Charger calibration method, calibration system and charger

A calibration method and technology of calibration system, applied in instruments, measuring electrical variables, measuring devices, etc., can solve the problems of charging effect and safety performance impact of charger equipment, poor applicability of calibration parameters, and single calibration parameter setting, etc. Efficiency and applicability, the effect of improving the accuracy of calibration parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

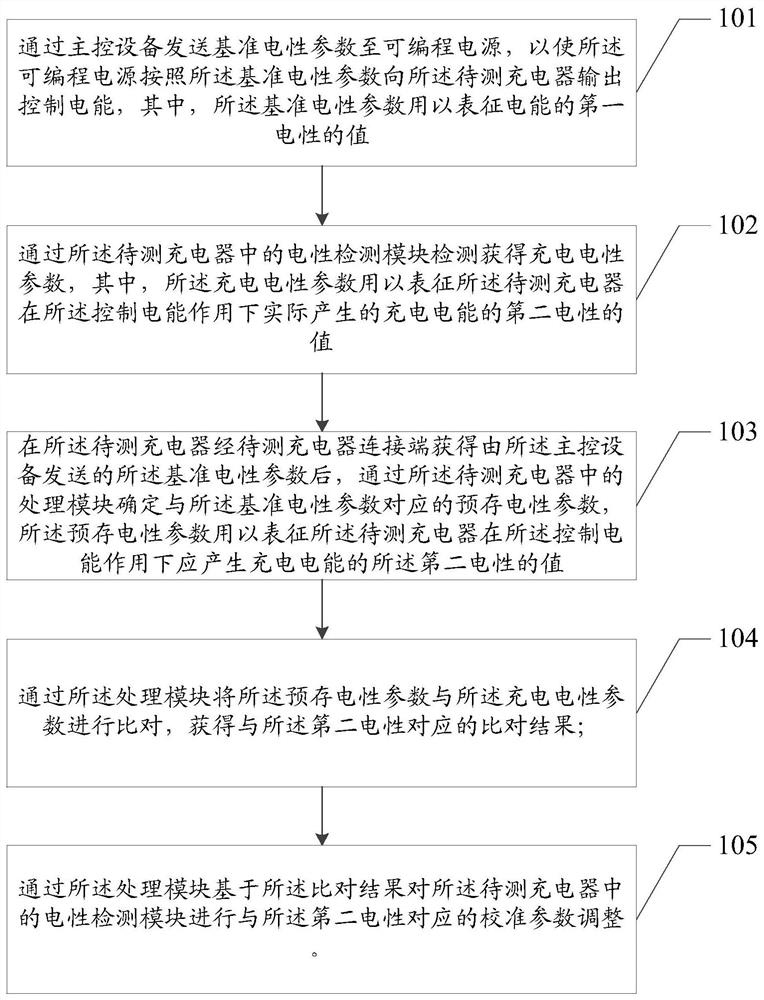

[0055] Please refer to figure 1 , figure 2 , image 3 , Embodiment 1 of the present application provides a charger calibration method, which is applied to the charger to be tested, including:

[0056] Step 101: Send the reference electrical parameters to the programmable power supply through the main control device, so that the programmable power supply can output control electric energy to the charger under test according to the reference electrical parameters, wherein the reference electrical parameters The value of the first electrical property used to characterize electrical energy;

[0057] The first electrical property may refer to any characteristic related to electrical energy, for example, voltage, current, electrical energy mode (AC or DC), cycle (AC), frequency (AC), and so on.

[0058] It can be further understood that the reference electrical property parameter may be a parameter corresponding to a specific first electrical property and characterizing the magn...

