Coke oven coal tower coal nozzle control system and method

A control system and coal nozzle technology, which is applied in the field of the coal nozzle control system of a coke oven coal tower, can solve the problem of affecting the production plan and output, the inability to accurately make the coal replenishment plan, and the inability to understand the coal receiving plan and the coal receiving plan of the stoker car. The actual situation and other problems, to achieve the effect of reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

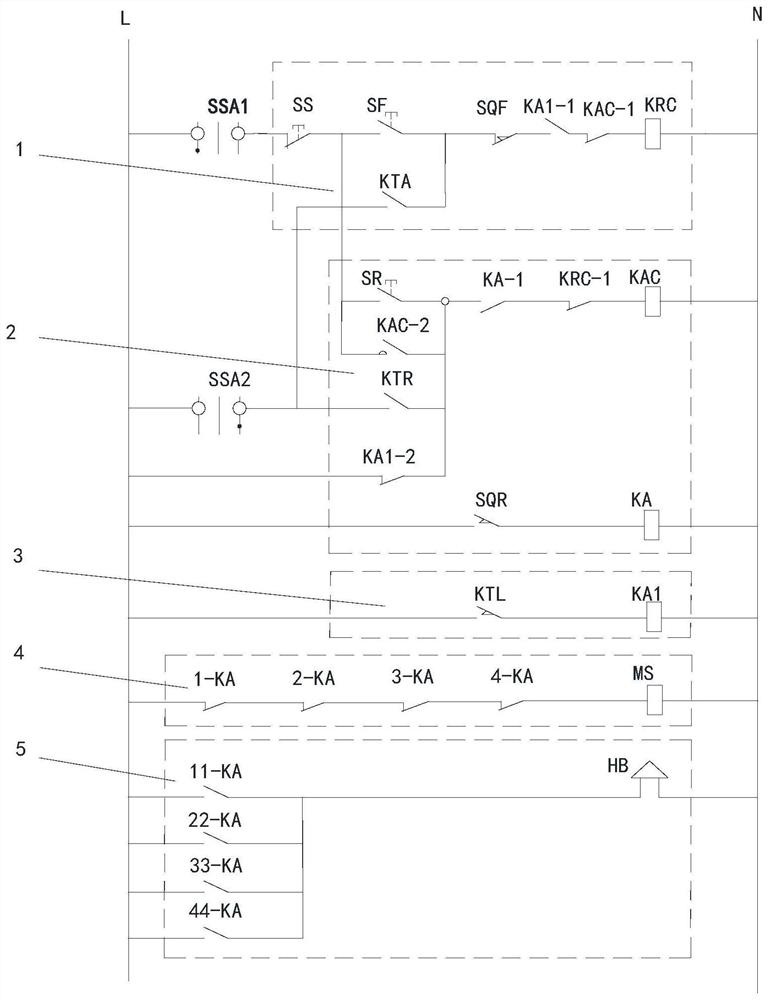

[0036] Such as figure 1 As shown, a coke oven coal tower coal nozzle control system includes a coal nozzle control open circuit 1 connected between the live line and the neutral line, a coal nozzle control closed circuit 2, a coal nozzle control alignment interlock circuit 3, and a coal nozzle control loop 3. Mouth closed and interlocked coal loading running unit 4, control coal nozzle is not closed tightly alarm unit 5;

[0037] In practice, the coal nozzle control open circuit 1 is provided with two branches, wherein the first branch is connected with the live wire and the neutral wire; the second branch is connected with the live wire and the coal nozzle control closed circuit.

[0038] The first branch is sequentially connected with selector switch SSA1, stop button SS, open button SF, coal nozzle open limit SQF, KA1 normally open auxiliary point KA1-1, coal nozzle close contactor KAC normally closed auxiliary point KAC- 1. Coal nozzle opening contactor KRC;

[0039] One...

Embodiment 2

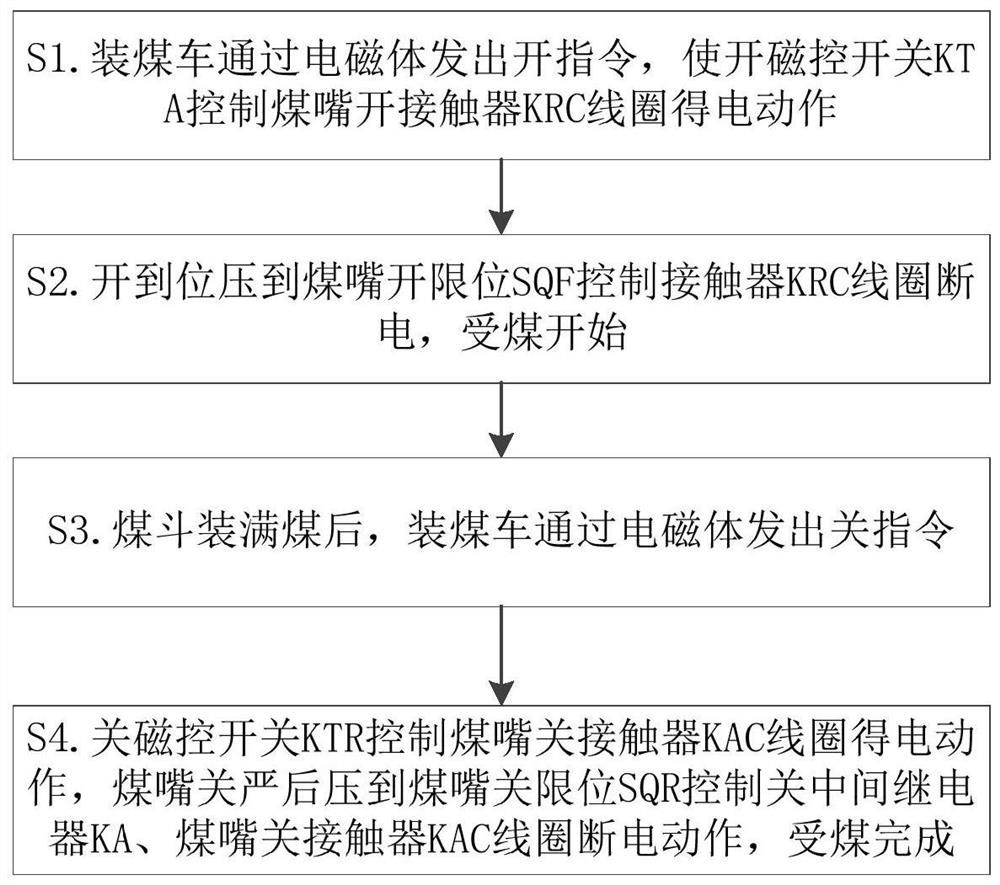

[0051] Such as figure 2 As shown, a coke oven coal tower coal nozzle control method includes:

[0052] S1. The coal loading car sends out an open command through the electromagnet, so that the open magnetic control switch KTA controls the coil of the coal nozzle open contactor KRC to energize;

[0053] S2. Open to the position and press to the coal nozzle open limit SQF control contactor KRC coil power off, start receiving coal;

[0054] S3. After the coal hopper is filled with coal, the coal loading truck sends a closing command through the electromagnet;

[0055] S4. Close the magnetic control switch KTR to control the coil of the coal nozzle to close the contactor KAC to get electricity. After the coal nozzle is closed tightly, press it to the limit position of the coal nozzle. SQR controls the closing of the intermediate relay KA and the coal nozzle to close the contactor. Coal is done.

[0056] During specific implementation, the described coal receiving process also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com