Apparatus and method for evaluating shear resistance of polymer solution

A technology of polymer solution and evaluation device, applied in measurement device, flow characteristics, instrument and other directions, can solve the problems of inability to simulate the shear resistance evaluation of polymer solution, complicated assembly and disassembly process, and large sample volume of polymer solution, etc. Achieve the effect of saving experimental time, low device cost and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

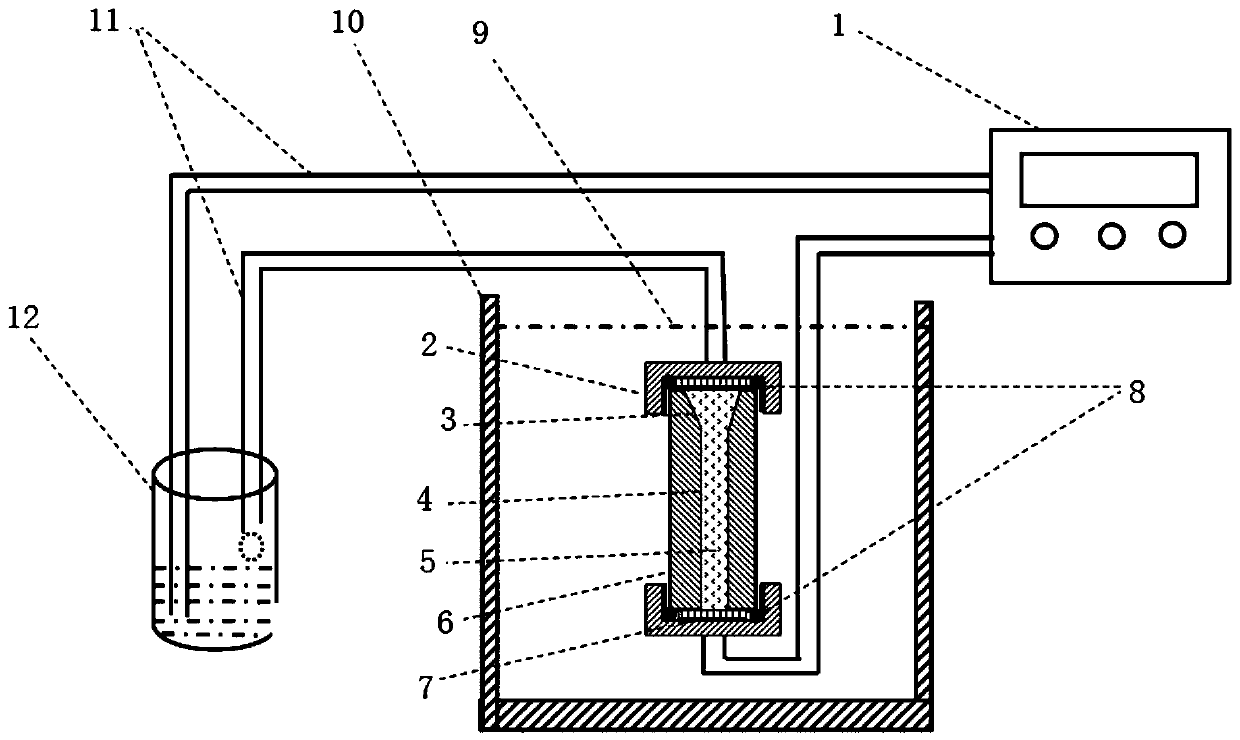

Method used

Image

Examples

Embodiment 1

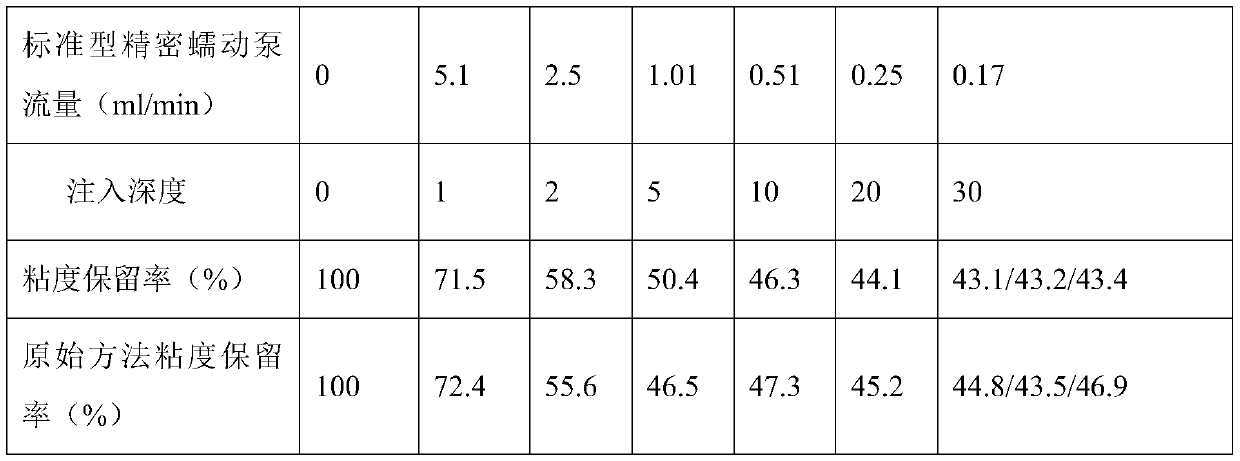

[0045] The method of the present invention is used to simulate and evaluate the viscosity retention rate of the polymer solution injected into the formation at a depth of 30 meters under the condition of 30°C.

[0046] A commercially available constant temperature water bath device. The temperature is adjustable from 20 to 80°C, and the temperature control accuracy is ±2°C. Internal height is 200mm.

[0047] One set of commercially available standard precision peristaltic pump, flow range 0.07-16mL / min, pipe joint (outer diameter 10mm), connecting hose (13#, 14#), external control module (0-5V for external signal control peristaltic pump drive revolutions).

