Clothes dryer

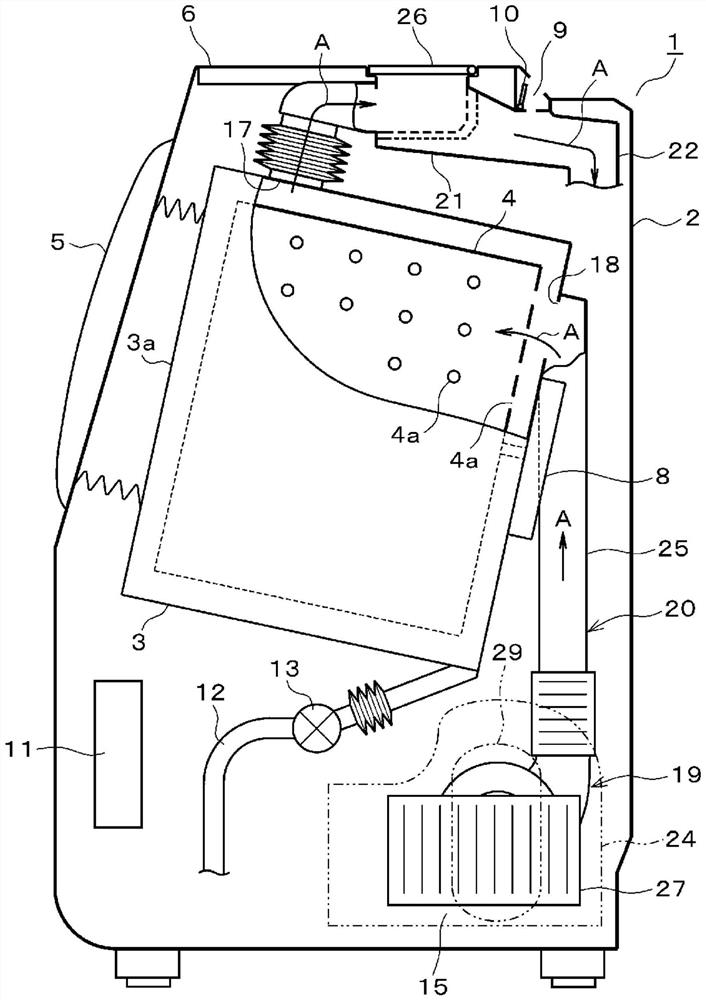

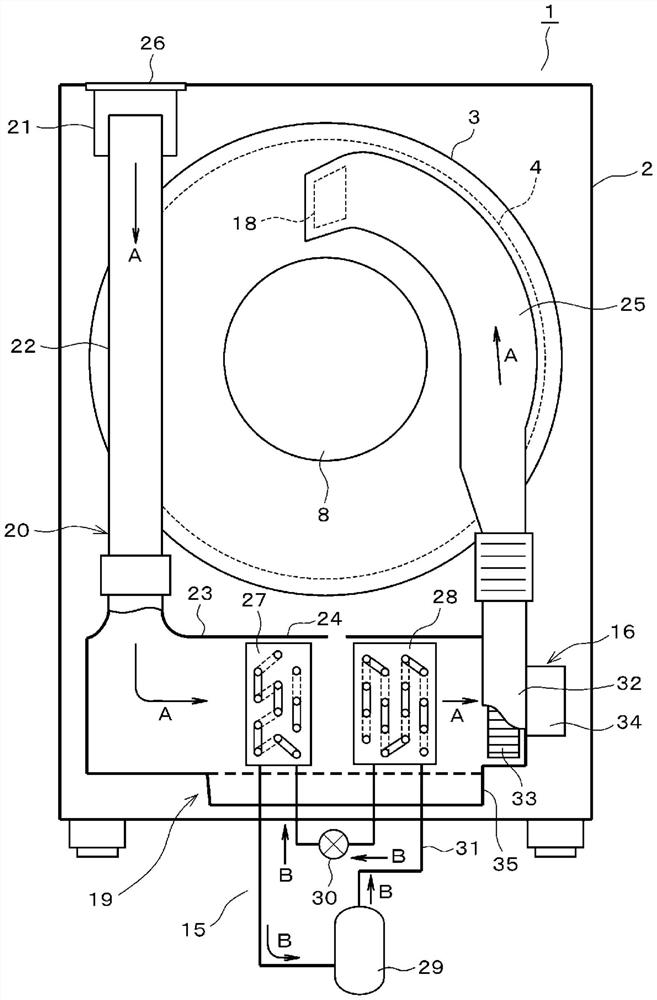

A drying machine and clothing technology, which is used in household dryers, washing devices, textiles and paper making, etc., can solve the problems of shortening drying time, increasing wind speed, and increasing the amount of accumulation in the drainage tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

