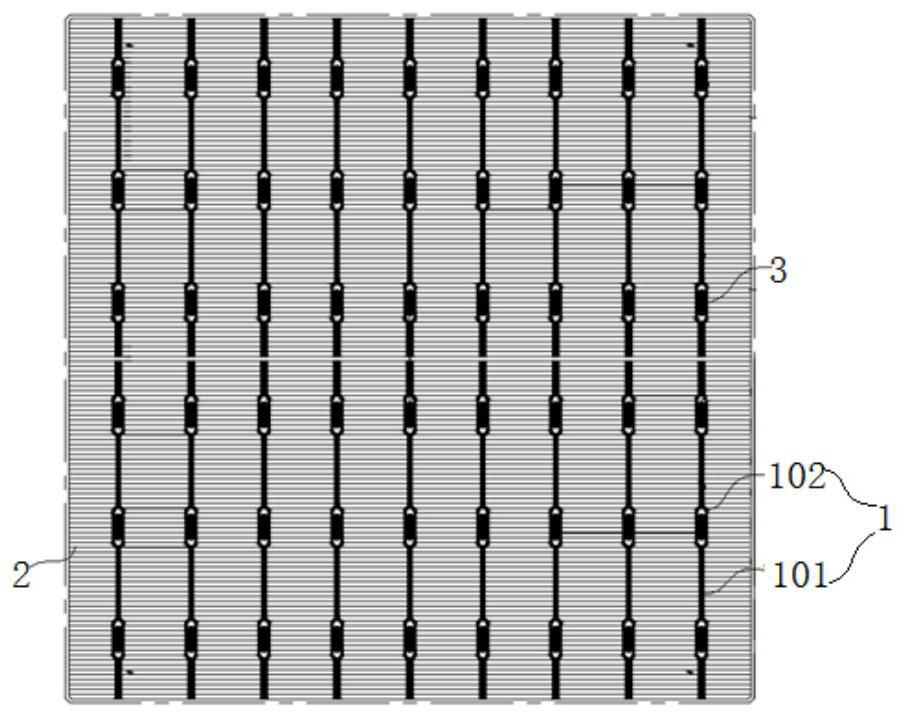

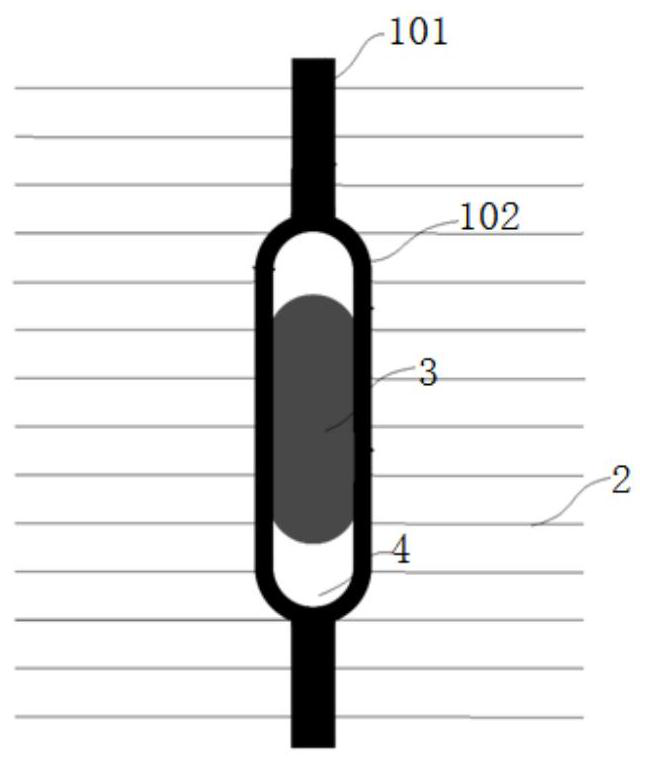

[0051] The double-sided battery of the present embodiment includes an aluminum main gate 1 and an aluminum sub-grid 2, wherein the number of aluminum main grids 1 is 9, and the aluminum main grid 1 is provided with a ring type aluminum in which the interval spaced apart in length direction is provided. The main grid 102, and both ends of all ring type aluminum main grids 102 have two aluminum fine main grids 101 to exogenous design. The outer side of the rings-type aluminum main grid 102 is connected to the outer side of the aluminum fine aluminum side gate 201, and the inner side of the aluminum fine main grid 101 is connected to the vertical distribution of longitudinal aluminum sub-gate 202, Aluminum sub-gate 2 has a width of 100 μm, and adjacent transverse aluminum sub-grids 201 and adjacent longitudinal aluminum sub-gate 202 are 1.00 mm.

[0052] The inside of the ring type aluminum main grid 102 is provided with a back silver electrode 3, and the number of segments of the ba...