[0048]Configure 50mL of a 1500mg / L polyacrylamide (molecular weight: 25 million, hydrolysis degree: 18%) solution, measure the initial viscosity at a temperature of 30°C, and place the solution in a beaker. The initial viscosity is 54.5mPa.s.

[0049] Fill the quartz sand into the sand-filling tube to prepare the core ...

Embodiment 2

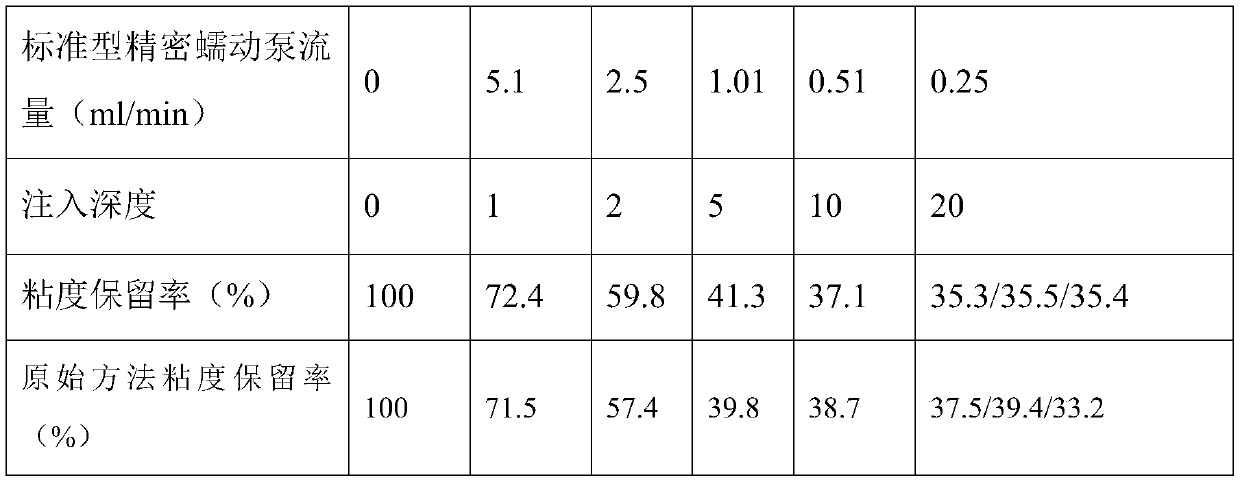

[0061] The method of the present invention is used to simulate and evaluate the viscosity retention rate of the polymer solution injected into the formation at a depth of 30 meters under the condition of 80°C.

[0062] Commercially available constant temperature water bath. The temperature is adjustable from 20 to 80°C, and the temperature control accuracy is ±2°C. The internal length is 300mm.

[0063] One set of commercially available standard precision peristaltic pump, flow range 0.07-16mL / min, pipe joint (outer diameter 10mm), connecting hose (13#, 14#), external control module (0-5V for external signal control peristaltic pump drive revolutions).

[0064] Configure 50mL of a 1500mg / L polyacrylamide (molecular weight: 25 million, hydrolysis degree: 18%) solution, measure the initial viscosity at 80°C, and place the solution in a beaker. The initial viscosity is 54.5mPa.s.

[0065] Fill the quartz sand into the sand-filling tube to prepare the core of the sand-filling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com