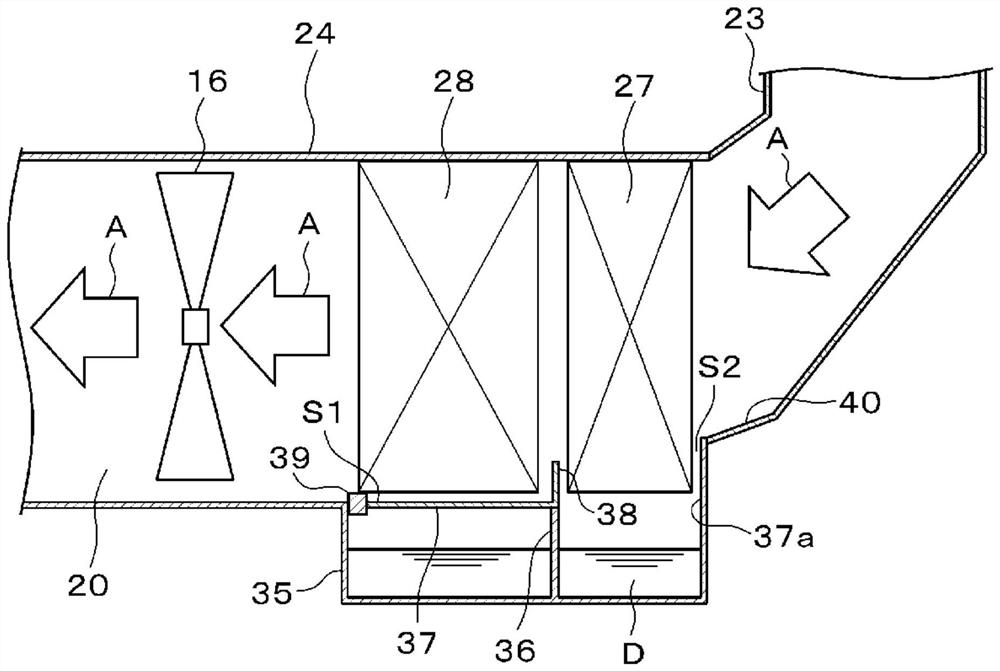

[0055] Figure 4 The second embodiment was shown, and the difference from the above-mentioned first embodiment lies in the configuration of the wind direction plate 42 provided in the evaporator inlet duct 41 constituting a part of the circulation air passage 20 . That is, the evaporator inlet pipe 41 has a quadrangular pipe shape in cross section, and its front end, that is, the left end in the figure extends obliquely downward from the right in the figure, and is connected to the base end of the heat pump pipe 24, that is, the right end in the figure. . At this time, the lower side of the evaporator inlet pipe 41 is connected to the lower side of the heat pump pipe 24 by butting.

[0056] In addition, in the second embodiment, a separate wind direction plate 42 is attached to the bottom wall portion of the front end portion of the evaporator inlet duct 41 to direct the airflow upward. The wind direction plate 42 has a V-shaped cross section and is provided over the entire ...

no. 3 Embodiment approach

[0059] Figure 5 The third embodiment was shown, and the point of difference from the above-mentioned first embodiment is the configuration of the evaporator inlet duct 51 constituting a part of the circulating air duct 20 . That is, the front end portion (left end portion in the drawing) of the evaporator inlet pipe 51 has a rectangular pipe shape in cross section, extends horizontally, and is connected to the heat pump pipe 24 . In this way, the front end portion of the evaporator inlet duct 51 is close to the inlet of the evaporator 27 , and the wind enters the evaporator 27 at a right angle. In addition, the drain tank 35, the tank cover 37, the closing member 39, etc. are provided with the structure equivalent to the said 1st Embodiment.

[0060] According to this configuration, since the front end of the evaporator inlet pipe 51 is close to the inlet of the evaporator 27, the gap S3 between the front end of the bottom wall of the evaporator inlet pipe 51 and the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com