Servo driver and operation method thereof

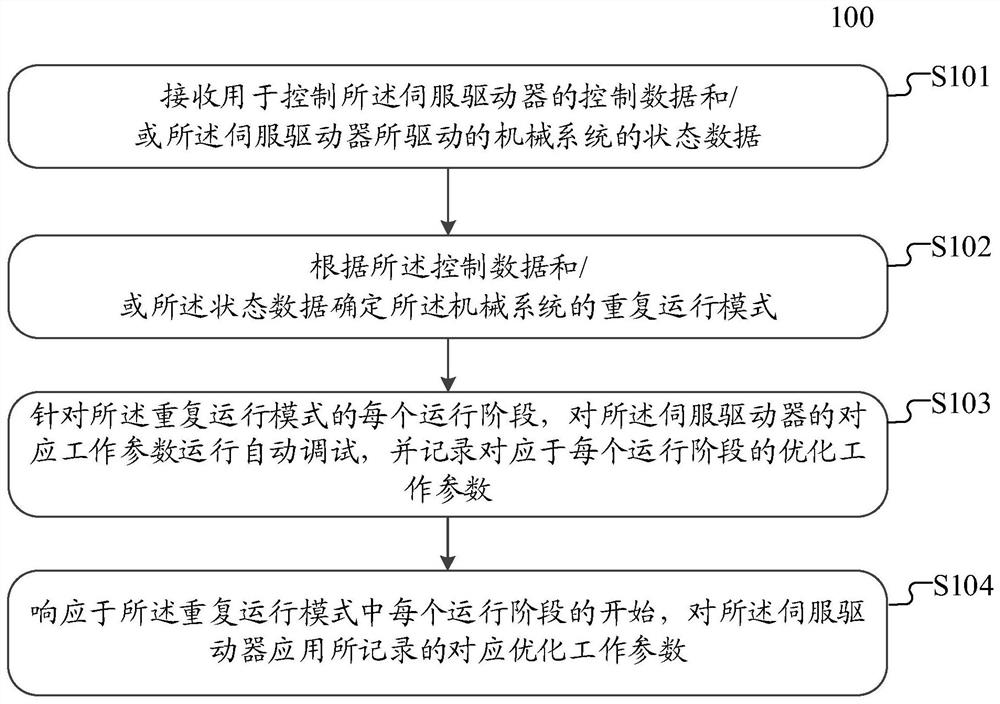

A technology of servo drive and operation method, which is applied in the field of servo drive, can solve the problems of servo drive work, inappropriate working parameters, and difficult optimization of working parameters with automatic debugging function, so as to achieve the effect of optimizing working parameters and fast working parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present disclosure will be described in detail with reference to exemplary embodiments of the present disclosure. However, the present disclosure is not limited to the embodiments described herein, and it may be embodied in many different forms. The described embodiments are only intended to make the present disclosure thorough and complete, and fully convey the concept of the present disclosure to those skilled in the art. Features of the various described embodiments can be combined or substituted for each other, unless explicitly excluded or should be excluded according to the context.

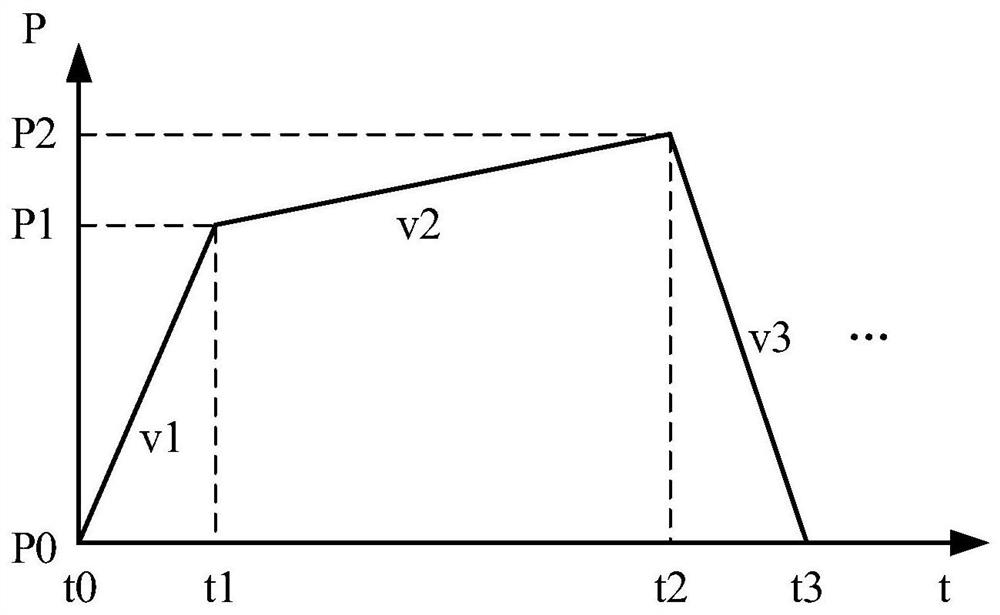

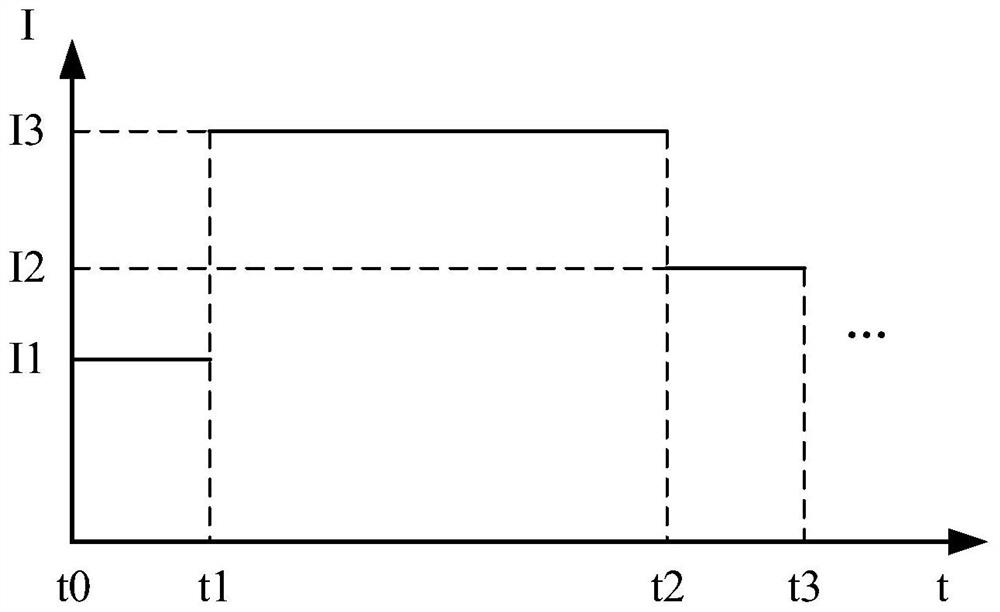

[0020] The servo drive with automatic debugging function can automatically find the optimized working parameters during operation, such as PID parameters, so it can automatically achieve the best working state. However, in some occasions, the operating state of the mechanical system driven by the servo drive will change, such as load or inertia. In this case, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com