Embodiment 2

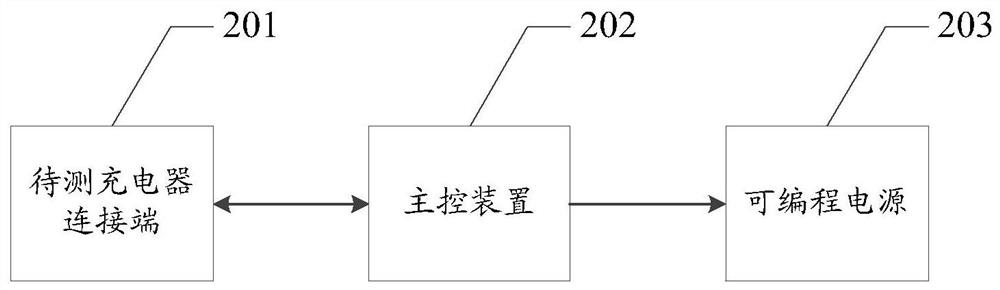

[0085] Please refer to figure 2 , Embodiment 2 of the present application provides a charger calibration system, including:

[0086] The charger connection terminal 201 to be tested is used for connecting the charger to be tested;

[0087] The main control device 202 is connected with the connection terminal of the charger under test and the programmable power supply, and is used to send the reference electrical parameters to the programmable power supply and the charger under test, wherein the reference electrical parameters The parameter is used to characterize the value of the first electric property of electric energy;

[0088] The programmable power supply 203 is connected with the main control device, and includes a power supply output end for electrically connecting with the charger under test, and the programmable power supply is used for charging the under test according to the reference electrical parameters The output of the device controls the electric energy. ...

Embodiment 3

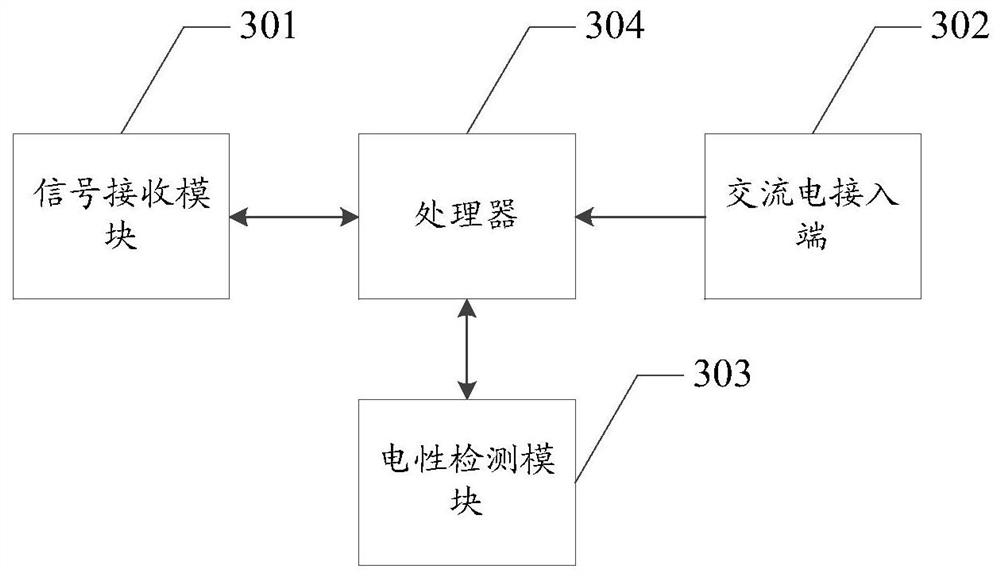

[0099] Please refer to image 3 , Embodiment 3 of the present application provides a charger, including:

[0100] The signal receiving module 301 is used to connect with the connection terminal of the charger under test in the charger calibration system as described in the second embodiment, so as to receive the reference electrical characteristic sent by the main control device in the charger calibration system. parameter;

[0101] The AC power access terminal 302 is used to connect with the power supply output terminal in the charger calibration system as described in the second embodiment, so as to access the control electric energy corresponding to the reference electrical parameter;

[0102] The electrical property detection module 303 is configured to detect and obtain a charging electrical property parameter, wherein the charging electrical property parameter is used to characterize the value of the second electrical property of the charging electrical energy actually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com