Elastic hook pin device

A technology of hook pin and elastic force, which is applied in the field of elastic hook pin device, can solve the problems of failure of anti-loosening measures, complicated operation, and many bolt connection procedures, and achieve the effect of increasing the amount of loaded materials and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

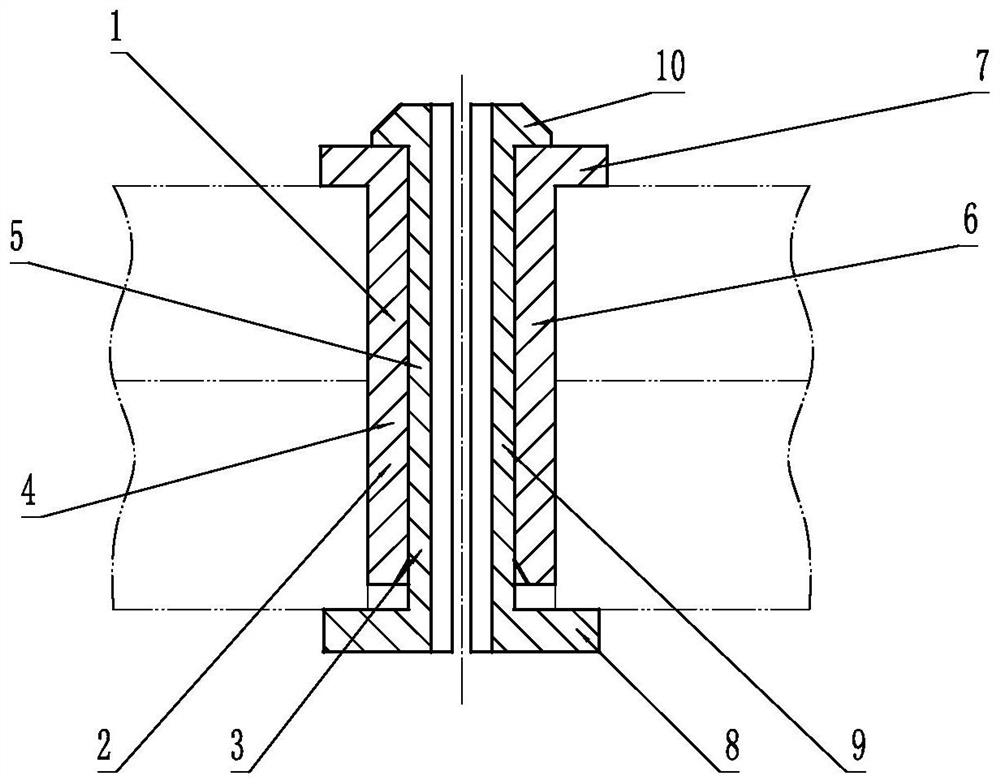

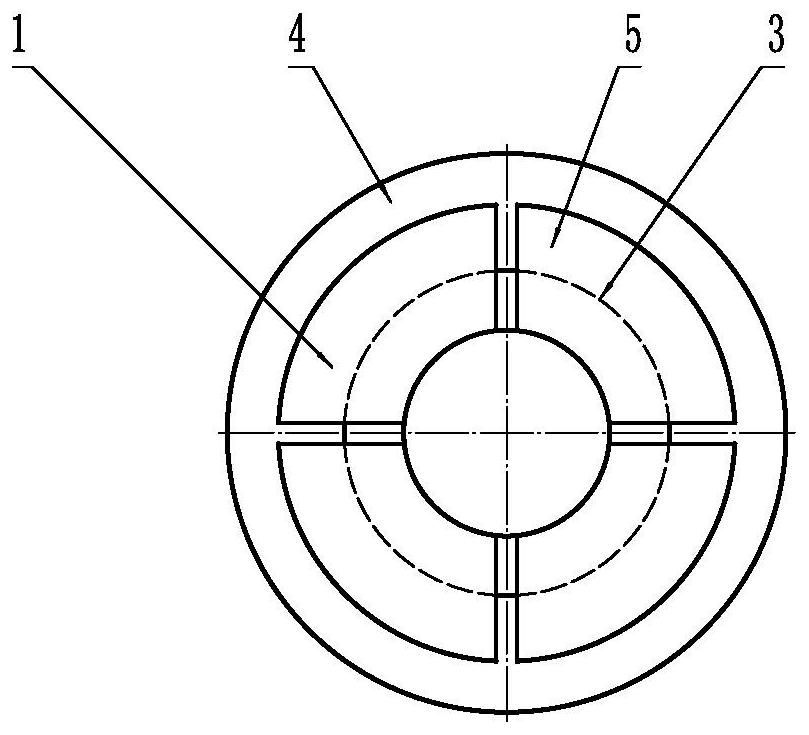

[0039] like Figure 1 to Figure 2 As shown, the elastic hook pin device 1 includes an elastic buckle pin 2, the elastic buckle pin 2 includes an elastic buckle rivet 3, the elastic buckle rivet 3 includes a rivet outer stop tube 4 and an elastic hook pin 5, and the rivet outer stop tube 4 includes The rivet outer cylinder 6 and the rivet outer cylinder stop table 7, the diameter of the rivet outer cylinder 6 is smaller than the rivet outer cylinder withdrawal stop 7, the rivet outer cylinder 6 is arranged on the side of the rivet outer cylinder withdrawal stop 7, and the rivet outer cylinder The cylinder 6 is integrated with the rivet outer cylinder stop table 7, and the elastic hook pin 5 includes the elastic pull nail stop table 8, the elastic pull nail cylinder 9 and the elastic buckle outer cylinder stop table 10. The diameter is larger than the diameter of the elastic rivet barrel 9 and larger than the diameter of the rivet-piercing outer barrel 6, the outer diameter of t...

Embodiment 2

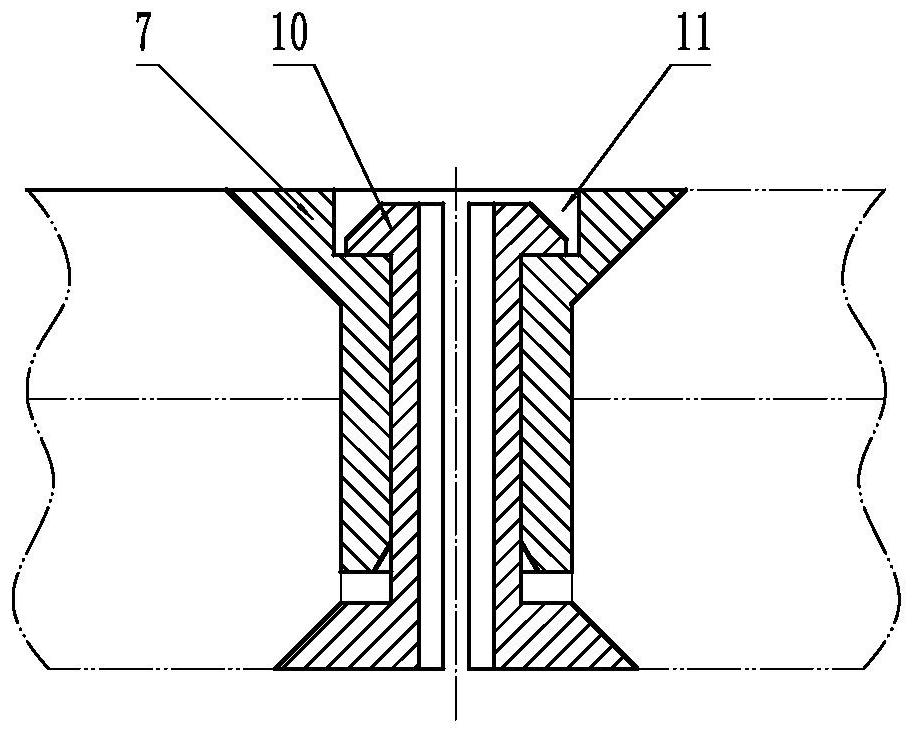

