Type-C connector structure and production process thereof

A joint structure, the same end technology, applied in the direction of fixed/insulated contact members, connections, parts of connecting devices, etc., can solve the problems affecting product ejection and yield, complex structure, complicated mold design, etc., to improve the ejection rate. , The effect of simplifying the internal structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

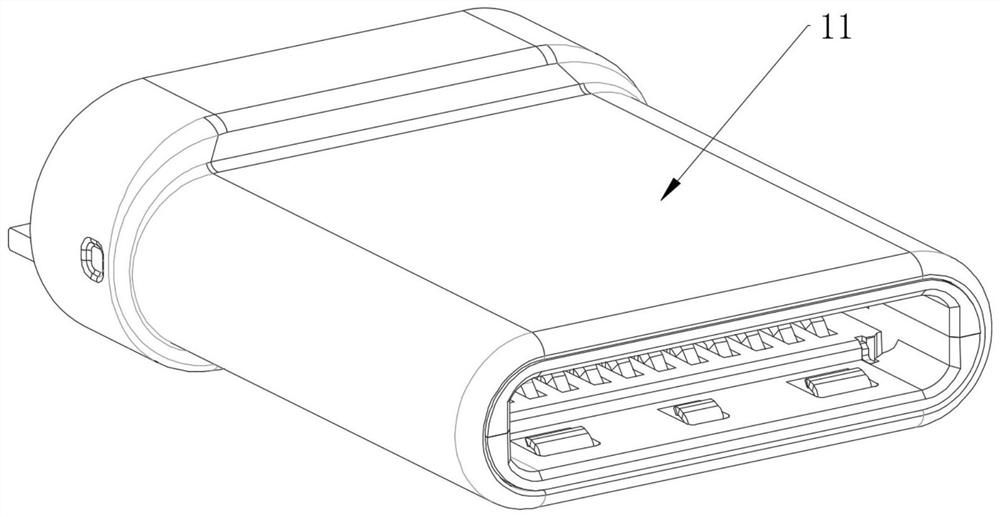

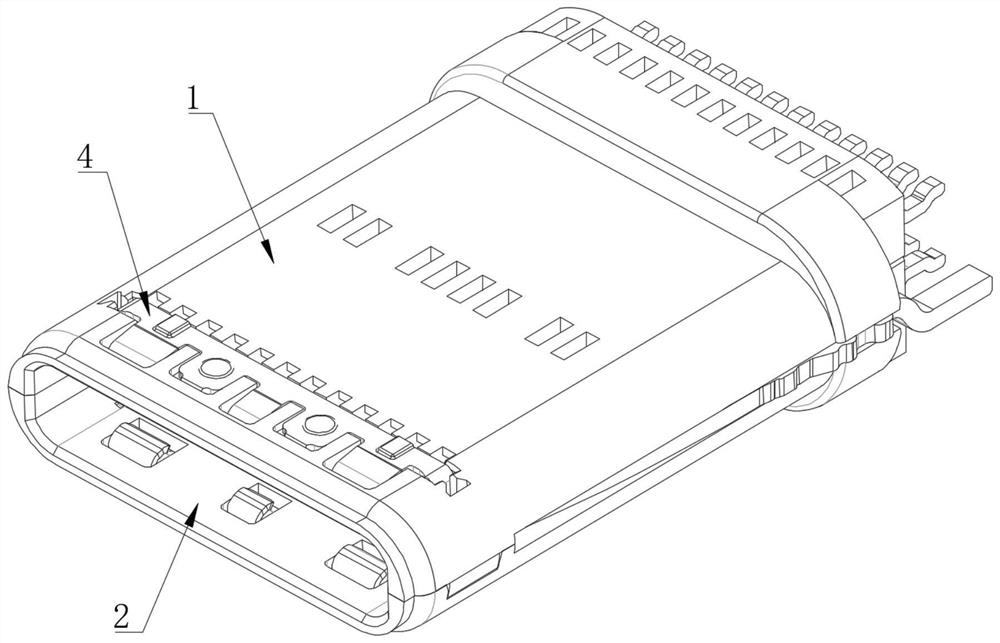

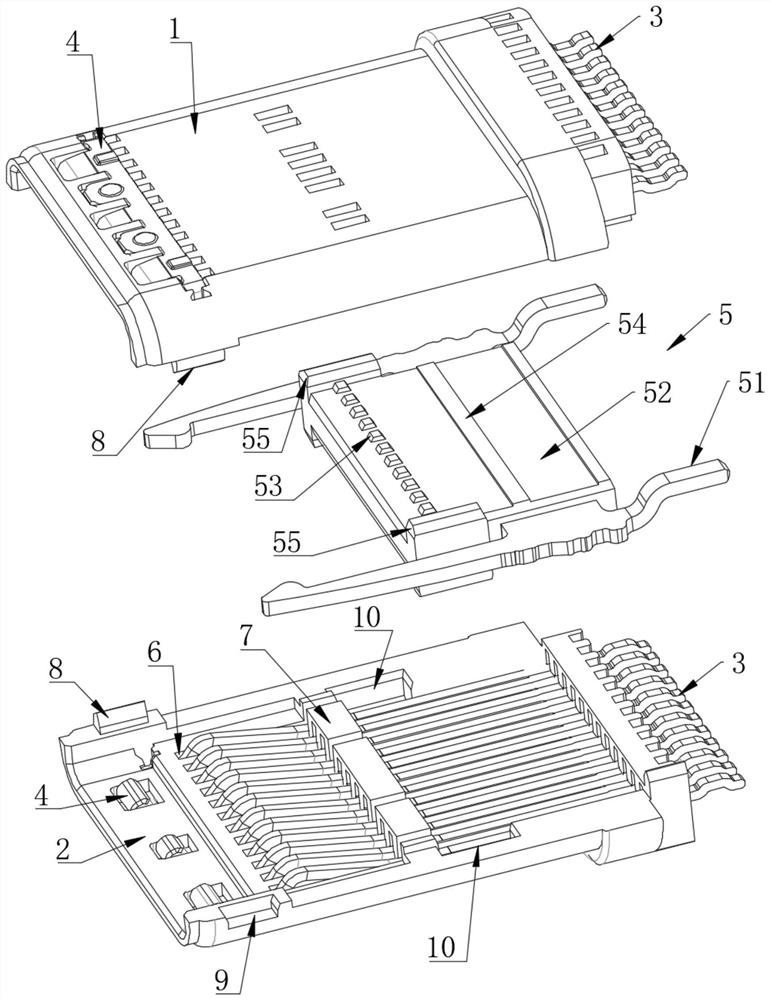

[0032] Example 1: A Type-C connector structure, see Figure 1 to 4 The first rubber shell 1 and the second rubber case 2 including a mirror symmetrical mounted, the first rubber shell 1 and the inner wall of the second rubber housing 2 are respectively mounted with a row correspondingly provided terminal 3, the first The EMI sheet 4 is mounted in the same end of the adhesive shell 1 and the second rubber shell 2, and the first rubber shell 1 and the second rubber shell 2 are mounted to insulation and positioning two row terminals 3. The septum 5.

[0033] The first rubber shell 1 and the second rubber housing 2 mounted in a mirror symmetrical mounted, reducing the mold design structure, increase the mold rate, the product is higher, and by setting a septum 5, simultaneously playing up and down two rows The terminal 3 and the effect of the insulation simplifies the internal structure of the Type-C connector so that the structure is more compact.

[0034] In the present embodiment, t...

Embodiment 2

[0044] Example 2: A Type-C connector structure production process, including the following steps:

[0045] S1, the two rows of terminals and two EMI sheets are mounted on the upper and lower inclusions;

[0046] S2, mount the middle spacer between the two rubber shells;

[0047] S3, assembled two rubber shells;

[0048] S4, ultrasonic welding two rubber shell;

[0049] S5, test by visual pairing device;

[0050] S6, give the outer casing through the test.

[0051] In the present embodiment, the terminal production uses a small Pith process, two terminals, reducing the risk of stamping die terminals, and improving the punching speed, and improve production efficiency.

[0052] Ultrasonic welding is more beautiful, better sealing; high detection efficiency is high, improved product yield; the production step is simple and easy to operate, and production efficiency is improved.

[0053] Preferably, the head of the terminal is bent and processed. This ensures that the terminal bullet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com