Automatic control method and system for powder feeding system

A feeding system, powder technology, applied in the direction of comprehensive factory control, conveying bulk materials, transportation and packaging, etc., can solve problems such as dependence and inability to monitor powder flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

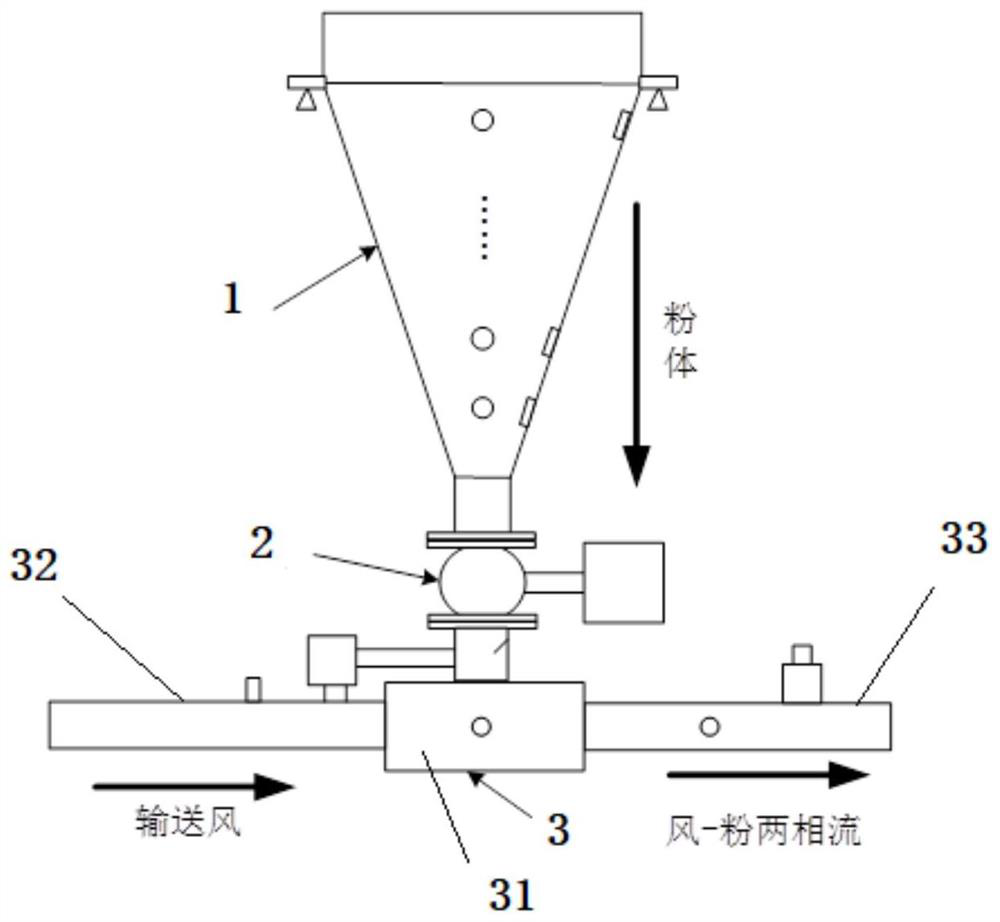

[0070] An embodiment of the present disclosure provides an automatic control method for a powder feeding system, including:

