Steel plate shearing device and using method

A shearing device, cutting device technology, applied in shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the problems of low degree of automation, affecting work efficiency, sheet scattering, etc., to improve the degree of automation, improve Work efficiency, continuous cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

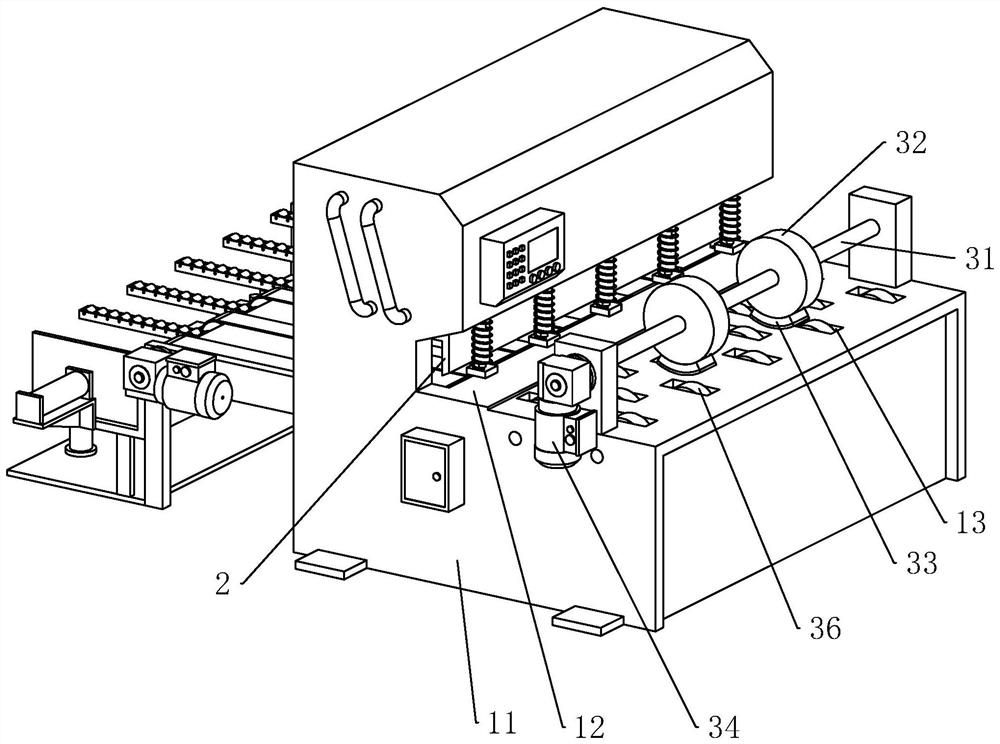

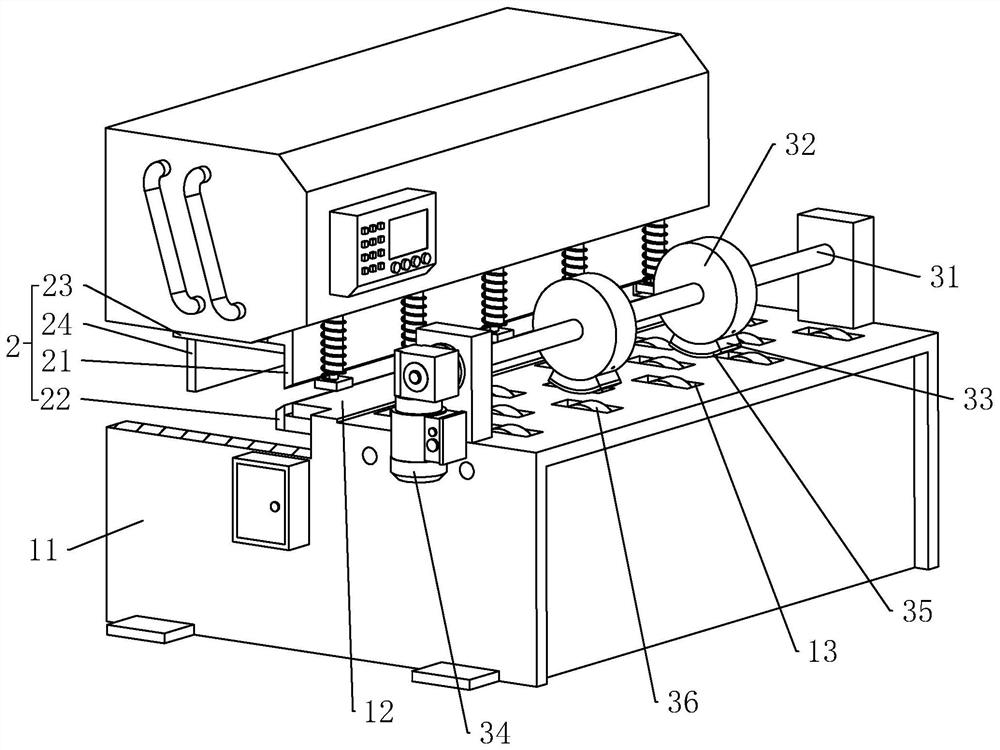

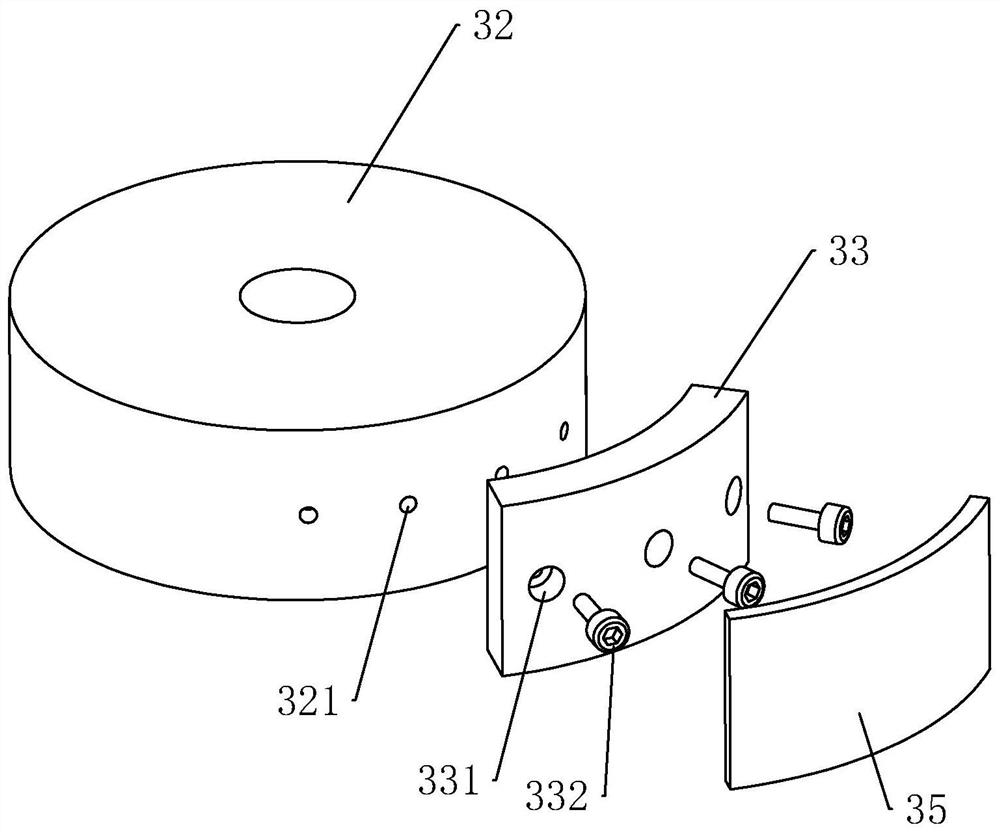

[0057] The application will be described in further detail below in conjunction with the accompanying drawings.

[0058] In order to facilitate the understanding of the technical solution of the present application, the shearing process of the steel plate is first briefly introduced. When the steel plate is loaded, the steel plate is pushed to the bottom of the cutter, and the hydraulic system drives the cutter to cut the steel plate. The sheared steel plate Slide down to the rear of the rack. In the whole process, first of all, when the steel plate is loaded, it is necessary to continuously push the steel plate forward. Even if the pneumatic device is used to push the steel plate to move intermittently, after each steel plate is cut, the pneumatic device needs to return to its position and adjust its posture before placing the next steel plate. The continuous shearing operation of the steel plate cannot be realized; after the steel plate is sheared, it is scattered at the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com