Self-discharging folding turnover wooden ton box

A technology of wooden ton boxes and discharge valves, which is applied in the field of self-discharging folding turnover wooden ton boxes, can solve the problems of waste of labor and power resources, unclean unloading of material storage, and non-detachable boards, etc., to reduce material transfer Loss and labor and power costs, simplification of installation steps, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure of the present invention is as follows:

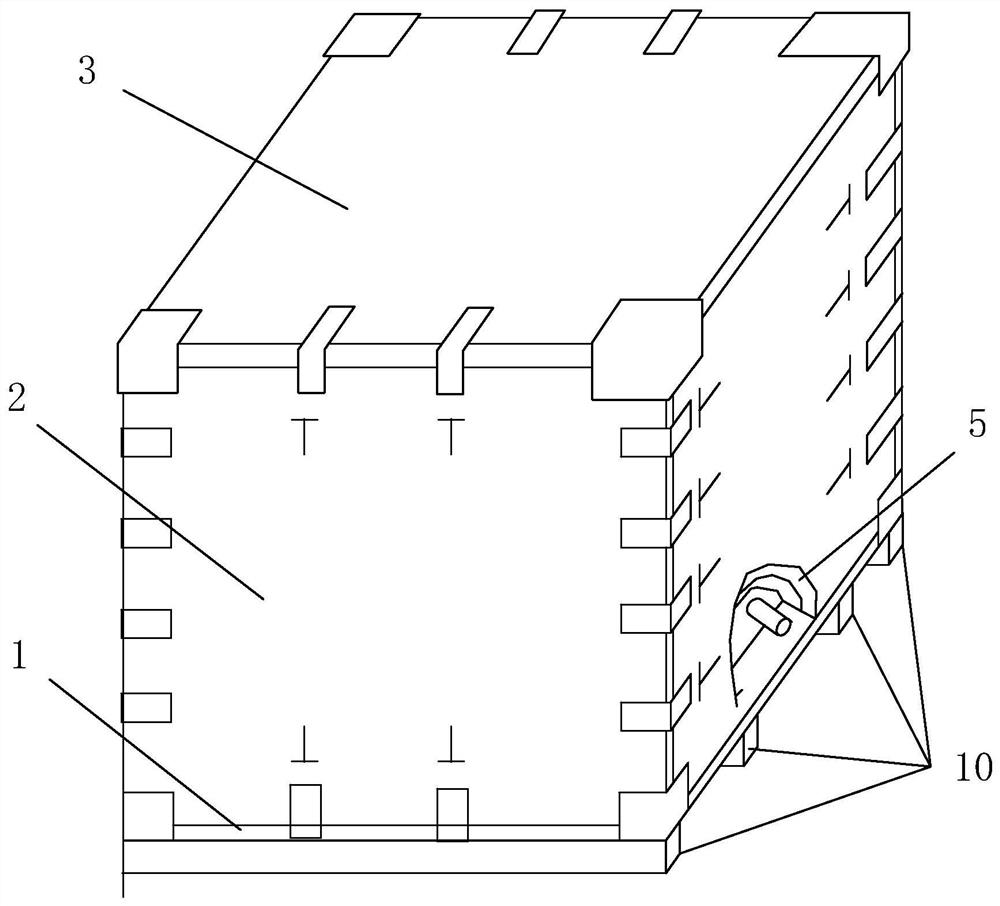

[0027] like figure 1 As shown, a self-discharging folding turnover wooden ton box consists of a lower bottom plate 1, four side plates 2 detachably installed on the lower bottom plate 1, and four side plates 2 detachably installed on the four side plates 2. The upper top plate 3 is composed of; the bottom of the lower bottom plate 1 is installed with crossbeams 10 at intervals, and forklift splines can be accommodated between two adjacent crossbeams 10, and the bottom of any side plate 2 of the wooden ton box is opened. The liquid outlet 5 is provided with a self-discharging device in the liquid outlet 5 .

