Method for manufacturing polarizing plate

A polarizing plate and polarizing film technology, applied in chemical instruments and methods, optics, layered products, etc., can solve problems that affect the performance of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

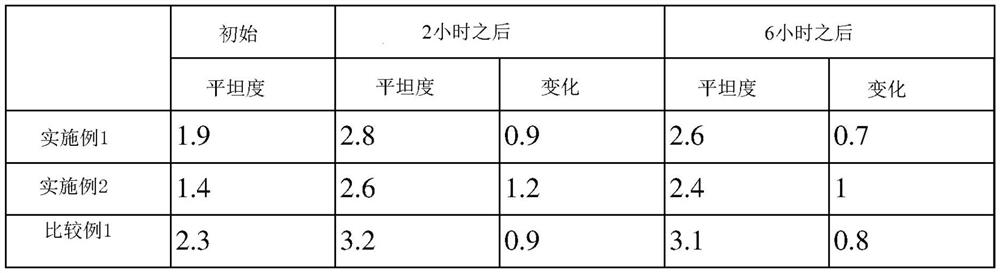

Embodiment 1

[0162] Heat Treatment of Polymer Films

[0163] For PET (polyethylene terephthalate) polymer film (SRF film, thickness: 80 μm, manufacturer: Toyobo, product name: TA055, glass transition temperature: 80°C, in the TD direction before heat treatment Shrinkage force: about 7.53N, shrinkage force in MD direction: in the range of about 0.1N to 0.5N), water treatment process first and then heat treatment. First, a water treatment process is performed by immersing the SRF membrane in water maintained at about 20° C. to 30° C. such that the whole is immersed therein, and then maintaining the SRF membrane for about 10 seconds to 20 seconds. Subsequently, heat treatment is performed by keeping the SRF film at a temperature of about 50° C. for about 10 seconds to about 60 seconds. After the heat treatment process, the shrinkage force of the SRF film in the TD (transverse direction) direction is about 7N, and the shrinkage force in the MD direction is at a level of about 0.2N to 0.35N. ...

Embodiment 2

[0169] Heat treatment was performed by keeping the SRF membrane water-treated in the same manner as in Example 1 at a temperature of about 100° C. for about 10 seconds to about 60 seconds. After the heat treatment process, the shrinkage force of the SRF film in the TD (transverse direction) direction is around 6.6N. A polarizing plate was produced in the same manner as in Example 1 using the SRF film. The shrinkage force of the produced polarizing plate along the MD direction of the polarizing film is about 8N, and the shrinkage force along the TD direction of the polarizing film is about 8.6N. As a result of obtaining the A value of the above formula 1 for the manufactured polarizing plate, it was about 4.17 Nmm to about 5.68 Nmm. In Equation 1, the lower limit of the value range of A is obtained by applying 0.86 as a, 0.25mm (=applied LCD panel thickness (mm) / 2) as b, and approximately 9N as S PVA , applying 6.6N as S Pro , apply 0.0395mm (= pressure sensitive adhesive th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contraction force | aaaaa | aaaaa |

| contraction force | aaaaa | aaaaa |

| contraction force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com