Industrial chemical instrument cleaning equipment

A cleaning equipment and chemical technology, which is applied in the field of industrial chemistry, can solve the problems of external wall damage and affect the reuse of test tubes, and achieve the effect of accelerating cleaning speed and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 6 Shown:

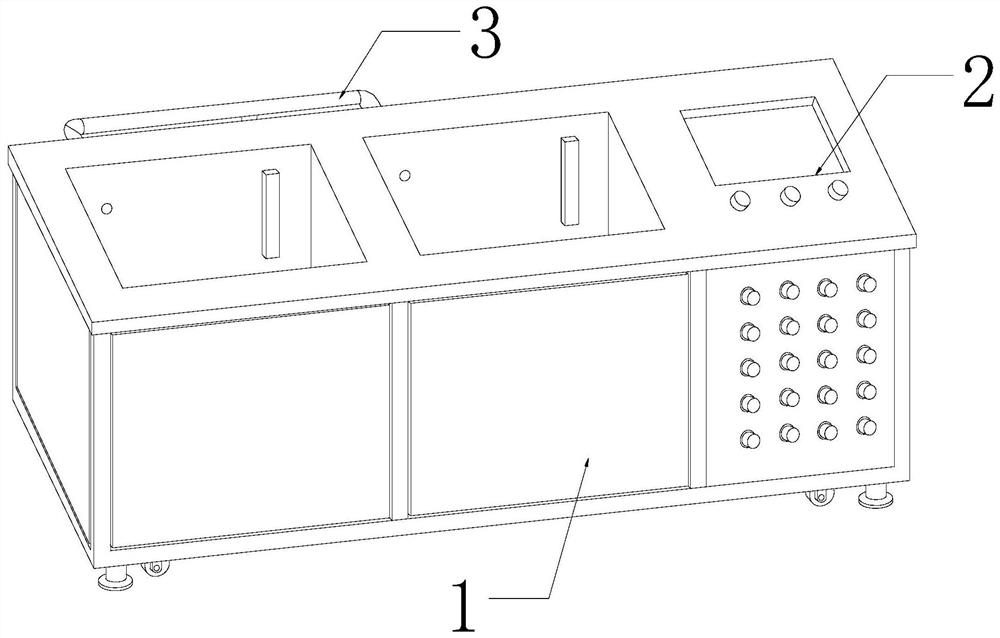

[0028] The present invention provides an instrument cleaning device for industrial chemistry. Its structure includes a body 1, a control panel 2, and a water delivery pipe 3.

