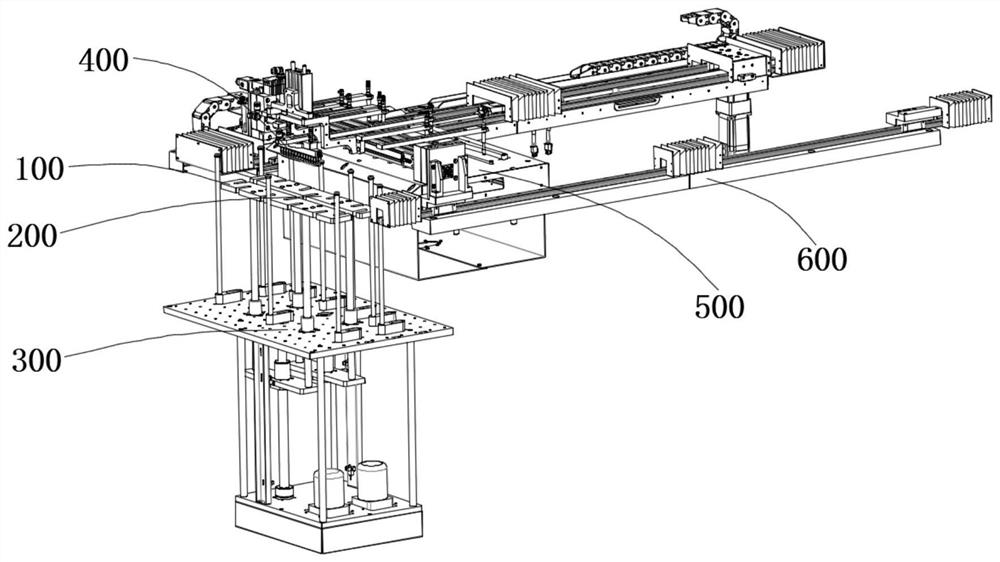

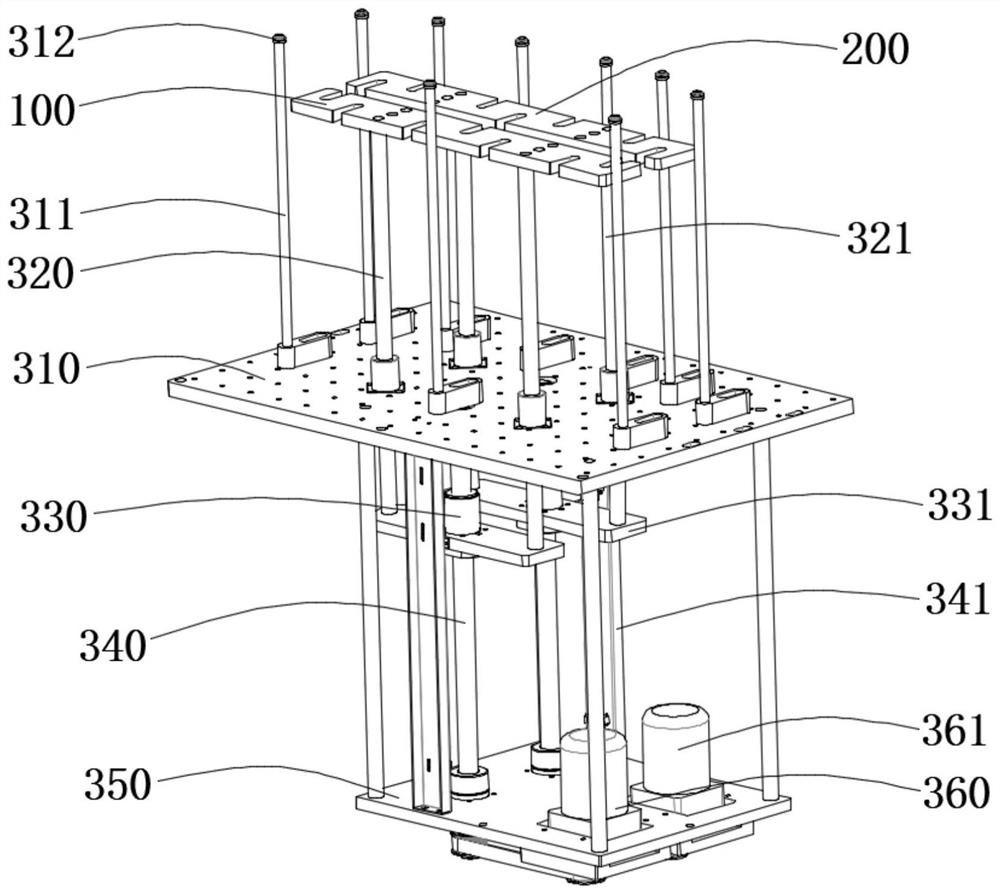

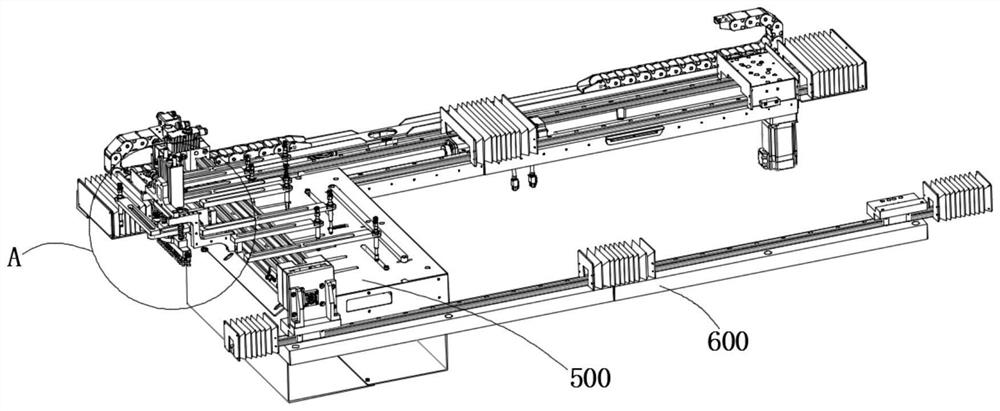

Automatic feeding and positioning device for three-layer combined soft board

An automatic feeding and positioning device technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of low automation efficiency, shedding, and unevenness on the uppermost side of materials, so as to reduce test misjudgments and increase The effect of feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention. It will be appreciated that the specific embodiments described herein are for explaining the invention and is not limited thereto. It will also be noted that in order to facilitate the description, only the parts associated with the present invention are shown in the drawings rather than all structures. Based on the embodiments of the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained without creative labor.

[0029] The "Embodiment" mentioned herein means that the specific features, structures, or characteristics described in connection with the embodiments may be included in at least one embodiment of the invention. This phrase is not necessarily a separate or alternative embodiment of the same embodiment in the various locations in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com