Anti-collision equipment for steering shaft of overhead working truck

A technology for aerial work vehicles and anti-collision equipment, which is applied to lifting devices, building maintenance, building construction, etc., can solve problems such as affecting the normal reception of signals by signal receivers, air-drying and solidification of cement powder, and easy falling of cement powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

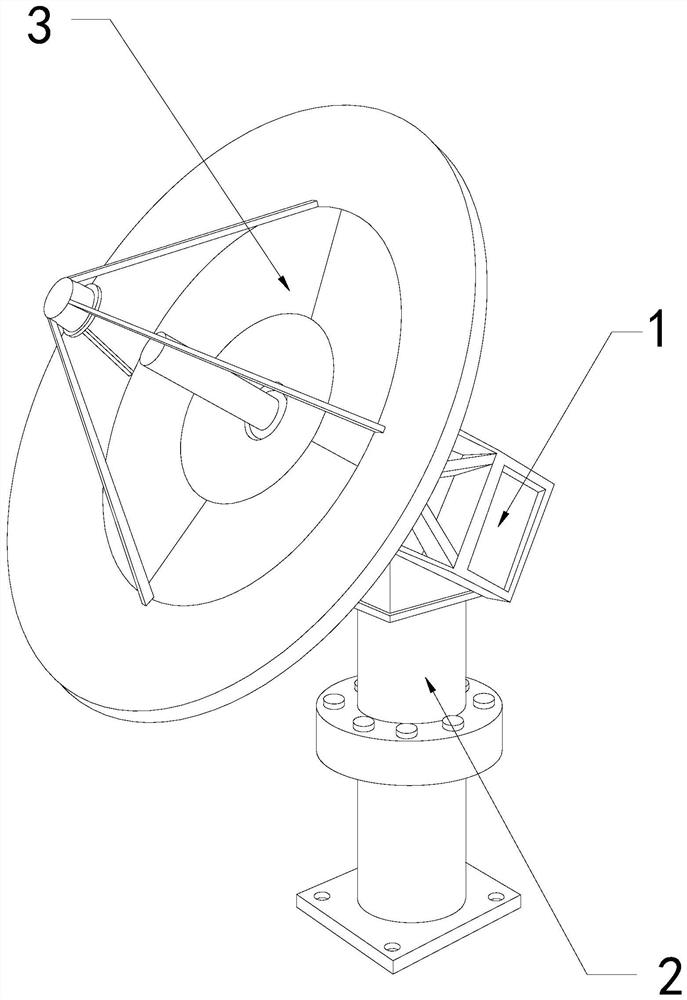

[0026] For example figure 1 -example Figure 5 Shown:

