Sand aggregate continuous grading production system for high-performance concrete and process

A high-performance concrete and production system technology, applied in grain processing, etc., can solve problems such as insufficient material supply, scouring loss, and adverse effects on sand material quality, and achieve the goals of improving quality, continuously adjusting gradation, and increasing the adjustment range of output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

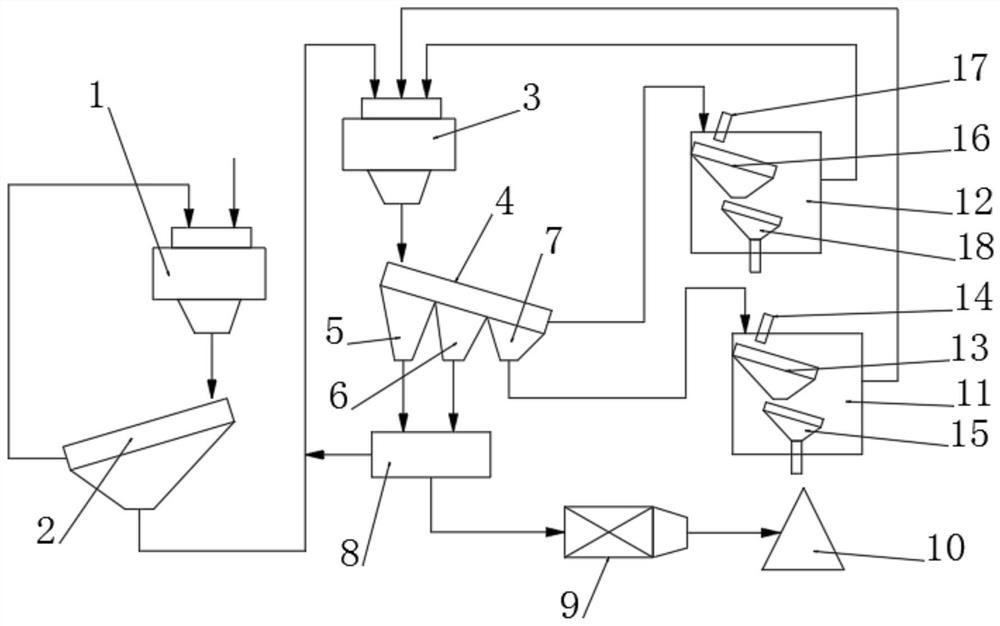

[0028] Such as figure 1 Shown is the structural representation of the present invention:

[0029] The invention provides a continuous grading production system of sand and gravel aggregates for high-performance concrete, which includes a secondary crushing unit 1, a return screen 2, a fine crushing unit 3, a classifying screen 4, a transition stockyard 8, a depowdering unit 9, a sand Bin 10, small stone bin 11, large rock bin 12, the intermediate crushing unit 1, return screen 2, fine crushing unit 3, and classifying screen 4 are connected sequentially through the conveyor belt, and the upper outlet of the return screen 2 is connected to the intermediate crushing unit through the conveyor belt. The entrance of the unit 1, the outlet on the sieve of the grading sieve 4 is connected to the large stone bin 12 through a conveyor belt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com