Efficient quartz sand drying machine

A quartz sand drying and high-efficiency technology, applied in the direction of dryer, drying, dryer combination, etc., can solve the problems of reduced work efficiency, inconvenient dredging, inlet blockage, etc., and achieve the effect of improving work efficiency and convenient dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

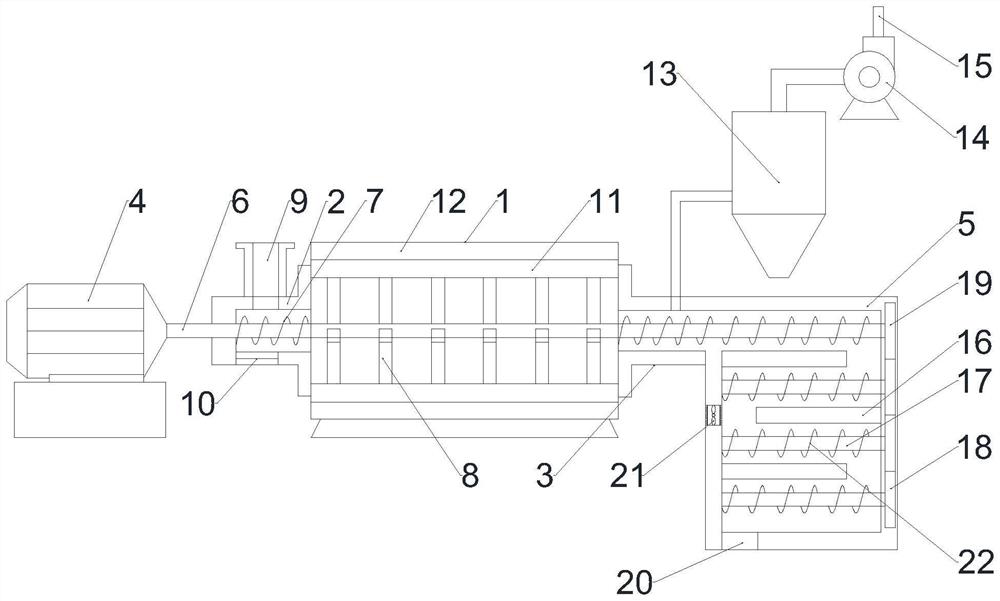

[0020] see figure 1 , the present invention provides a technical solution: a high-efficiency quartz sand dryer, comprising a drying cylinder 1, the left and right ends of the drying cylinder 1 are respectively provided with a feeding cylinder 2 and a discharging cylinder 3, and the other end of the feeding cylinder 2 is provided with a motor 4. The other end of the discharge cylinder 3 is connected to the air drying cylinder 5, the output end of the motor 4 is connected to the main shaft 6, and the main shaft 6 passes through the feeding cylinder 2, the drying cylinder 1, the discharging cylinder 3 and the air drying cylinder 5 in turn, and the main shaft 6 is located in the feeding cylinder. The parts in the drum 2 , the discharging drum 3 and the air drying drum 5 are provided with screw conveying blades 7 , and the part of the main shaft 6 in the drying drum 1 is provided with stirring blades 8 .

Embodiment 2

[0022] see figure 1 , the present invention provides a technical solution: a high-efficiency quartz sand dryer, comprising a drying cylinder 1, the left and right ends of the drying cylinder 1 are respectively provided with a feeding cylinder 2 and a discharging cylinder 3, and the other end of the feeding cylinder 2 is provided with a motor 4. The other end of the discharge cylinder 3 is connected to the air drying cylinder 5, the output end of the motor 4 is connected to the main shaft 6, and the main shaft 6 passes through the feeding cylinder 2, the drying cylinder 1, the discharging cylinder 3 and the air drying cylinder 5 in turn, and the main shaft 6 is located in the feeding cylinder. The parts in the drum 2 , the discharging drum 3 and the air drying drum 5 are provided with screw conveying blades 7 , and the part of the main shaft 6 in the drying drum 1 is provided with stirring blades 8 .

[0023] The upper end of the feeding cylinder 2 is provided with a feeding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com