Method for pickling marine product, pickled marine product and pickling solution

A technology for aquatic products and solutions, applied in food preservation, meat/fish preservation, food science, etc., can solve problems affecting the taste and texture of aquatic products, and achieve the purpose of inhibiting the loss of umami, preventing salty taste, and inhibiting dripping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

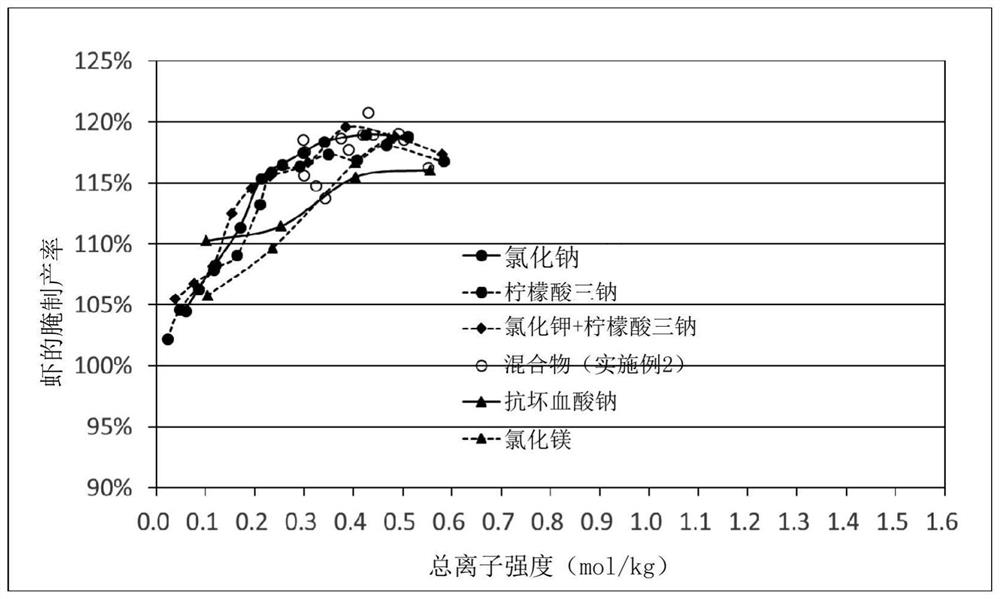

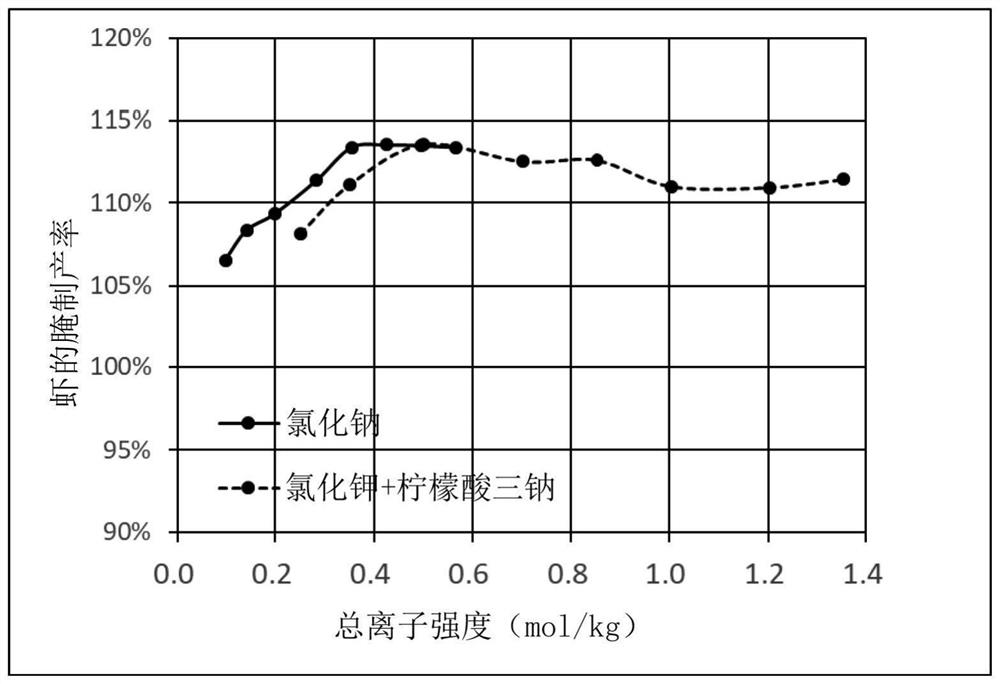

[0110] The ionic strength of the pickling agent

[0111] In order to maintain the productivity of shrimps, pickling with sodium chloride or alkaline agents is carried out in various combinations of different components. A marinade was done with various components in order to find out the most important component and how to use it.

