Stirring device connecting flange grinding tool and method

A technology of stirring device and tooling, applied in the field of grinding tooling for connecting flanges of stirring device, can solve the problem of sacrificing the verticality accuracy of equipment installation, and achieve the effect of satisfying design intent, improving equipment installation accuracy, and meeting functional requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

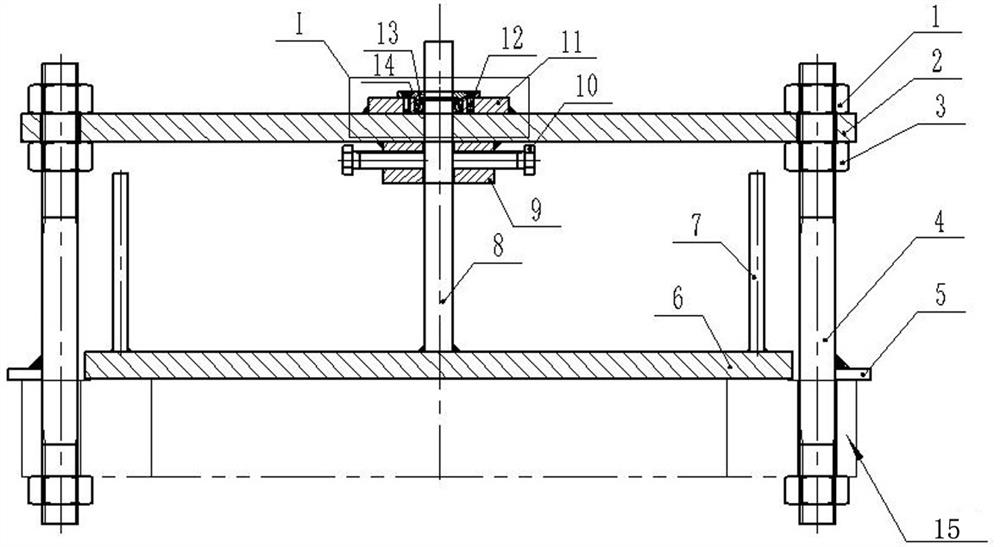

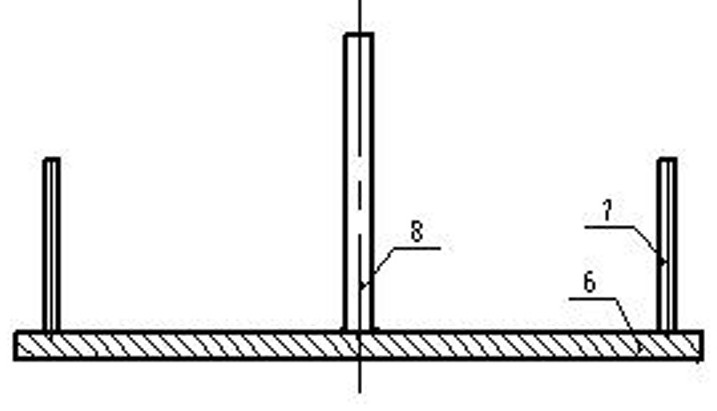

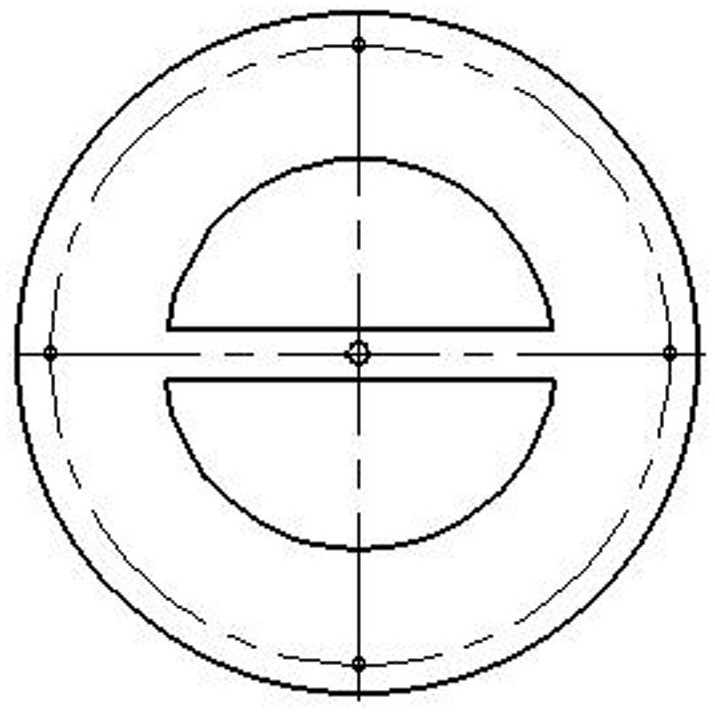

[0029] like Figure 1-6 As shown, a stirring device is connected to a flange grinding tool, including a grinding disc, a support disc and fixed adjustment fasteners. The grinding disc includes a grinding ring 6, and the inner side of the grinding ring 6 is provided with a connecting rib along its radial direction. , the center of the connecting rib plate is fixedly connected with a central axis 8 perpendicular to the grinding ring 6; the support plate includes a supporting ring 2, and the inner side of the supporting ring 2 is provided with a cross-shaped connecting rib plate along its radial direction, and the cross-shaped connecting rib The center of the plate is provided with a central hole for the central shaft 8 to pass through. The central hole is coaxially fixed with a bearing seat 11, and the bottom of the bearing seat 11 is fixed with a locking disc 9. The side of the locking disc 9 The wall is penetrated with threaded holes and screwed with locking bolts 10. Bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com