Control valve and water heater circulating system

A technology for controlling valves and water heaters, which is applied in the field of valve structures, and can solve problems such as misstarting of water heaters 90, shortening the service life of water heaters 90, increasing user costs, and achieving the effect of avoiding false starts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

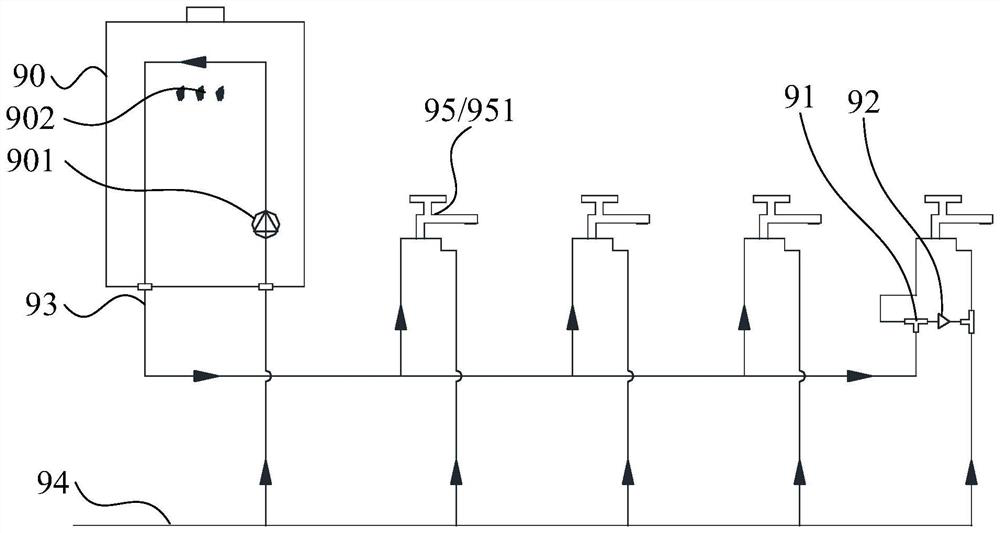

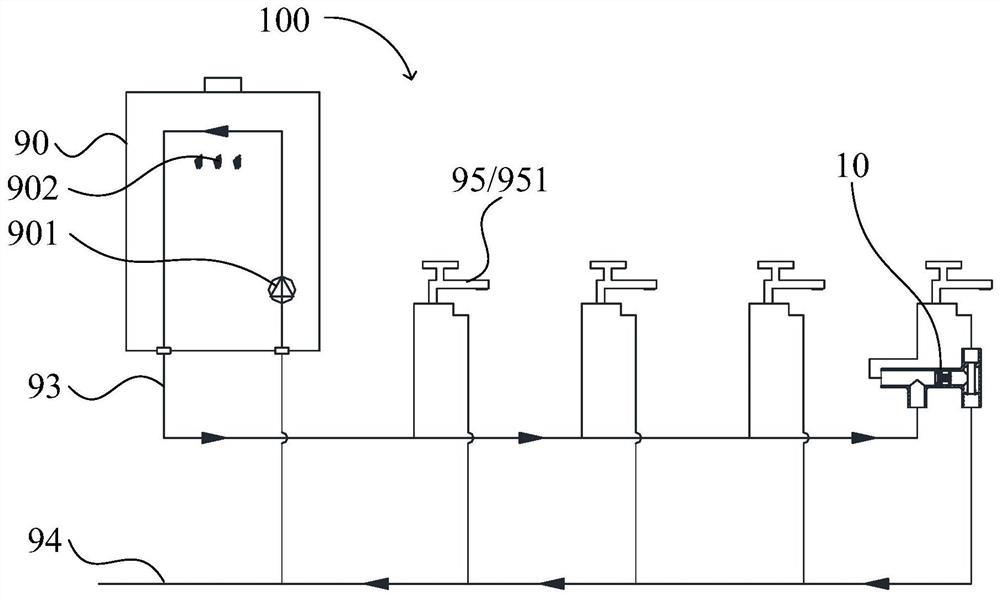

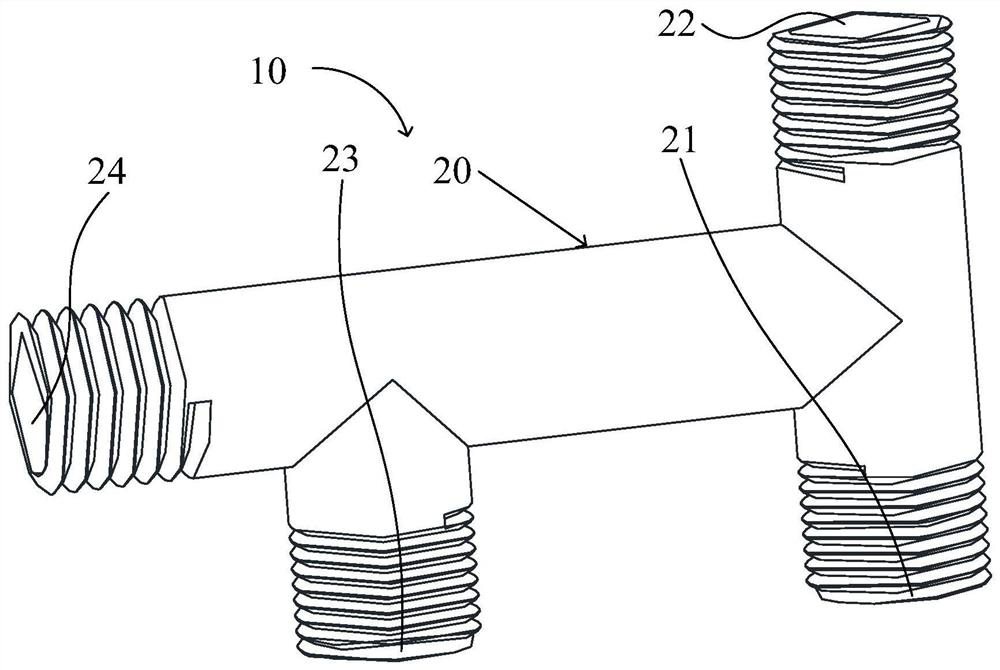

[0171] Such as Figure 2 to Figure 14 As shown, the present embodiment is a water heater circulation system 100, which includes a water heater 90, a hot water pipeline 93, a cold water pipeline 94 and several water terminals 95, and the water terminals 95 pass through the hot water pipeline 93 and the water outlet of the water heater 90. The cold water pipeline 94 communicates with the water inlet and the water end 95 of the water heater 90 respectively; the water heater circulation system 100 also includes a control valve 10 as follows, the cold water pipeline 94 communicates with the first communication port 21, and the second communication The port 22 communicates with the water port 95, and the third communicating port 23 communicates with the hot water pipe.

[0172] In the water heater circulation system 100 of this embodiment, by connecting the cold water pipeline 94 with the first communication port 21, the second communication port 22 with the water end 95, and the ho...

Embodiment 2

