A compact vibration-absorbing and heat-dissipating device for a motherboard

A heat dissipation device, a compact technology, applied in instruments, computing, electrical and digital data processing, etc., can solve the problems of small vibration reduction and heat dissipation structure, small space occupation, large space occupation, etc., to solve vibration reduction and heat dissipation, reduce Vibration, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

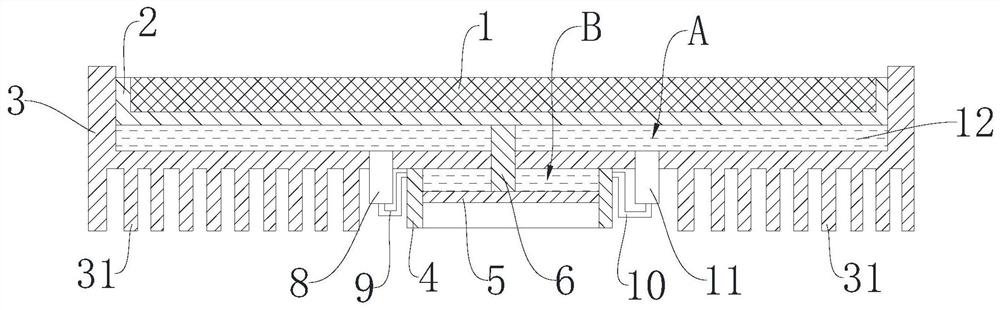

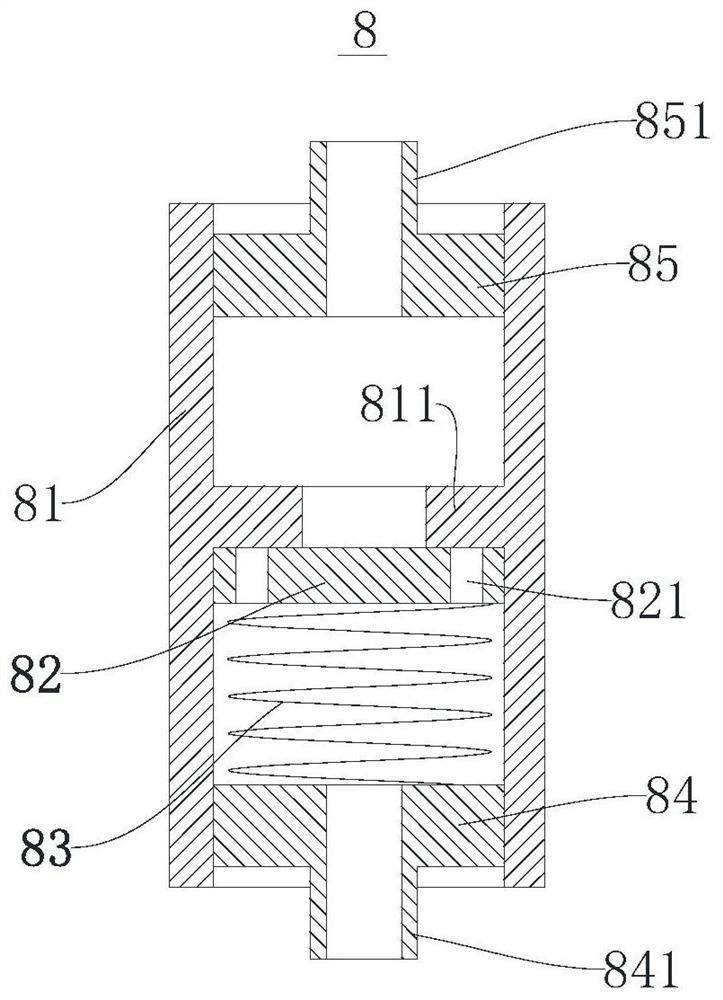

[0023] Example 1: as figure 1 As shown, a compact vibration reduction and heat dissipation device for a mainboard includes an outer base 3 with an upper end opening, an inner base 2 is arranged in the upper end opening of the outer base 3, and the main board 1 is fixed on the inner base 2. A first space A for accommodating the cooling liquid 12 is formed between the bottom of the outer seat body 3 and the bottom of the inner seat body 2, and the outer end surface of the inner seat body 2 is sealed with the inner surface of the outer seat body 3, so that the cooling liquid 12 cannot Leakage from the joint surface can be solved by high-precision coordination at the joint surface. Since the pressure of the coolant 12 is relatively small and the viscosity of the coolant 12 is relatively high, the high-precision coordination can ensure that there is no leakage here; in order to reduce the processing time To ensure the accuracy or to further ensure the sealing effect, a sealing rubb...

Embodiment 2

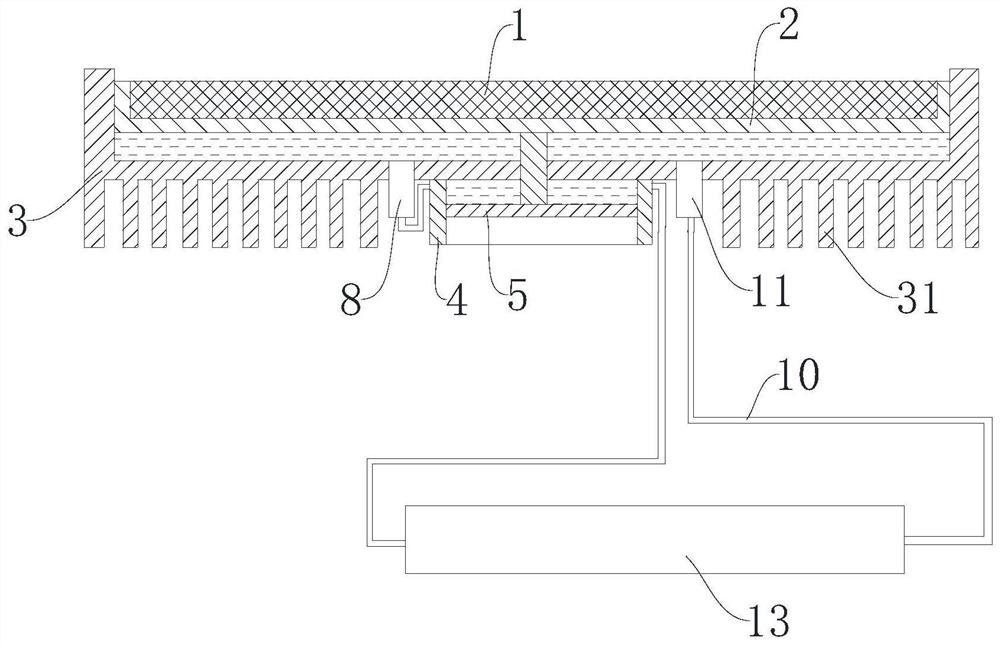

[0027] Embodiment 2: as image 3 , and other structures are the same as those of the first embodiment, except that a cooling chamber 13 is added on the basis of the first embodiment, and the cooling chamber 13 is connected to the first conduit 10 in series. The cooling chamber 13 is generally arranged at a position away from the high temperature parts, and the cooling liquid 12 can obtain better heat dissipation effect when flowing through the cooling chamber 13 . At the same time, the cooling chamber 13 is preferably a deformable flexible soft bag, so that the cooling chamber 13 can be packed and fixed in an irregular space, and there is no need to separately plan the space for placing the cooling chamber 13, so as to make the structure more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com