Cleaning and corrosion-preventing robot for inner wall of variable-diameter pipeline and using method

A robot and pipeline technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as health hazards, avoid hazards, ensure cleaning effects, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

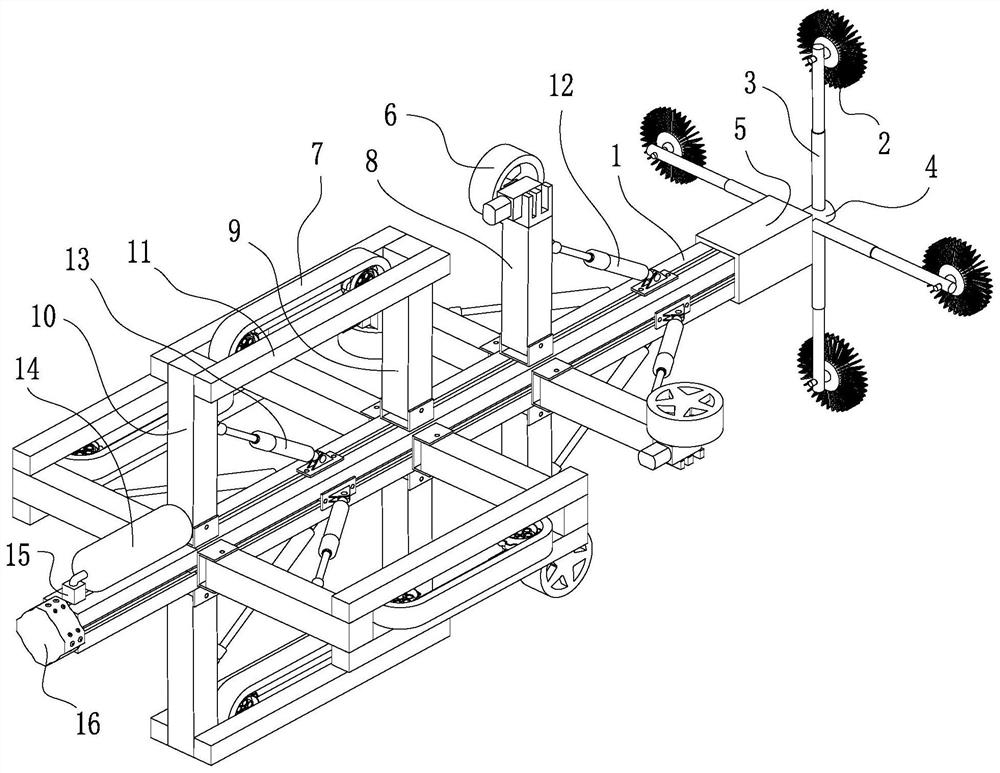

[0022] Such as figure 1 As shown, a variable-diameter pipeline inner wall cleaning and anticorrosion robot includes a central frame 1, a pipeline inner wall cleaning component, a walking component, and a pipeline inner wall anticorrosion liquid spraying component; Components are laid out sequentially on the central rack 1 from front to back.

[0023] The pipeline inner wall cleaning assembly includes a cleaning steel brush 2, a power telescopic rod 3, an adapter fixing sleeve 4 and a cleaning drive motor 5; The frame 1 is coaxially arranged and the motor shaft of the cleaning drive motor 5 faces forward, and the transfer fixing sleeve 4 is fixedly installed on the motor shaft of the cleaning drive motor 5; the bottom end of the power telescopic rod 3 is fixedly connected to the transfer fixing On the cover 4, the cleaning steel brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com