[0042] like image 3 As shown, the rivet outer cylinder backstop 7 is a groove rivet outer cylinder backstop 11, the groove rivet outer tube backstop 11 includes an outer tube backstop groove, and the elastic buckle outer tube backstop 10 is buckled in the concave On the groove rivet outer cylinder backstop platform 7, the elastic buckle outer tube backstop platform 10 is fastened to the outer tube backstop groove, and the outer tube backstop groove protects the elastic buckle outer tube backstop platform 10.

[0043] The rest are the same as in Example 1.

Embodiment 3

[0045] like Figure 4 As shown, the elastic hook pin device 1 includes an elastic hook pin 2, the elastic hook pin 2 includes an elastic hook pin 5, and the elastic hook pin 5 includes a pin shaft stop 12, a pin through the shaft 13 and a pin shaft backstop 14, the pin The diameter of the shaft stopper 12 and the pin shaft retreat stopper 14 is larger than the diameter of the pin through shaft 13. The pin shaft stopper 12 is arranged at the end of the pin through shaft 13, and the pin shaft retreat stopper 14 is arranged at the other end of the pin through shaft 13. The shaft stop 12, the pin penetrating shaft 13 and the pin shaft withdrawal stop 14 are integrated. Under the action of external force, the elastic hook pin 5 is curled inward, so that the pin shaft withdrawal stop 14 passes through the object to be locked 15, and the pin passes through The shaft 13 rebounds and sticks to the object to be locked 15 under the action of its own elastic force; On the other side of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com