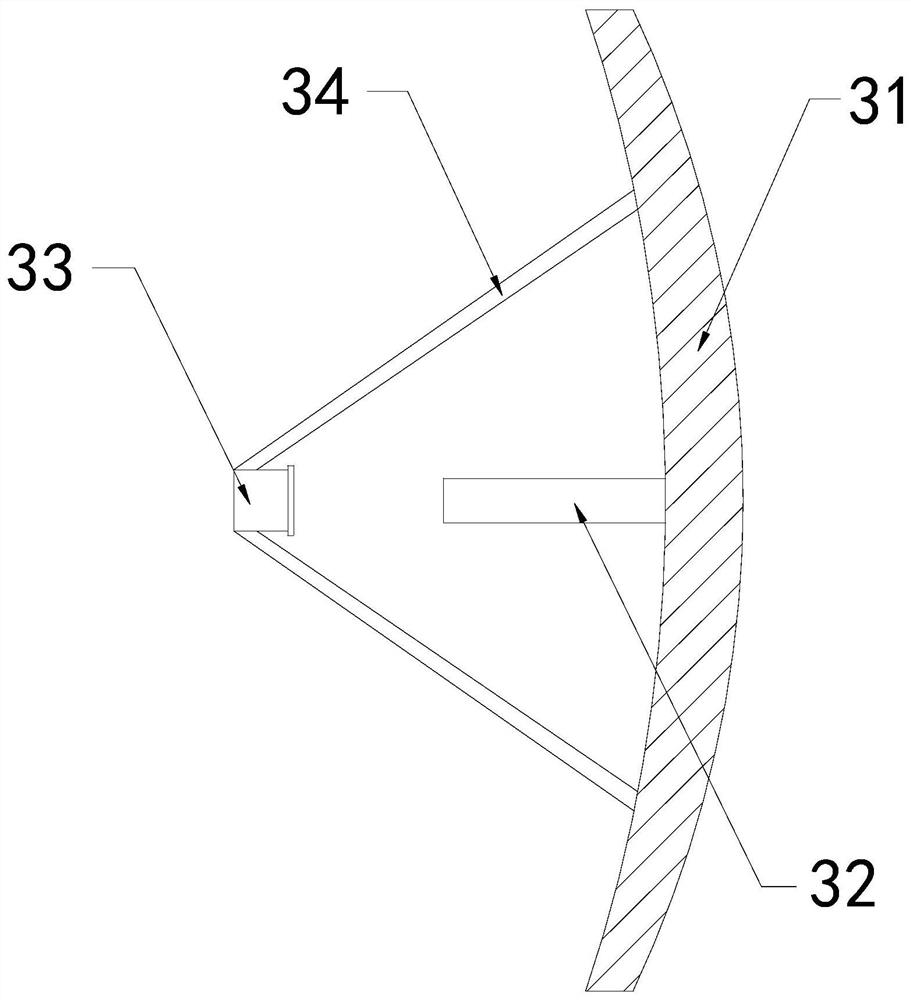

[0027] The invention provides an anti-collision device for the steering shaft of an aerial work vehicle. Its structure includes a steering shaft 1, a support rod 2, and a radar 3. The upper end position of the axis 1; the radar 3 includes a signal booster plate 31, a signal transmitting end 32, a signal receiver 33, and a fixed rod 34, and the signal transmitting end 32 is fixed on the left middle position of the signal booster plate 31, and the The signal receiver 33 is mounted on the inner side of the fixing rod 34 , and the fixing rod 34 is welded to the left side of the signal strengthening board 31 .

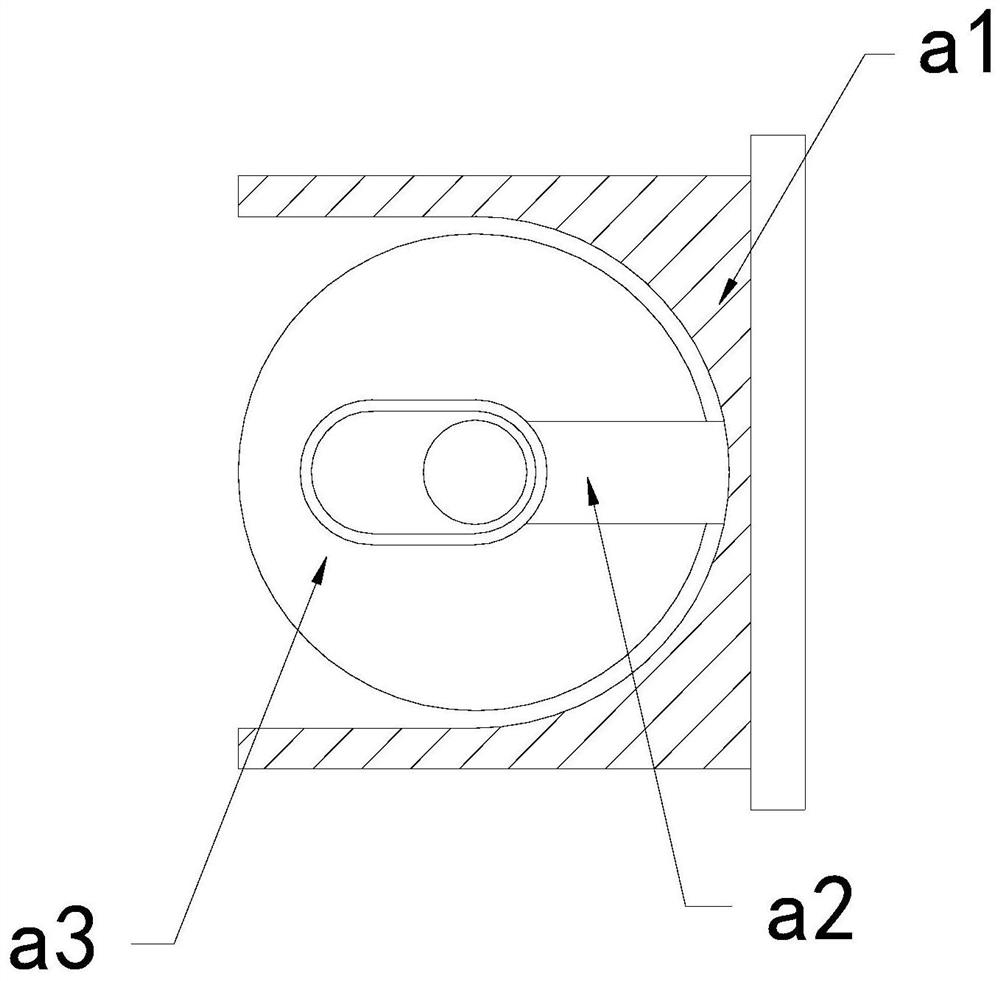

[0028] Wherein, the signal receiver 33 includes an engaging plate a1, a middle connecting rod a2, and a rotating roller a3. The middle connecting rod a2 is fixed on the right side of the inner wall of the engaging plate a1, and the middle part of the rotating roller a3 and the middle The internal sliding fit of the ...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the overhanging plate b1 includes a rear plate b11, an air-drying mechanism b12, an external plate b13, and an absorbing block b14. The air-drying mechanism b12 is embedded in the inner position of the rear plate b11, and the inner side of the external plate b13 Fitted with the outer side of the rear panel b11, the absorbing block b14 runs through the inner position of the outer panel b13, the absorbing block b14 is made of wear-resistant polyether sponge material, and the absorbing block b14 can hold the external panel b13 Moisture on the outside is absorbed.

[0036] Wherein, the air-drying mechanism b12 includes a swing blade c1, a rebound ring c2, and a frame body c3, the swing blade c1 is hinged to the inner side of the frame body c3, and the rebound ring c2 is fixed on the inner side of the frame body c3, There are two swinging blades c1, which are evenly distributed symmetrically inside the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com