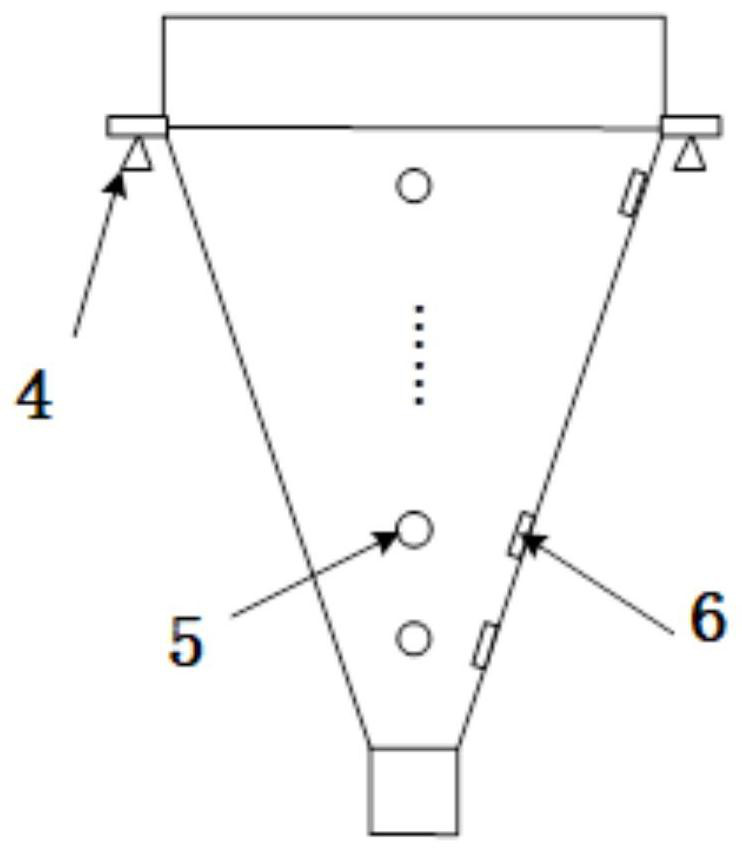

[0071] like figure 2 As shown, the fluidization of powder bin 1 is automatically adjusted,

[0072] Control the operation of the fluidization device 5 arranged on the powder bin 1 according to the obtained powder bin wall pressure;

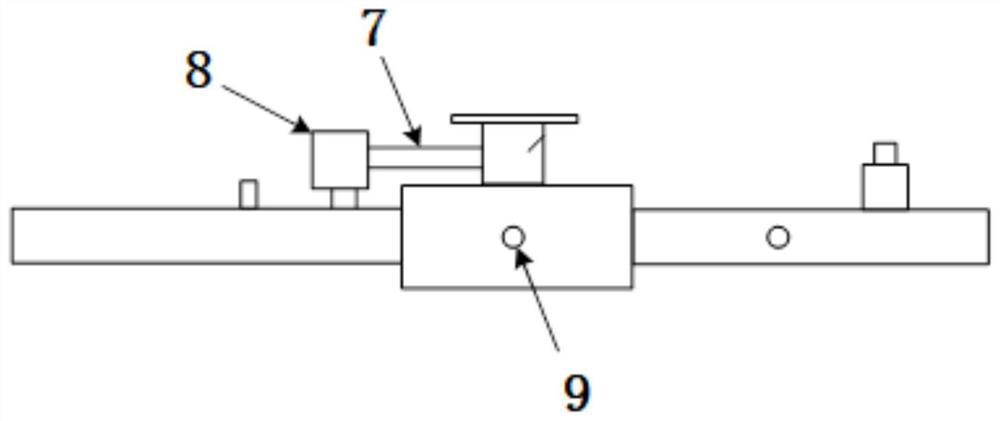

[0073] And / or, carry out automatic adjustment of pressure in the mixer 3,

[0074] According to the average pressure y in the mixing chamber 31 of the mixer 3 and the set quantitative delivery device 2 outlet pressure range [a, b], adjust the connection position from the air phase pipeline 32 and the mixing chamber 31 into the mixing chamber 31 air flow;

[0075] And / or, carry out the automatic adjustment of delivery volume of quantitative delivery equipment 2,

[0076] Determine the optimal powder flow monitoring system on the mixer 3 according to the working frequency of the quantitative conveying device 2, and monit...

Embodiment 2

[0123] Embodiment 1 above provides an automatic control method for a powder feeding system, and correspondingly, this embodiment provides an automatic control system for a powder feeding system. The automatic control system provided in this embodiment can implement the automatic control method of the powder feeding system in Embodiment 1, and the system can be realized by software, hardware or a combination of software and hardware. For example, the system may include integrated or separate functional modules or functional units to execute corresponding steps in the methods of Embodiment 1. Since the evaluation system of this embodiment is basically similar to the method embodiment, the description process of this embodiment is relatively simple, and relevant parts can be referred to part of the description of Embodiment 1. The evaluation system of this embodiment is only schematic.

[0124] An automatic control system for a powder feeding system provided in this embodiment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com