A power grid troubleshooting equipment

A power grid fault and equipment technology, applied in the power grid field, can solve the problems of incomplete detection of the internal structure of the cable and the inability of the probe to fit completely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

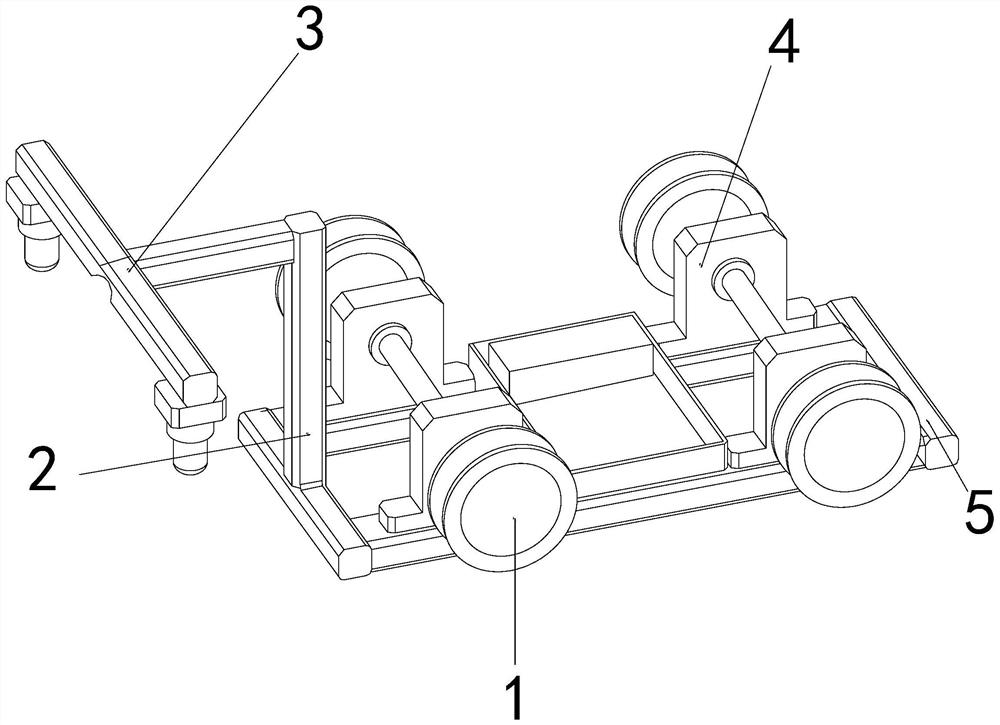

[0025] as attached figure 1 to the attached Figure 5 As shown in the figure, the present invention provides a power grid fault maintenance equipment, the structure of which includes a movable wheel 1, a vertical rod 2, a detection device 3, a fixed seat 4, and a bottom plate 5, and the left inner wall of the movable wheel 1 is connected by a connecting rod. At both ends of the fixed seat 4, the lower end of the vertical rod 2 is welded and fixed to the upper front end of the bottom plate 5, the rear end of the detection device 3 is movably engaged with the front end of the vertical rod 2, and the lower end of the fixed seat 4 is fixed to the upper end of the bottom plate 5 by screws;

