Sewage filtering and impurity removing device

A technology for filtering impurities and sewage, which is applied in the direction of filtration treatment, water/sewage treatment, grease/oily substance/floating matter removal device, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

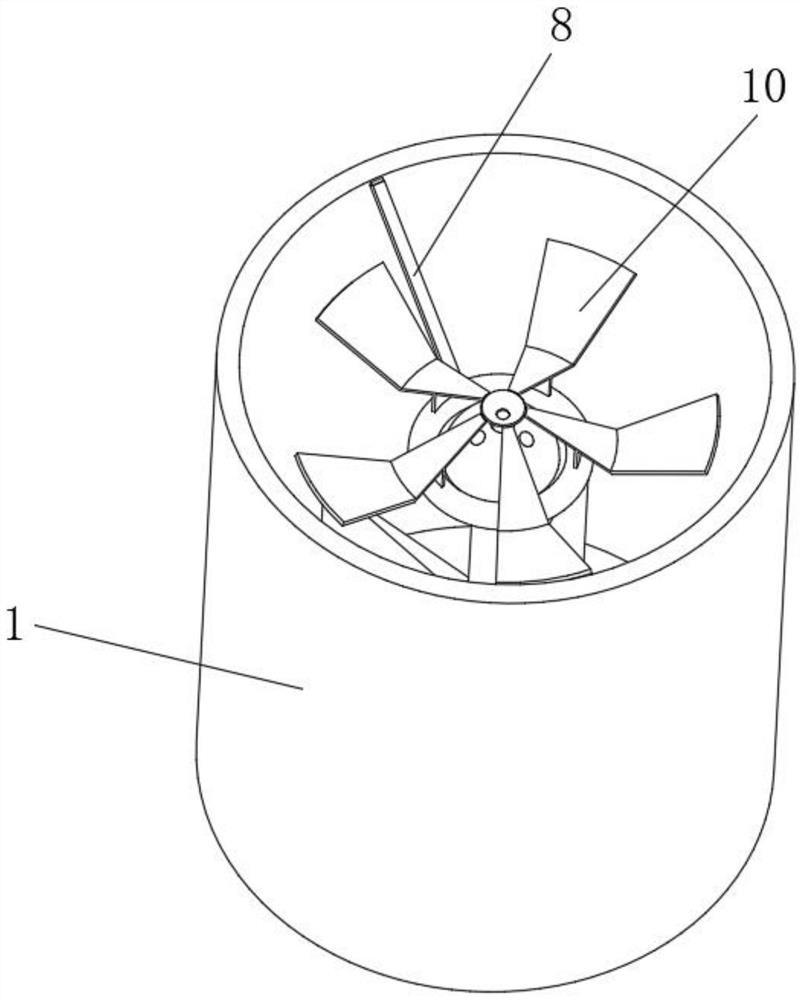

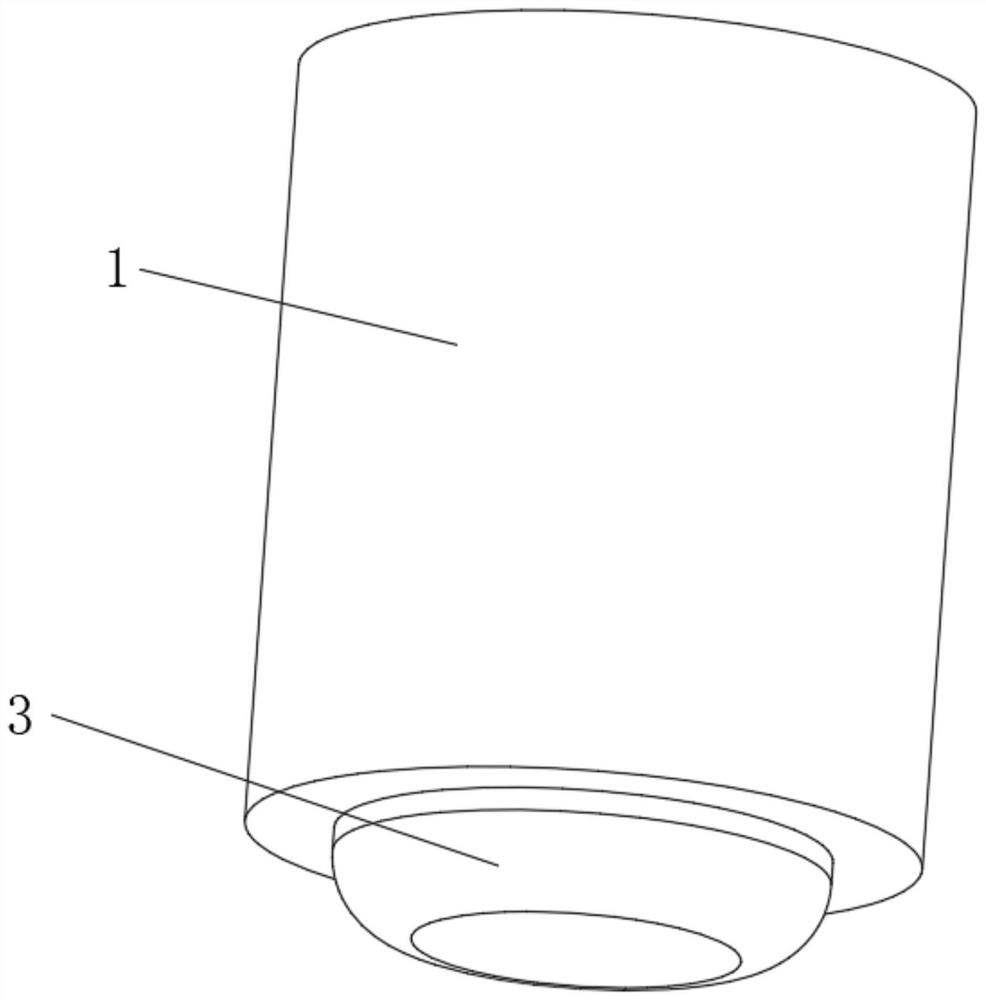

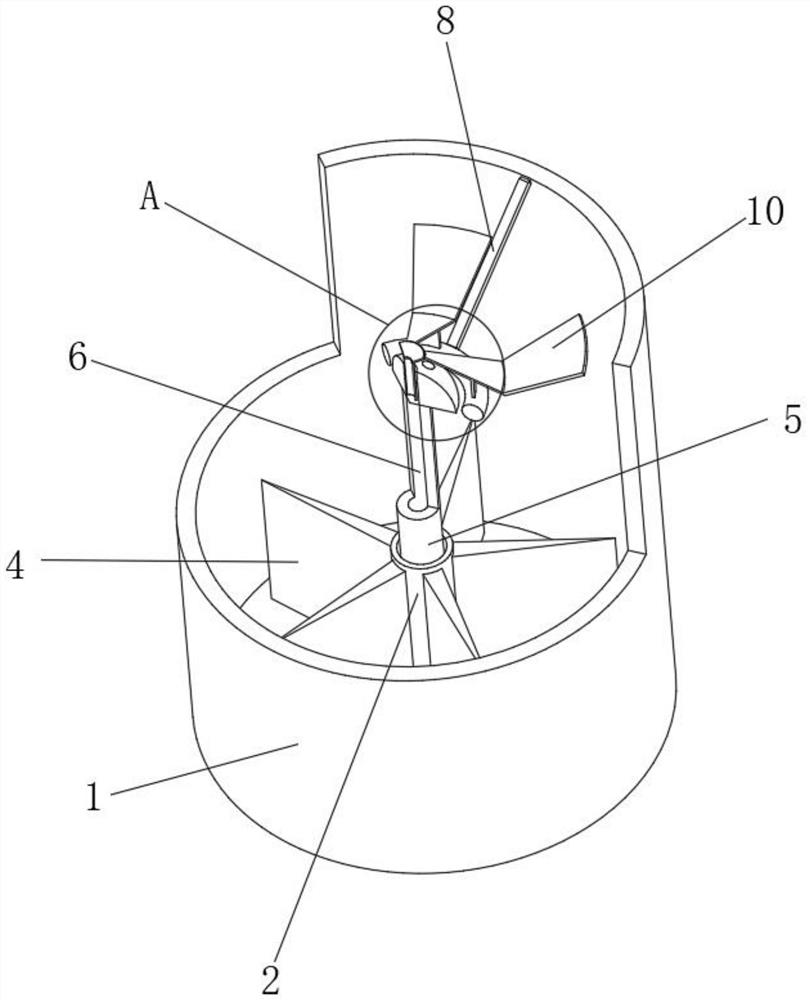

[0034] Such as Figure 1-4As shown, the present invention provides a technical solution: a sewage filtering and impurity removal device, including a filtering treatment barrel 1, the middle position of the inner bottom of the filtering treatment barrel 1 is rotatably connected with a drive insertion shaft 2, and the middle of the outer bottom of the filtering treatment barrel 1 The location is fixed and connected with a recovery groove 3, and the periphery of the outer surface of the driving insertion shaft 2 is uniformly and fixedly connected with a driving fan 4, and the inside of the top of the driving insertion shaft 2 is penetrated and slidably connected with a transmission insertion rod 5, and the bottom of the driving insertion shaft 2 is connected to the recovery slot. The interior of the groove 3 is connected, and the middle position inside the transmission insertion rod 5 is provided with a liquid guide inner tube 6. The top of the transmission insertion rod 5 away fr...

Embodiment 2

