Processing equipment and technology of acid dye for furs

A technology of acid dyes and processing equipment, which is applied to the processing equipment and technology fields of acid dyes for furs, and can solve the problems of layering phenomenon, affecting the mixing effect of dyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

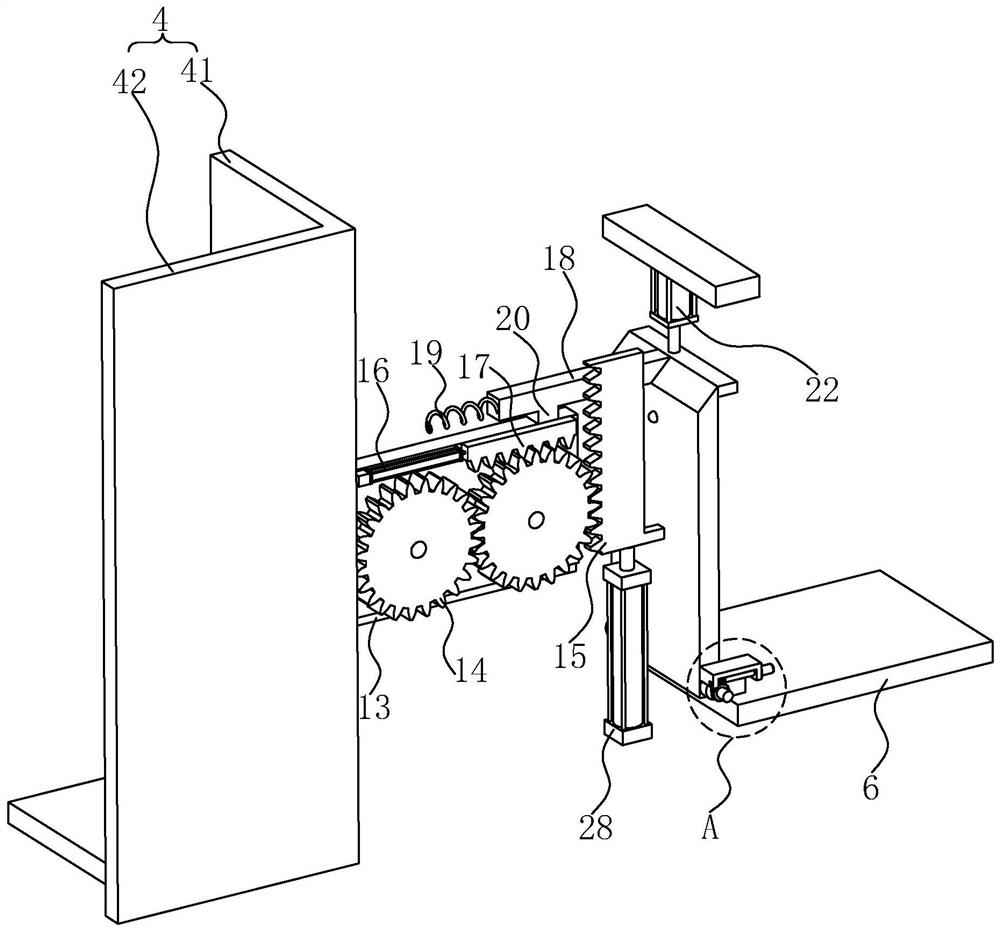

[0043] Attached to the following Figure 1-7This application will be described in further detail.

[0044] The embodiment of the present application discloses a processing equipment of acid dye for fur.