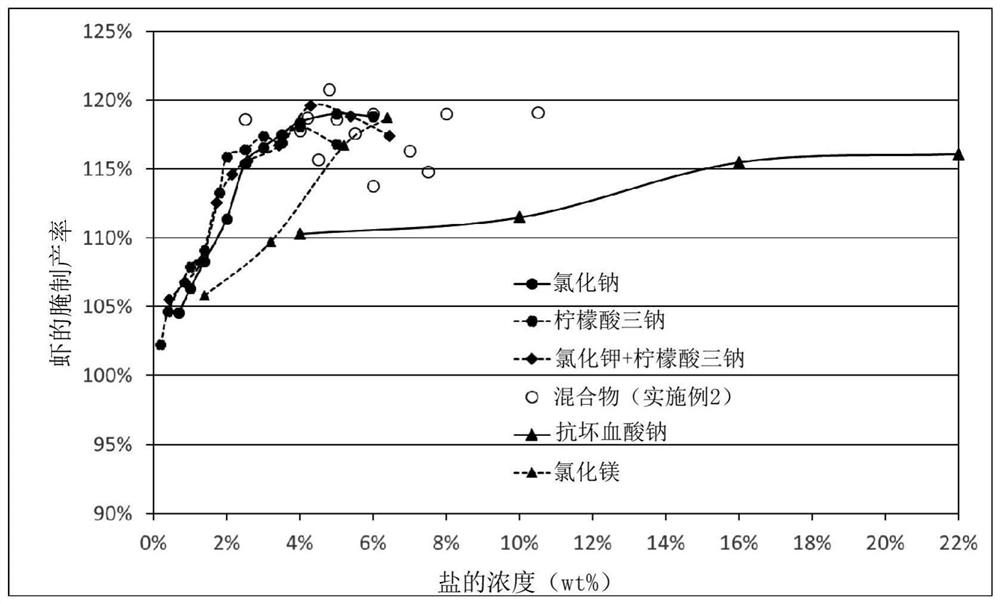

[0112] Sodium chloride, trisodium citrate, potassium chloride+trisodium citrate, sodium ascorbate, magnesium chloride were used as pickling components, and pickling solutions with different concentrations were prepared. Frozen whiteleg shrimp (peeled shrimp) were thawed and pickled for 18 hours using a pickling solution of 100% by weight relative to the weight of the shrimp.

[0113] The results are shown in figure 1 . The results generally show that the yield increases with increasing salt concentration in the pickling solution. However, no indication was obtained as to which ingredients should be used in what ratio when these components are u...

Embodiment 2

[0118] Prepare pickling solutions with 12 recipes shown in Table 1-1 and Table 1-2. Frozen white-legged shrimps (peeled shrimps) were thawed and pickled in a pickling solution of 100% by weight relative to the weight of the shrimps for 18 hours. Comparative Example 1 was not pickled, and Comparative Example 2 used a high pH pickling solution. Heat treatment after pickling: Boil in hot water at 100°C for 90 seconds, then cool with ice water for 1 minute.

[0119] The definitions of "aqueous solution ionic strength" and "total ionic strength" in Table 1-1 and Table 1-2 are the same as in Example 1.

[0120] Measuring the pickling yield, which is the ratio of the weight after pickling to the weight before pickling, and the heating yield, which is the ratio of the weight after heating to the weight before heating , and sensory evaluation of the texture of the shrimp was performed using the heated samples. Based on the evaluation scale of 0 to 2 points, the texture of the shrimp...

Embodiment 3

[0130] Effect of Total Ionic Strength and pH of Aqueous Solution on Yield

[0131] In order to investigate the pH affecting the shrimp-like texture, 6 formulations shown in Table 2 were used to prepare pickling solutions. Frozen white-legged shrimp (peeled shrimp) was thawed and pickled for 18 hours using a 100% by weight pickling solution relative to the weight of the shrimp.

[0132] The definitions of the measurement items in Table 1 are the same as in Example 1, and the sensory evaluation of the heated sample was performed in the same manner as in Example 2.

[0133] The results are shown in Table 2. It was confirmed that when the pH of each pickling solution was 9.5 or higher, the shrimp-like texture was impaired.

[0134] [Table 2]

[0135]

[0136]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com