A full-digital homogeneous aeration sender

A homogeneous aeration and all-digital technology, which is applied in milk processing equipment, cream processing, food forming, etc., can solve the problems of low efficiency, long time of sending, and poor sending effect, so as to ensure quality, facilitate cleaning, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

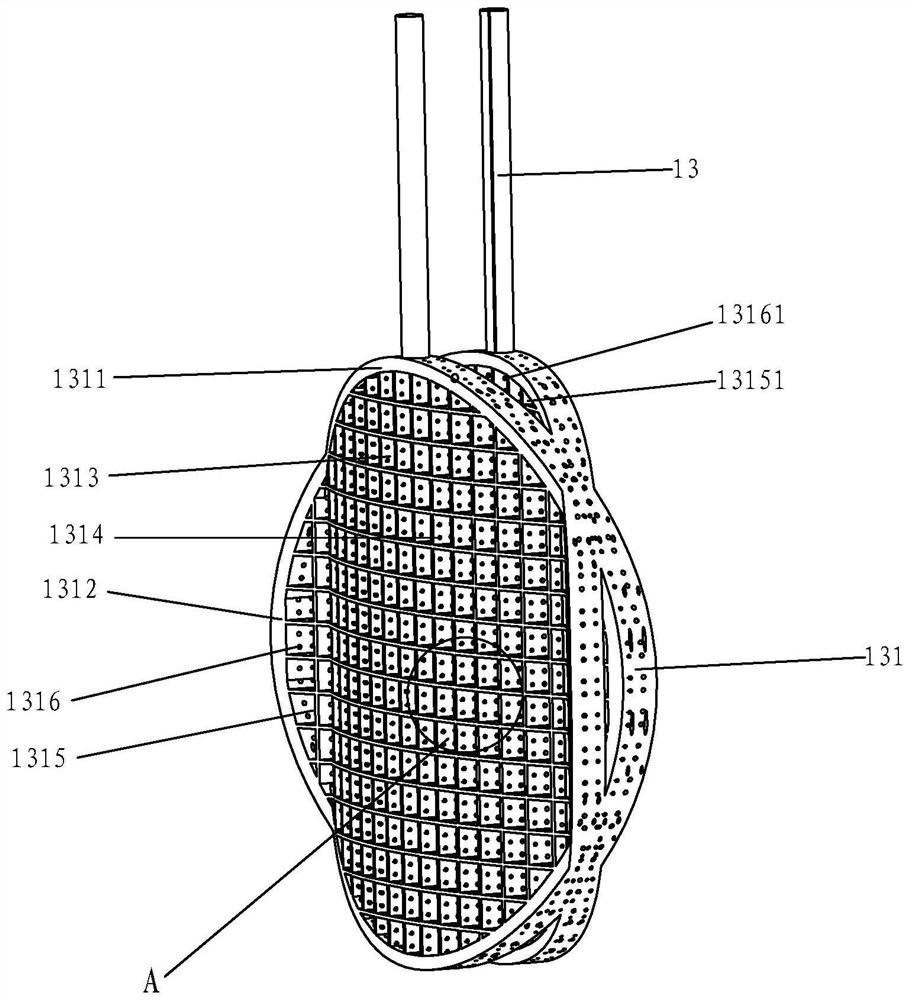

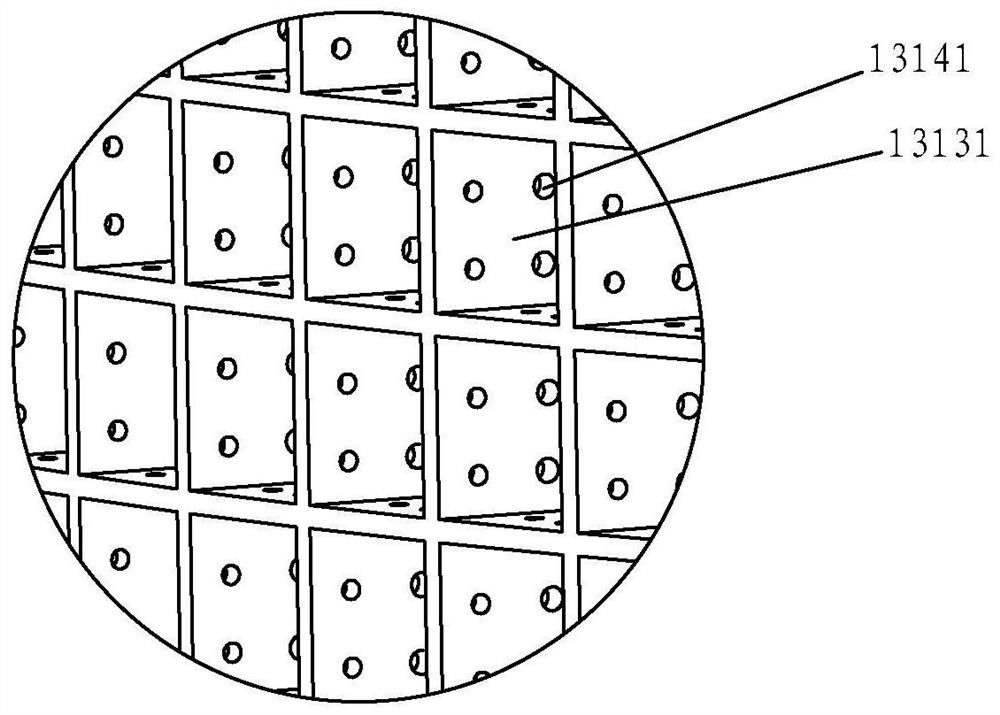

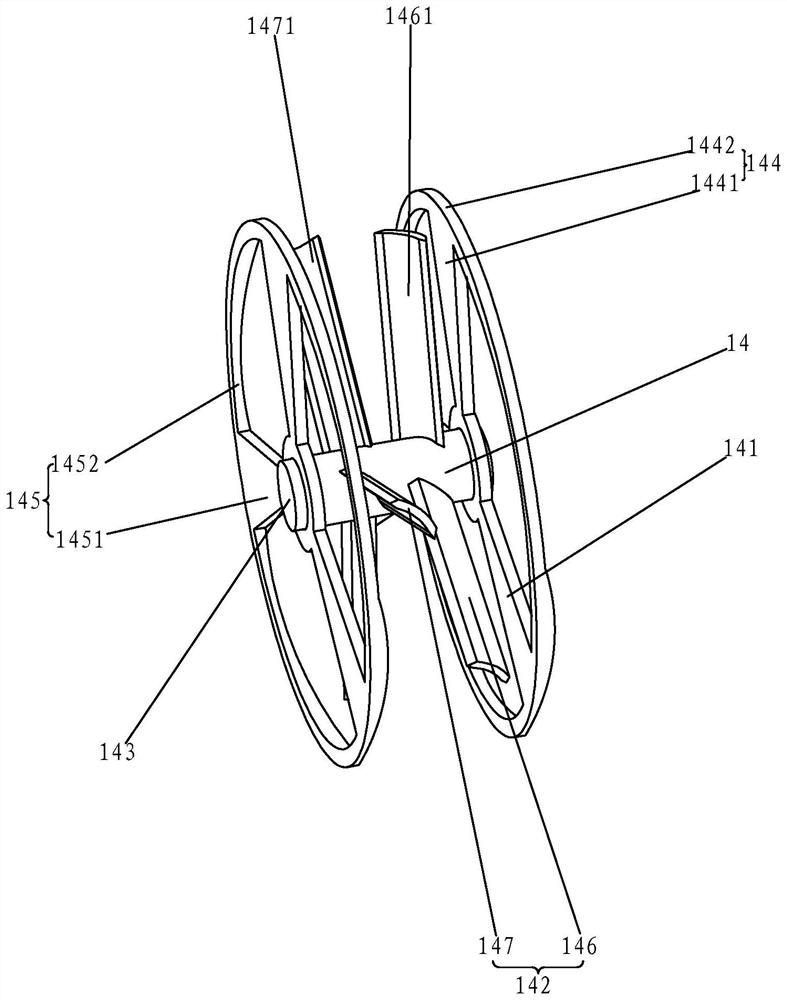

[0048] Such as Figure 1 to Figure 4 As shown, a fully digital homogeneous aerated sender of the present invention includes a sending device for sending a mixture; the sending device includes a first sending device 1 for sending a mixture; the first sending device 1 includes a first sending device for accommodating the mixture An accommodating mechanism 11, and a first sending mechanism 12 for sending the mixture; the first sending mechanism 12 includes a first inflation mechanism 13 for inflating the mixture; the first inflation mechanism 13 includes a first inflation unit for outputting gas to the mixture 131; the first inflatable part 131 includes a first inflatable part 1311 and a second inflatable part 1312; the first inflatable part 1311 is formed on the first inflatable part 1311 for the mixture to pass through the first feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com