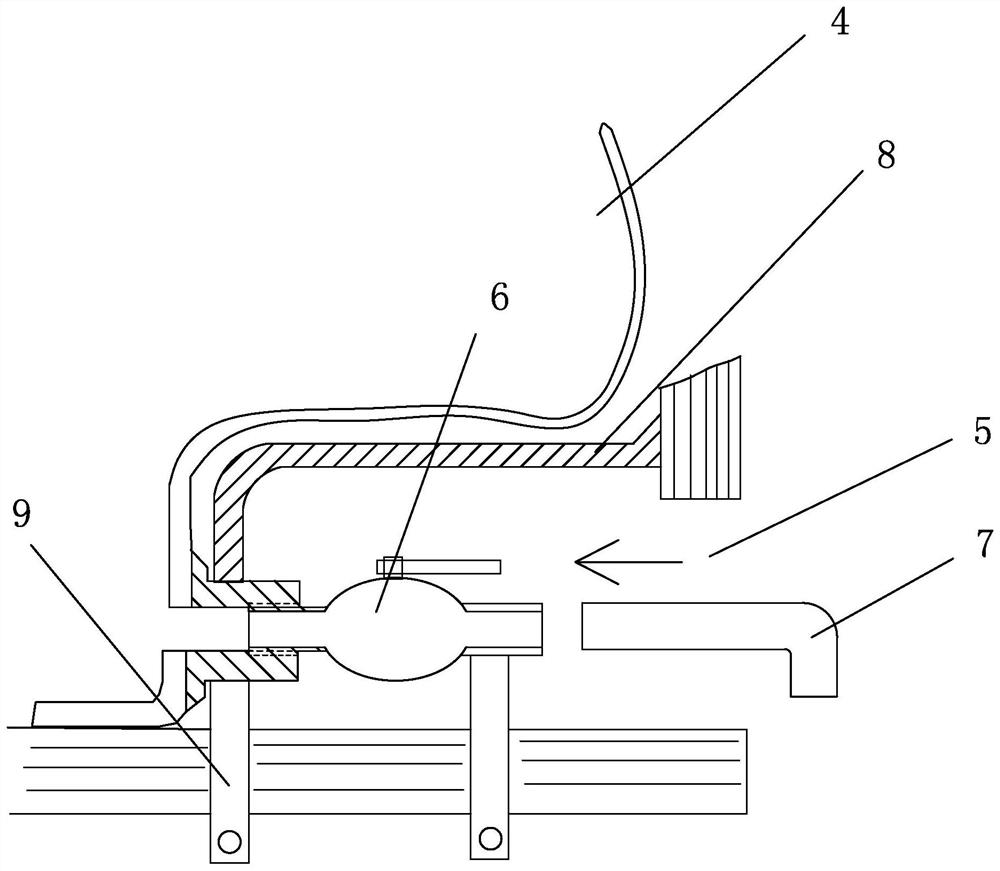

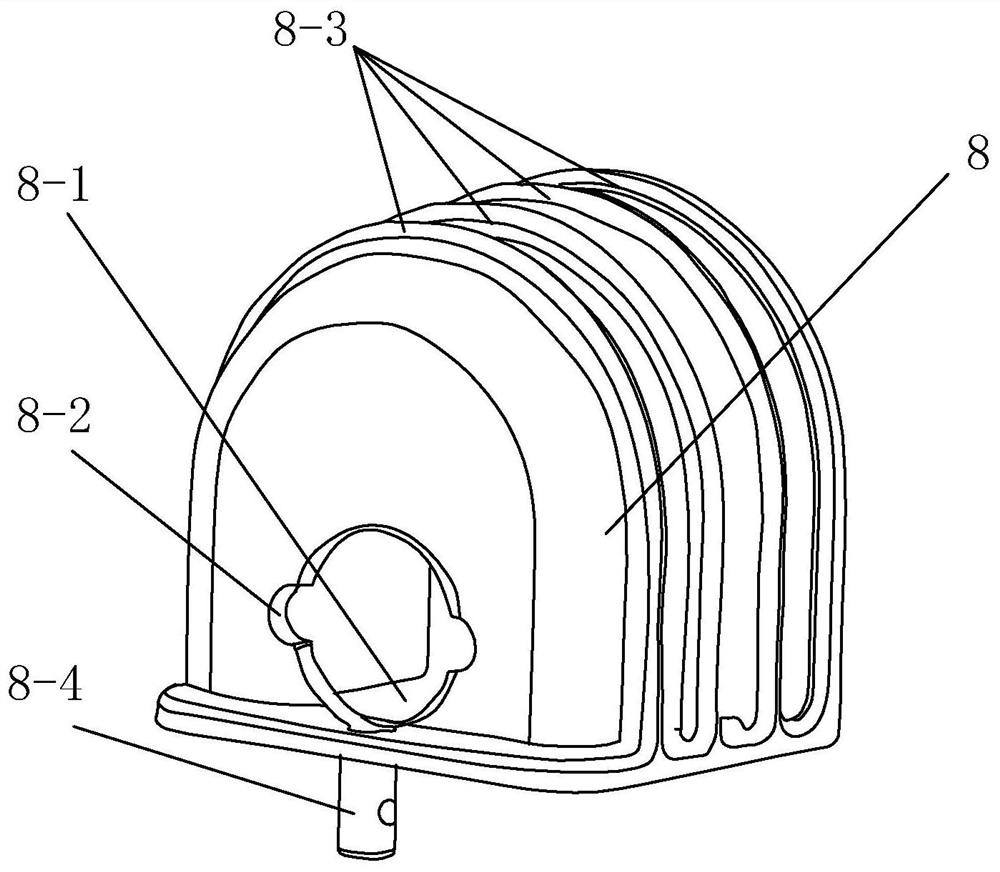

[0028] like figure 2 As shown, the self-discharging device includes a discharge valve cover 8 with a side opening abutting against the inner edge of the discharge port 5, and a discharge valve 6 arranged in the discharge valve cover 8; The abutting position between the side opening of the discharge valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com