Friction stir welding process and superplastic forming process to achieve uniform superplastic forming of titanium alloy welded joints

A technology of friction stir and welded joints, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to show uniform deformation, low superplasticity, and deformation of the base material, and achieve high superplasticity and high elongation rate, reducing the effect of flow stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

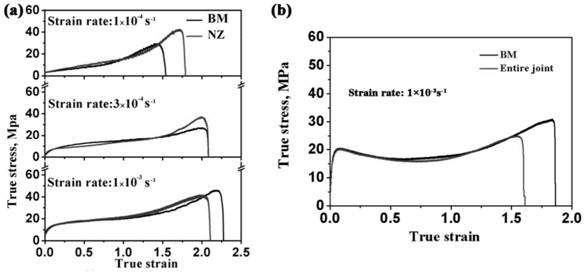

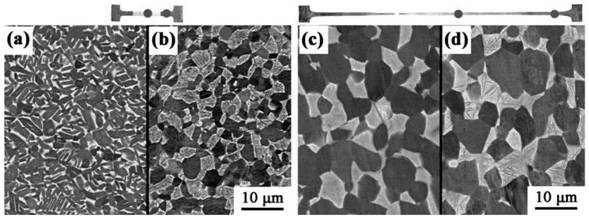

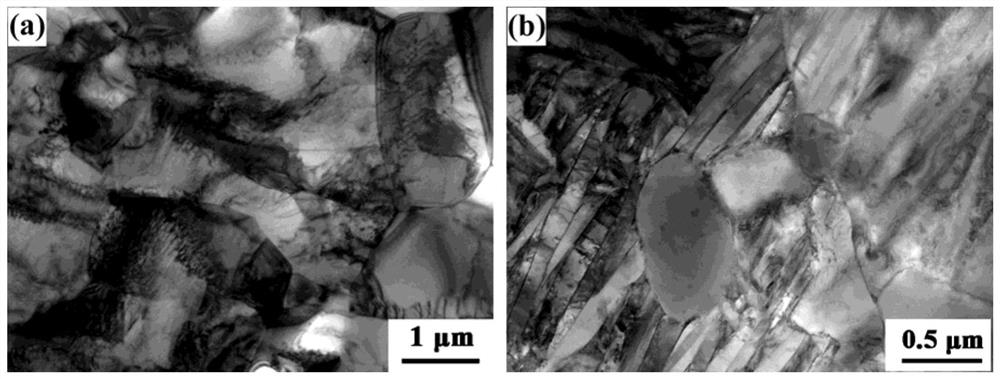

[0028] FSW welding of 2 mm thick as-rolled annealed Ti-6Al-4V alloy was performed using a tool shoulder diameter of 10 mm and a frustoconical W-15 wt% Re tip. During the welding process, the joint is protected with argon gas and the weld is rapidly cooled, and a water-cooled nickel-based superalloy backing plate is used to obtain high-quality welded joints under the welding parameters of tool speed of 400 rpm and travel speed of 100 mm / min . The joint structure is 20% of the initial α equiaxed grains + the secondary α structure of fine lamellae. The average sheet thickness and aspect ratio of the lamellar secondary α structure were 80 nm and 6:1, respectively. The high-temperature superplastic tensile test shows that when the superplastic temperature is 900 °C, the strain rate is 3 × 10 -4 s -1 When , the maximum elongation of the weld nugget is about 600%, and the elongation and flow stress of the weld nugget and the base metal are equivalent. The entire joint is at 900°C...

Embodiment 2

[0033] FSW was performed on a 2 mm thick as-rolled annealed Ti-6Al-4V alloy. Welding was performed with a W-25wt% Re alloy stirring head with a shoulder diameter of 11 mm, the joint was shielded with argon gas during welding and the weld was rapidly cooled, and the welding was performed at a tool speed of 500 rpm and a travel speed of 150 mm / min Under the parameters, WC-Co backing plate is used to obtain high-quality welded joints. The high-temperature superplastic tensile test shows that when the superplastic temperature is 900 °C, the strain rate is 1 × 10 -4 ~1×10 -3 s -1 When the weld nugget has an elongation of 400% or more, it is almost the same as the flow stress of the base metal, and the flow stress when the strain is 0.1% is 15MPa. The entire joint exhibits uniform superplastic deformation, and the joint organization tends to be consistent after the entire joint is uniformly deformed.

[0034] The tensile curve of the TC4 titanium alloy FSW weld nugget and base m...

Embodiment 3

[0038]FSW was performed using a 2 mm thick as-roll annealed Ti-6Al-4V alloy. Welding was performed with a W-25wt% Re alloy stirring tip with a shoulder diameter of 11 mm, the joint was shielded with argon gas during welding and the weld was rapidly cooled, and the welding was performed at a tool speed of 300 rpm and a travel speed of 50 mm / min Under the parameters, a nickel-based superalloy backing plate is used, and a circulating water-cooling backing plate is used to control the temperature of the welding seam to obtain a high-quality welded joint. . The average sheet thickness and aspect ratio of the lamellar secondary α structure were 100 nm and 6:1, respectively. The integral joint with a weld length of 500mm*width of 500mm is used for high temperature superplastic forming with Ar gas. The superplastic temperature used is 900°C, and the gas pressure is 5-20MPa. After forming, a hemispherical component with a diameter of 400mm is obtained. The wall thickness of the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com