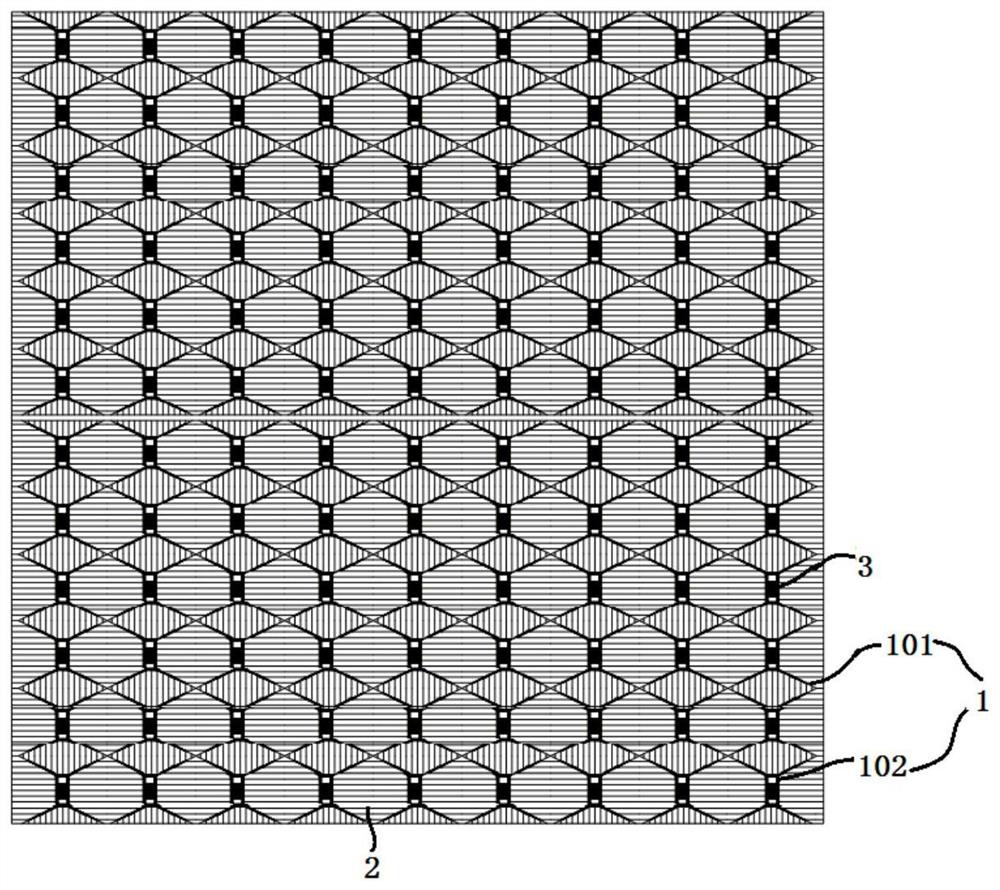

Embodiment 2

[0072] The double-sided battery of the present embodiment is substantially the same in the first embodiment, and the difference is mainly in that the number of the aluminum main grid 1 is 11, and the width of the aluminum sub-gate 2 is 60 μm, and adjacent lateral aluminum. The spacing of the sub-gate 201 and adjacent longitudinal aluminum side 202 is 0.8 mm. In this embodiment, the number of segments of the back silver electrode 3 on the same main grid is 8, which is 1.2 mm, which is 5.4 mm in length, and the ring type width of the ring type aluminum main grid 102 is 0.6mm, and the inner ring width is 1.0. MM, the inner ring length is 5.8 mm. The aluminum fine main grill uses 0.5 mm / 0.42 mm / 0.10 mm three-stage bamboo gradient structure.

[0073] The method of preparing the double-sided battery according to the present embodiment is substantially the same as in Example 1, and the difference is that the square resistance of the positive surface of the positive surface is 120 Ω / ...

Embodiment 3

[0075] The double-sided battery of the present embodiment is substantially the same in the first embodiment, and the difference is mainly in that the number of the aluminum main grid 1 is 15, and the width of the aluminum sub-gate 2 is 200 μm, and adjacent lateral aluminum The spacing of the sub-gate 201 and adjacent longitudinal aluminum sub-gate 202 is 1.5 mm. In this embodiment, the number of segments of the back silver electrode 3 on the same main grid is 14, which has a width of 1.8 mm, a length of 3.5 mm, and the ring type width of the ring aluminum main grid 102 is 0.5mm, and the inner ring width is 1.6. MM, the inner ring length is 4.2mm. The aluminum fine main grill uses 0.8 mm / 0.55 mm / 0.22 mm three-stage bamboo stewardal structure.

[0076] The method of the double-sided battery of the present embodiment, the process operation is substantially the same as in Example 1, and the difference is mainly in that the square resistance of the positive surface of the positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com