Assembling method for filtering type fire-fighting self-rescue respirator

An assembly method and respirator technology, applied in the direction of respiratory protective containers, respiratory filters, respiratory masks, etc., can solve the problems of high labor intensity, low production efficiency, and affecting air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: A kind of assembly method of filter type fire-fighting self-rescue respirator.

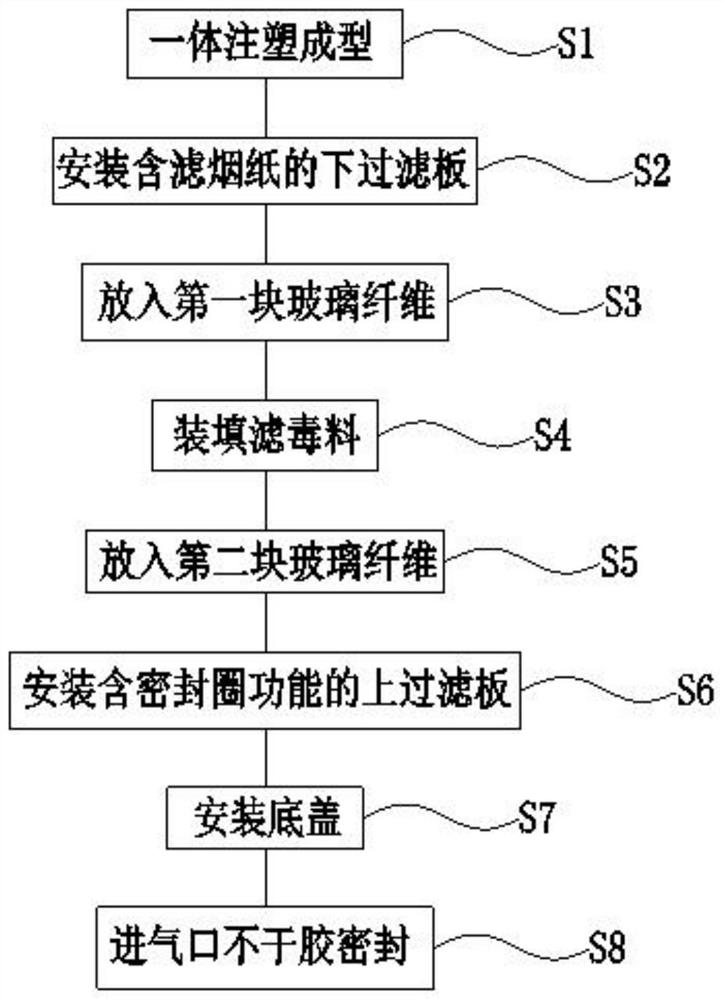

[0027] refer to figure 1 As shown, a filter type fire self-rescue respirator assembly method specifically includes the following steps:

[0028] S1. Integral injection molding: Design the half-mask, valve structure and canister of the product accessories as an integrated structure, and open the mold according to the design drawings of the integrated structure. In the traditional processing technology, the half-mask, valve seat, valve cover, etc. are made of rubber The parts and the canister are stainless steel parts, which need to be independently processed and then assembled. During the assembly process, it is easy to cause unstable assembly and poor airtightness due to human factors, and the processing equipment for each part is different, resulting in a wide variety of equipment. There are also many people who need to operate, and the required site covers a large area. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com