Self-cleaning drum screen

A trommel screen and self-cleaning technology, applied in the field of trommel sieves, can solve the problem of materials easily sticking to the inner wall of the trommel screen, and achieve the effect of reducing the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

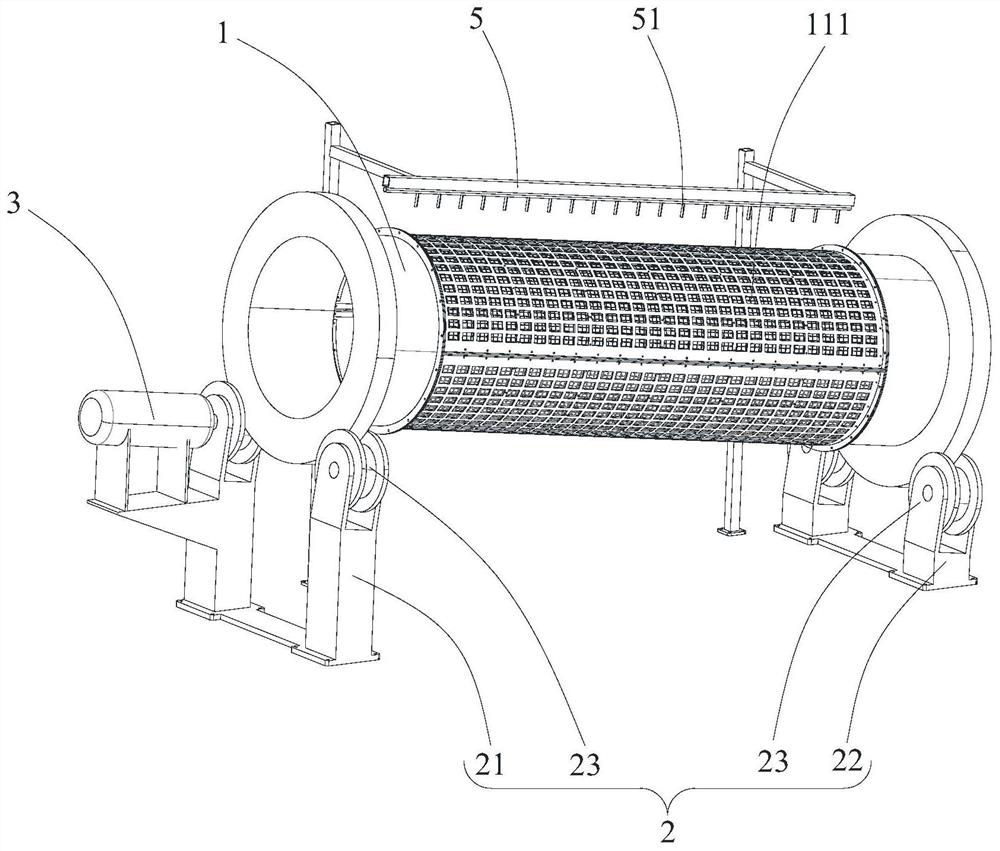

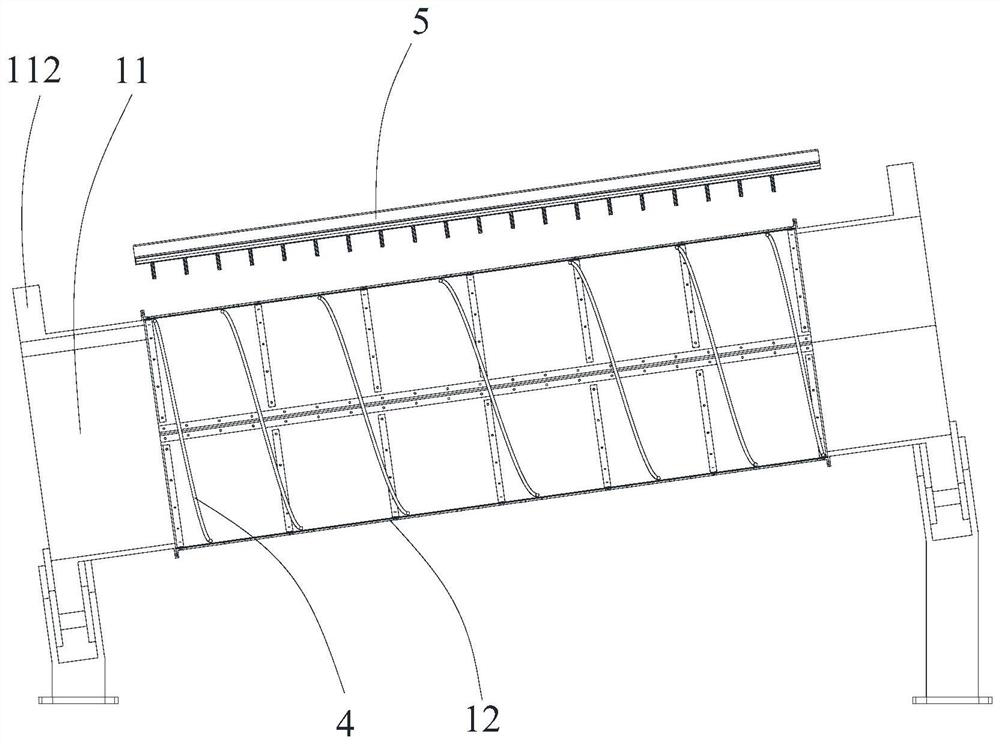

[0020] See figure 1 and figure 2 , The self-cleaning trommel screen includes a filter cylinder 1, a frame 2, a rotating mechanism 3, a guide body 4 and a spray device 5, which are used to wash materials and separate soluble substances and insoluble substances in the materials.

[0021] In this embodiment, the filter cartridge 1 includes a cylinder body 11 and a filter screen 12 . The cylinder 11 is a hollow cylinder, and inside the cylinder 11 there is a filter chamber connected to the two ends of the cylinder 11 along the axial direction, and the two ends form the inlet and outlet of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com