Humidifier system for fuel cell engine and humidifying method

A fuel cell and humidifier technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems that the amount of water generated cannot meet the inlet air, the inlet air cannot be humidified, and the humidification needs of the stack, etc., to avoid The effects of dry fuel cell stacks, realizing reuse, and alleviating flooding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Apparently, the embodiments described here are only a part of the embodiments of the present invention, and are only used to illustrate the present invention, not to limit the present invention. The technical solutions in the embodiments of the present invention will be described in detail with reference to the drawings in the embodiments of the present invention.

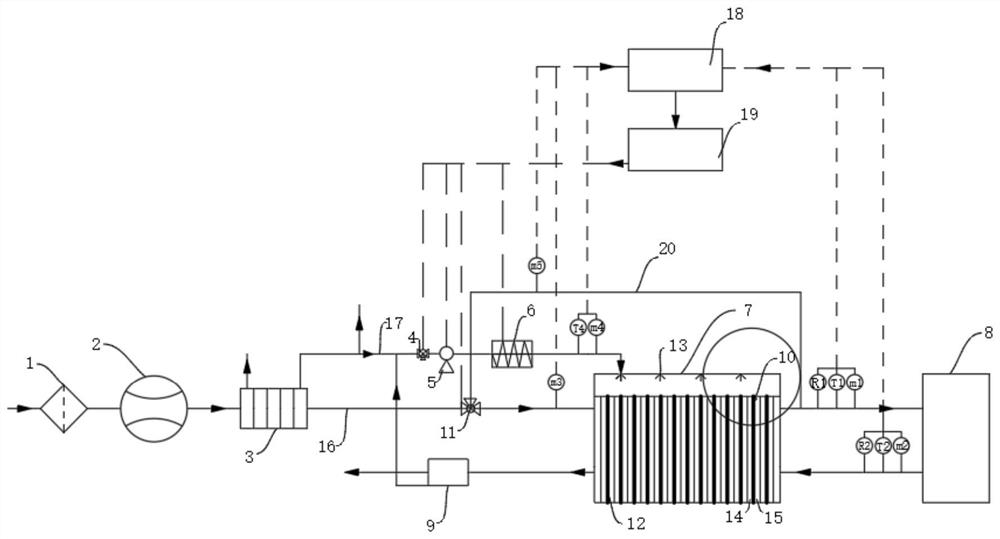

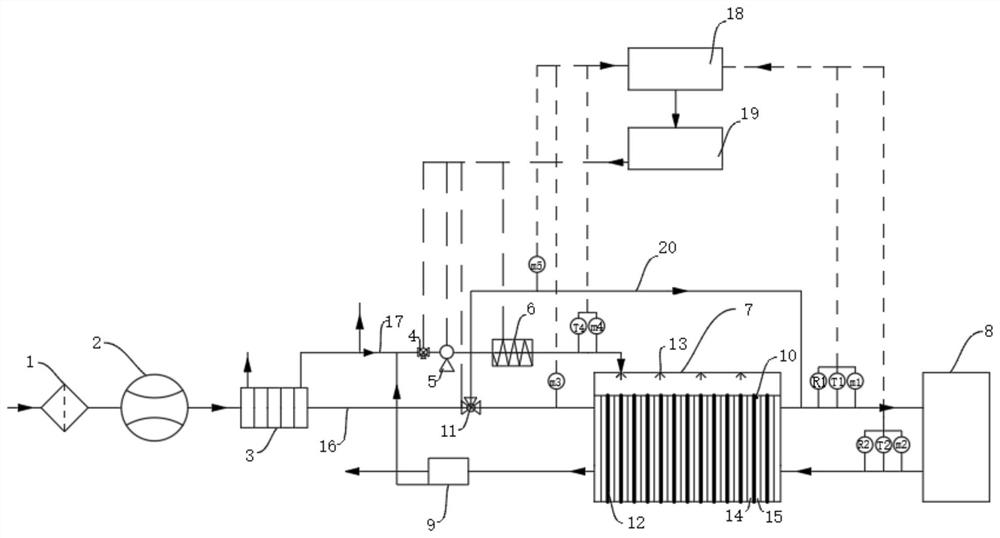

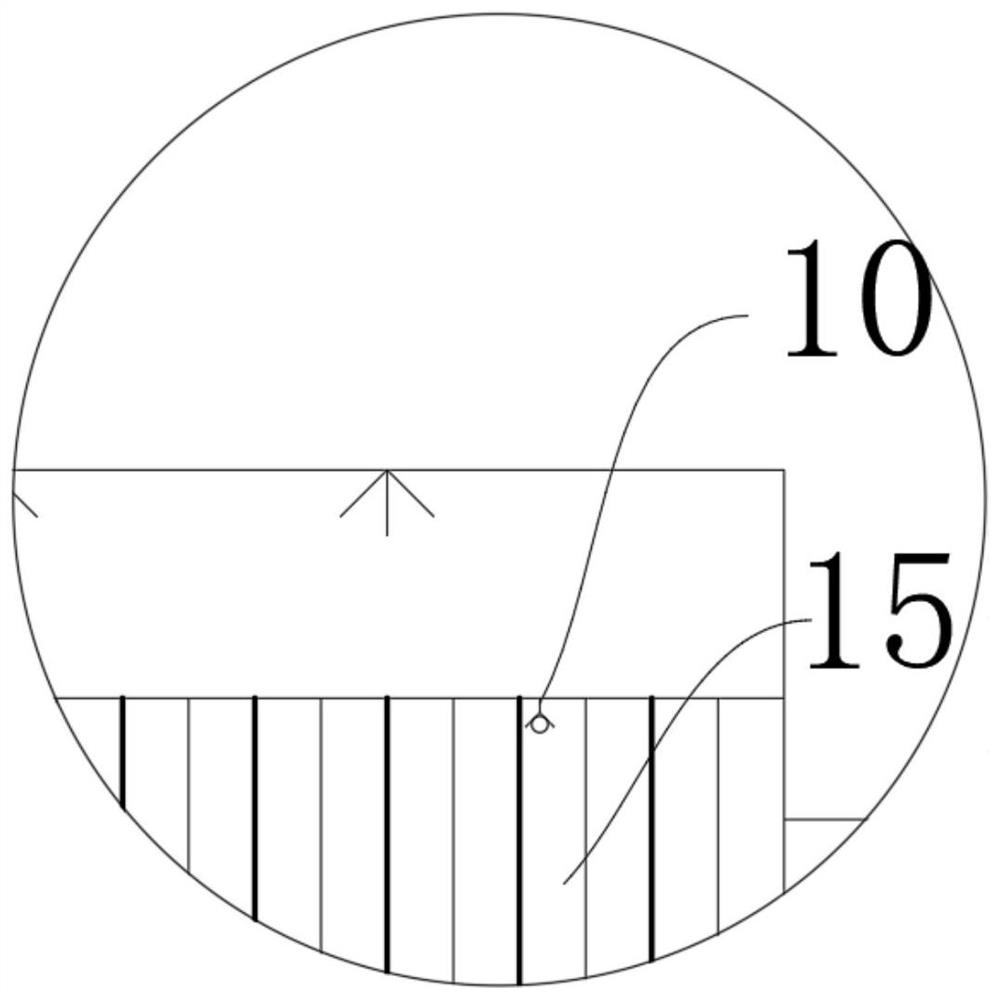

[0035] Such as figure 1 As shown, the present invention is a humidifier system for a fuel cell engine, the main body is a humidifier 7, and the humidifier 7 includes a high-pressure nozzle 13 on the top and dry-side gas arranged at intervals within the spray range of the nozzle below the high-pressure nozzle 13 Flow channel 14 and wet side gas flow channel 15, multi-layer humidification film 12 is arranged at intervals to form several dry side gas flow channels 14 and wet side gas flow channels 15, each dry side gas flow channel 14 and the adjacent wet side The gas channels 15 are separated by a humidificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com