[0038] Such as Figure 5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a sewage filter and impurity removal device, the guide swing mechanism 10 includes a filter diverter plate 101, one end of the bottom of the filter diverter plate 101 and the floating carrier plate 9 Fixedly connected, the right side of the bottom end of the filter diverter plate 101 is rotatably connected with a contact separation plate 102 , and the inside of the contact separation plate 102 is uniformly provided with a buffer chute 103 .

[0039] A buffer inner groove 104 is uniformly arranged on the surface of the top of the filter splitter plate 101, a sealing cone groove 105 is fixedly connected to the position close to the left side of the separation plate 102, and a sealing plug piece 106 runs through and is slidably connected to the inside of the sealing cone groove 105. Avoid collisions to produce intense water splashes that affect the filtration and ...

Embodiment 3

[0043] Such as Figure 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a sewage filter and impurity removal device, the directional restriction assembly 109 includes a restriction baffle a1, a restriction baffle a1 and a filter diverter plate 101 Fixedly connected, one side of the limiting baffle a1 is fixedly connected with a guide buffer plate a2.

[0044] The inner surface of the guide buffer plate a2 is provided with a directional guide groove a3, and the top output end of the directional guide groove a3 is arranged correspondingly to the guide bucket groove 13. The purpose of avoiding the diversion of grease liquid to the outside and improving the efficiency of grease filtration and separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com