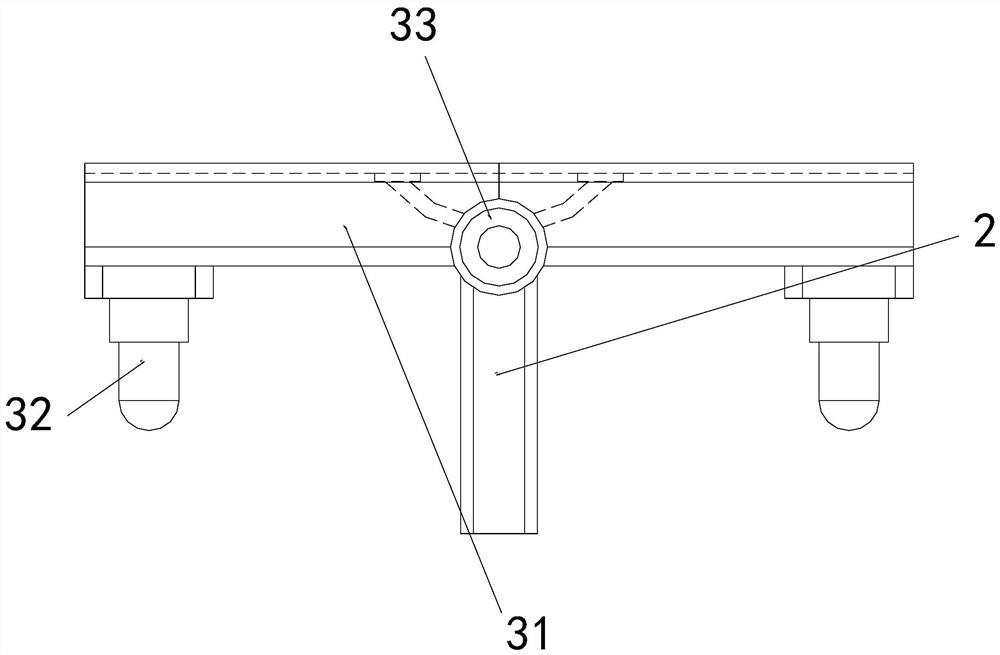

[0026] The detection device 3 is composed of a cross bar 31, a detector 32, and a hinge mechanism 33. The rear end of the cross bar 31 is movably engaged with the front end of the vertical bar 2, and the upper end of the detector 32 is connected to the horizontal bar through snap engagement. B...

Embodiment 2

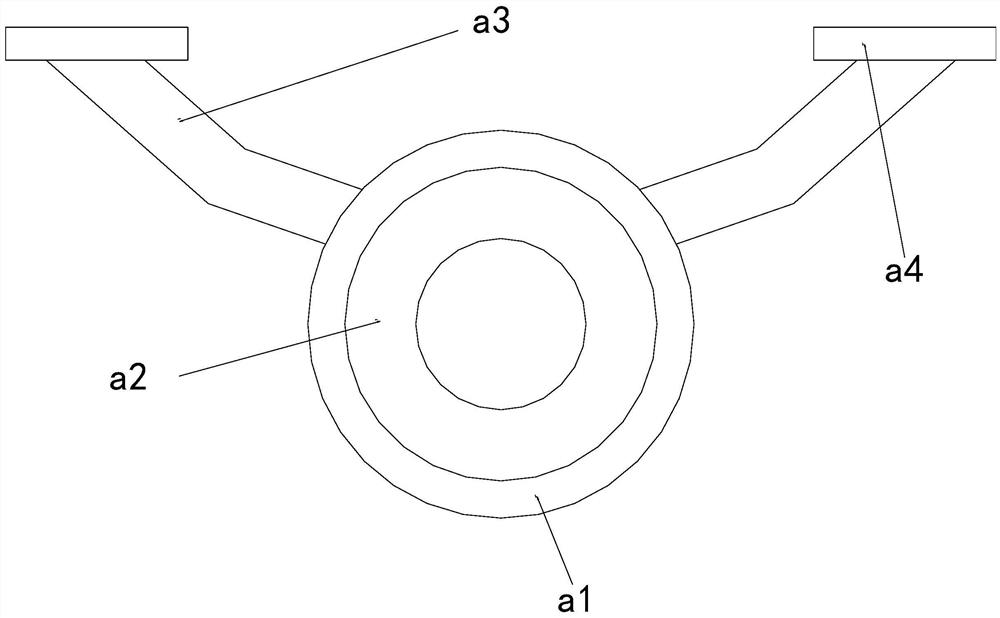

[0032] as attached Image 6 to the attached Figure 7 As shown: the detector 32 is composed of a sleeve shaft d1, an embedded connecting plate d2, and a detector d3. The upper end outer wall of the sleeve shaft d1 is fixed to the lower end of the embedded connecting plate d2 by screws, and the upper end of the detector d3 is movable. Coupling with the lower end of the connecting sleeve shaft d1, the upper end of the embedded connecting plate d2 is connected to the lower part of the two ends of the cross bar 31 through snap-fit.

[0033] The detector d3 is provided with a probe needle e1, a lift rod e2, a magnetic ring e3, a piston ring plate e4, and an empty groove e5. The inner wall of the upper end of the probe needle e1 is embedded and fixed on the lower end of the lift rod e2. The outer wall of the upper end of the rod e2 is interference-fitted with the inner wall of the magnetic ring e3, the inner wall of the piston ring plate e4 is nested and engaged with the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com