Perforating machine capable of conveniently processing fixed glass plate by using glass

A technology for glass plate and hole punching machine, applied in the field of hole punching machine, can solve the problems of manual adjustment, glass damage, manual positioning, etc., and achieve the effect of convenient hole turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

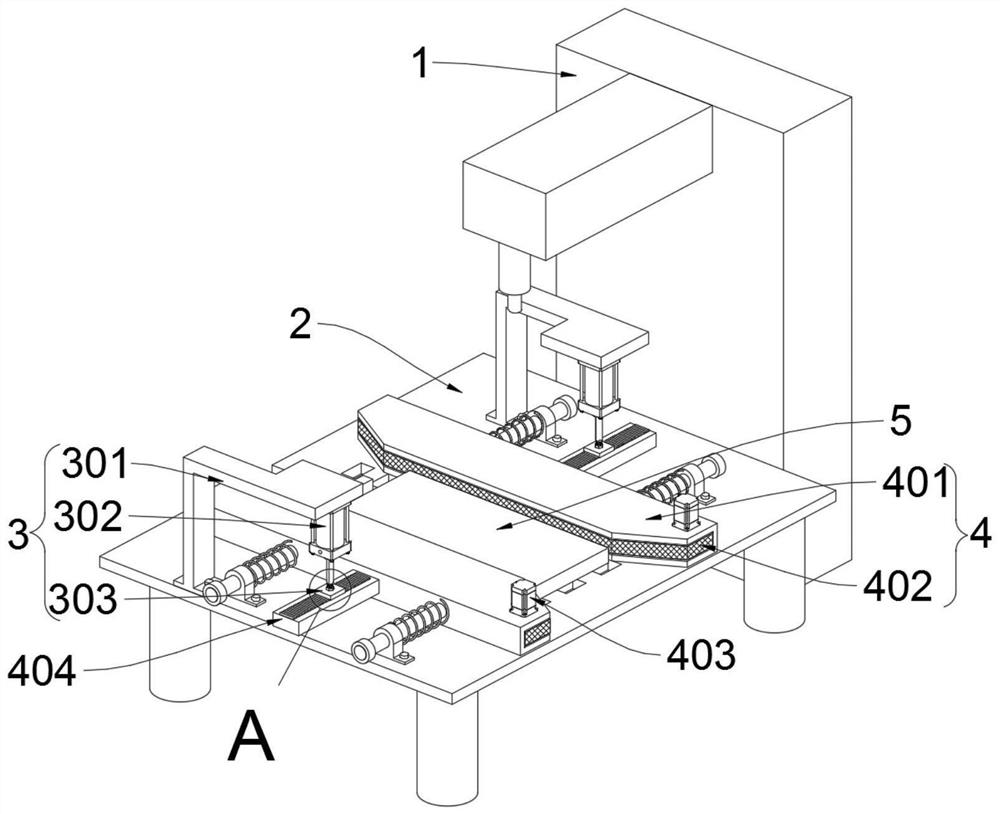

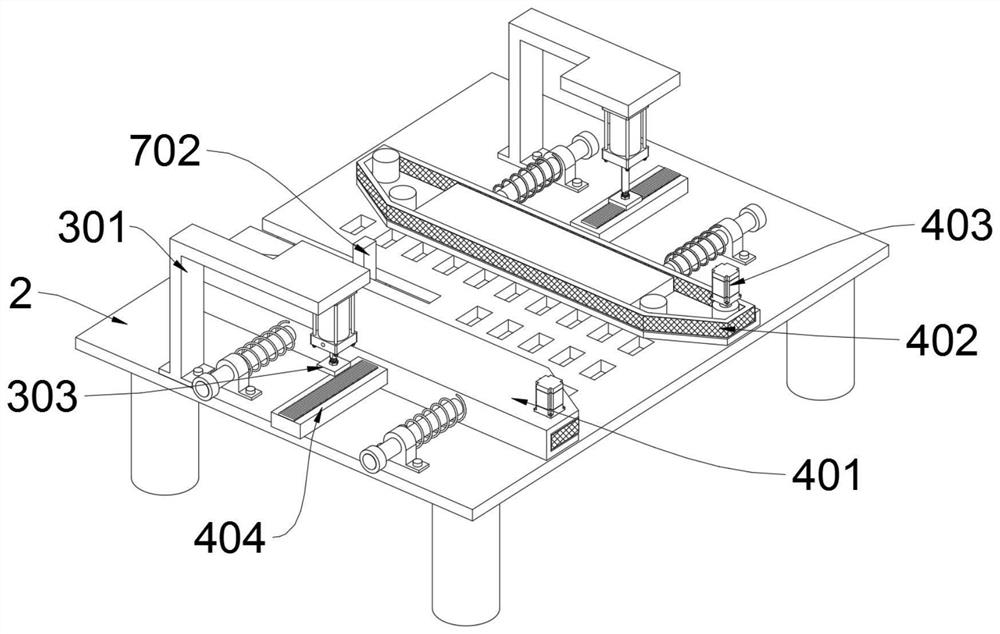

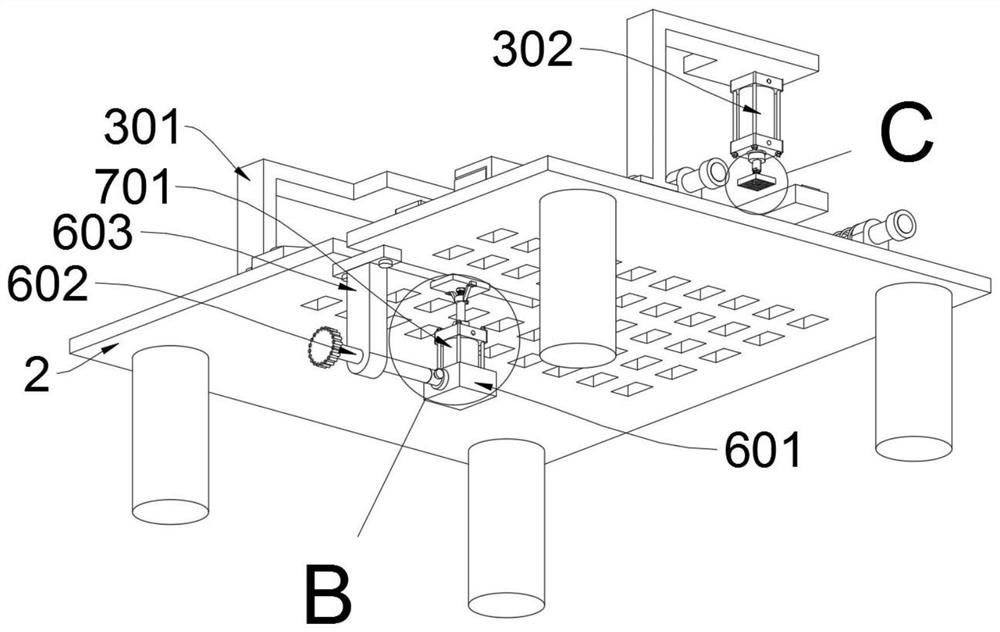

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides a kind of punching machine that is convenient to use glass processing to fix the glass plate, comprises drilling machine 1; A workbench 2 is installed on one side of the driller 1, and a group of supporting legs is installed on the bottom of the workbench 2; Two sets of fixing mechanisms 3 are symmetrically installed on the platform 2, and two sets of slidingly connected transmission structures 4 are symmetrically installed on the workbench 2, and four support seats supporting the transmission structure 4 are symmetrically installed on the workbench 2; the two sets of transmission structures A glass plate 5 is installed between the 4, and a group of distance adjustment mechanism 6 and blocking mechanism 7 are installed on the bottom of the worktable 2, and a reinforcement seat 8 is installed on the blocking mechanism 7; Groove, one side of sliding groove is provided with scale, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com