[0219] Such as Figure 16 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the spool 30 of this embodiment is as Figure 16 shown. Such as Figure 16 Only the valve core 30 located in the valve body 20 and the first communication port 21 , the second communication port 22 and the third communication port 23 of the valve body 20 are shown, and other components are not shown.

[0220] exist Figure 16 Among them, the valve core 30 includes a blocking plate 421 , a driving plate 411 and a pivot shaft 31 . At least part of the blocking plate 421 is located in the flow space of the first fluid, and the blocking plate 421 is disposed close to the third communication port 23 . The blocking plate 421 and the driving plate 411 may be directly connected, and the pivot shaft 31 is located at the intersection of the blocking plate 421 and the driving plate 411 . Cold water can flow upward from the first communication port 21 to the second commun...

Embodiment 3

[0222] Such as Figure 17 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the flow guiding part 50 of this embodiment is a partition 53, such as Figure 16 shown. Such as Figure 16 Only the valve core 30 located in the valve body 20 and the first communication port 21 , the second communication port 22 and the third communication port 23 of the valve body 20 are shown, and other components are not shown.

[0223] The guide part 50 is a partition 53, one side of the partition 53 and the corresponding inner surface of the valve body 20 form the first passage 25; the other side of the partition 53 and the corresponding inner surface of the valve body 20 form the first passage 25. The deflector 50 is configured as a partition 53, which has a simple structure and is convenient to form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com