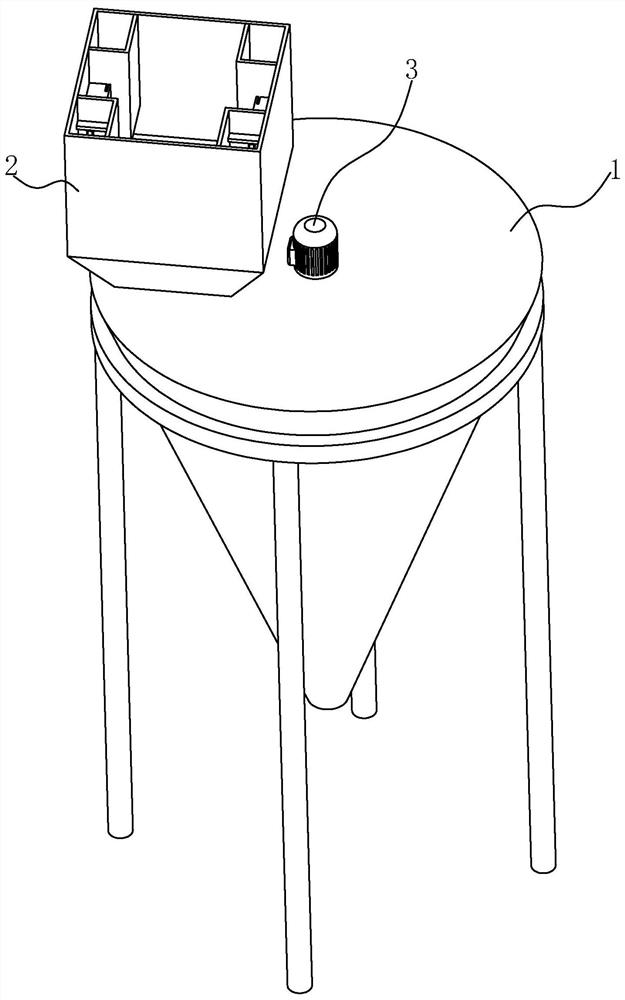

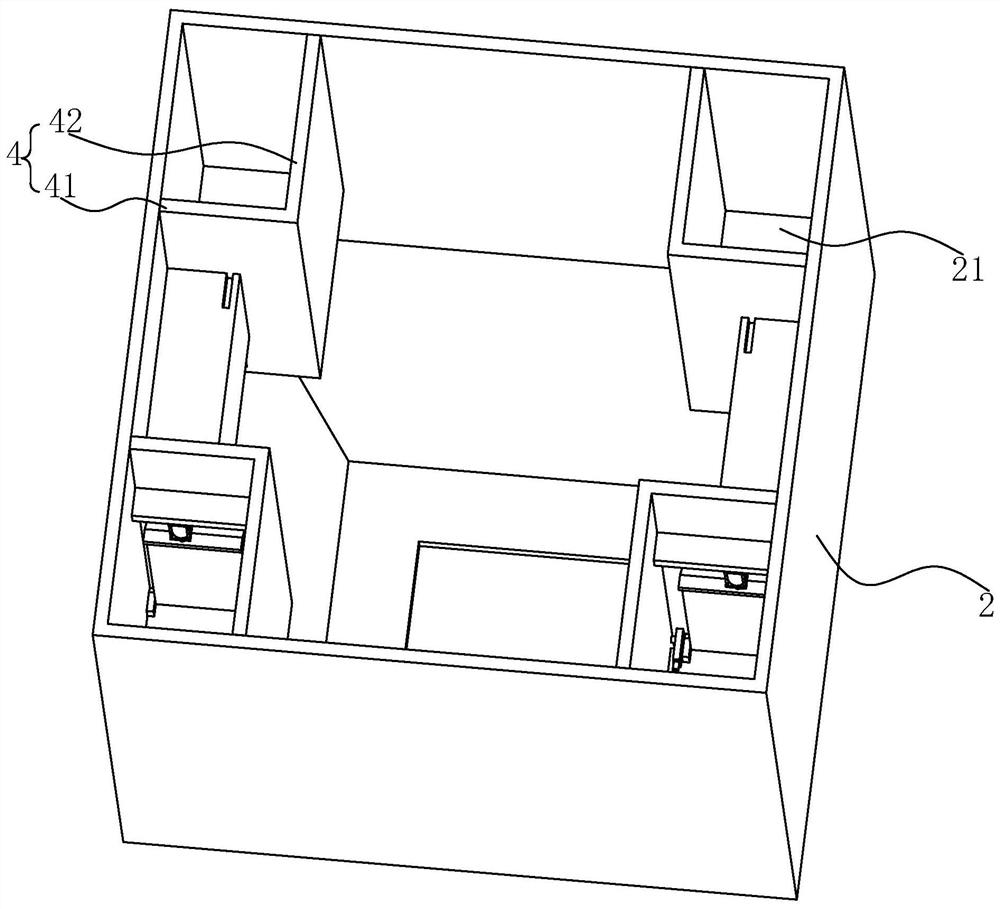

[0045] refer to figure 1 , a processing equipment of acid dyes for furs includes a tank body 1 , and a feeding bin 2 that communicates with the interior of the tank body 1 is fixed on the upper end surface of the tank body 1 . A stirring motor 3 is fixed on the tank body 1 at one end of the feeding bin 2. The output shaft of the stirring motor 3 passes through the upper end face of the tank body 1 and the end of the output shaft is fixed with a stirring shaft for stirring the dye (not shown in the figure). out). Various powder dyes and auxiliary agents are poured into the tank 1 through the feeding bin 2, and the stirring motor 3 drives the stirring shaft to rotate, and the various dyes are fully mixed under the high-speed rotation of the stirring shaft.

[0046] refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com