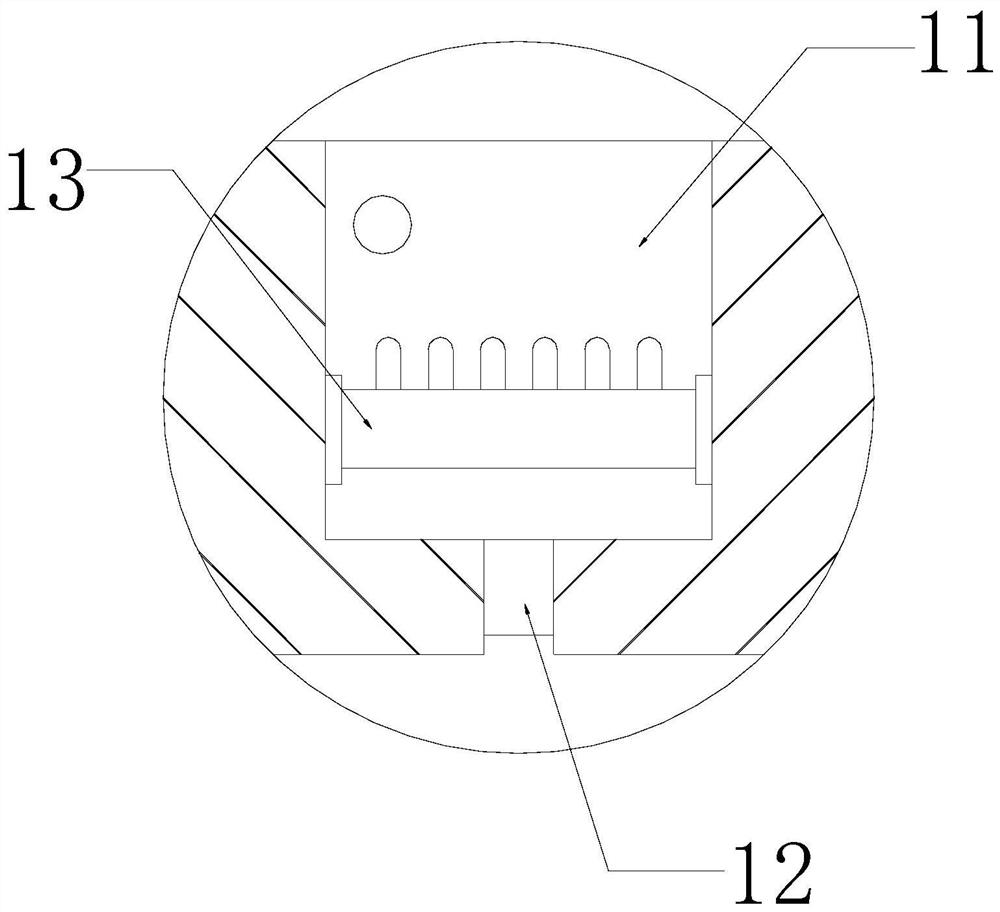

[0029] The body 1 is provided with a cleaning tank 11, a drain port 12, and a limit mechanism 13. The cleaning tank 11 is located inside the body 1, and the drain port 12 runs through the bottom surface of the body 1 and communicates with the cleaning tank 11. The limit mechanism 13 is installed on the inner wall of the cleaning tank 11 .

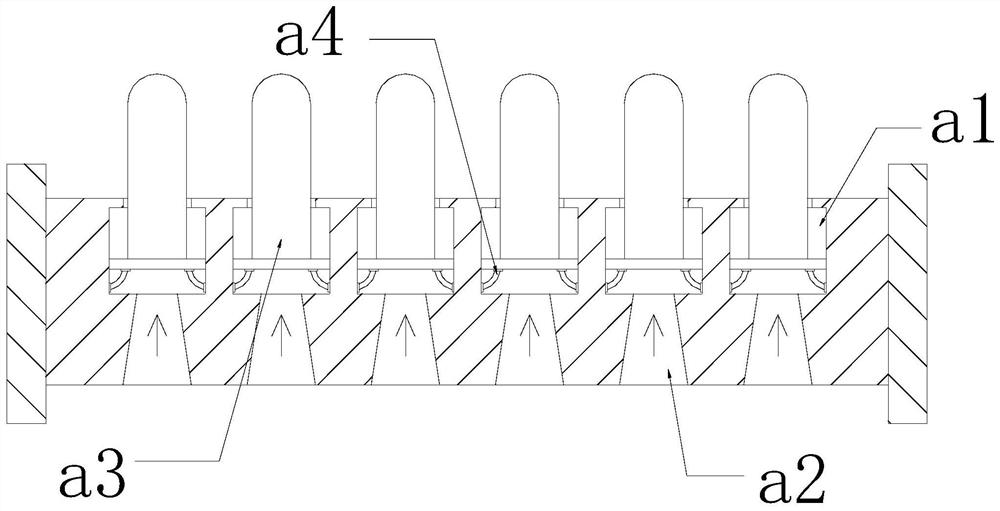

[0030] Wherein, the limit mechanism 13 is provided with an accumulation cavity a1, a water inlet a2, a support pipe a3, and a reset bar a4, the accumulation cavity a1 is set inside the upper middle position of the limit mechanism 13, and the water inlet a2 passes through the limit The bottom surface of the positioning mechanism 13, and communicates with the accumulation chamber a1, the bottom end of the supp...

Embodiment 2

[0037] as attached Figure 7 To attach Figure 8 Shown:

[0038] Wherein, the water inlet a2 is provided with a clamp r1, a connecting shaft r2, and a push rod r3, the bottom end of the clamp r1 is connected to the lower inner wall of the water inlet a2 through the connection shaft r2, and the push rod r3 is horizontally fixed on Between the top side of the clamp r1 and the inner wall of the water inlet a2, there are two clamp r1, which are symmetrically distributed, which is conducive to the cooperation between the clamp r1 and the liquid, and can block the liquid, so that the amount of liquid inside the accumulation chamber a1 change, and the thrust received by the support tube a3 decreases and moves up and down, which is beneficial for the cleaning tube s3 to continuously rub against the inner wall of the test tube and accelerate the cleaning speed of the test tube.

[0039] Wherein, the card board r1 is provided with a board body t1, a magnetic block t2, a connecting blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com