In-situ cold-recycling construction process and quality control platform for cement-stabilized base layer

A technology of cement stabilization and construction technology, applied in roads, road repairs, roads, etc., can solve problems such as poor structure and affecting crushing efficiency, achieve intermittent uniform feeding, and improve extrusion crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

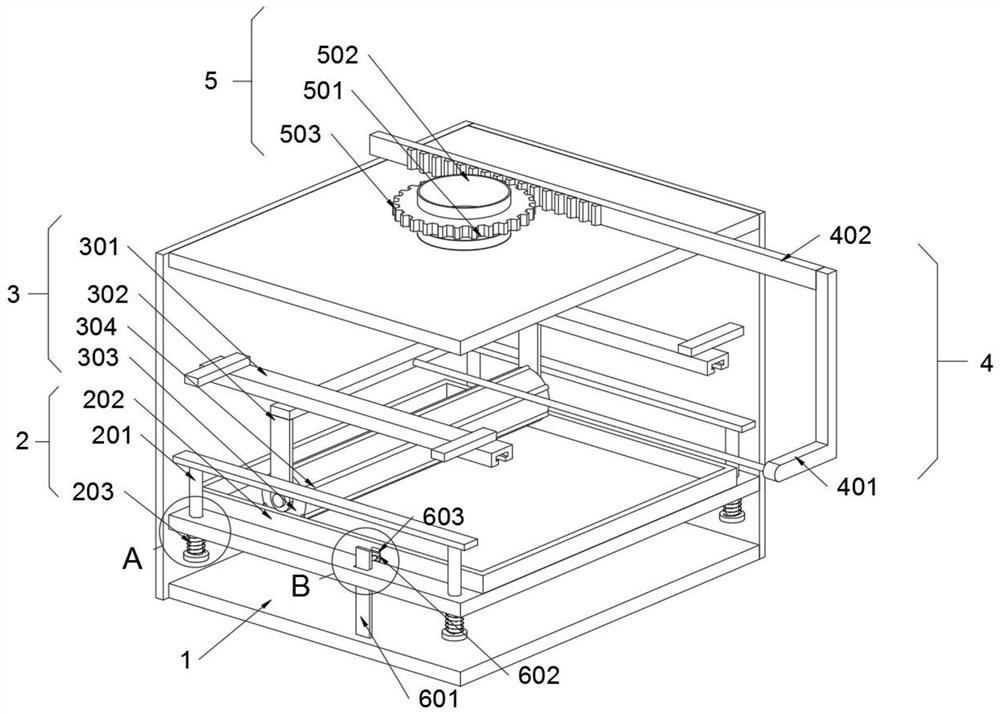

[0026] as attached figure 1 to attach Figure 4 Shown:

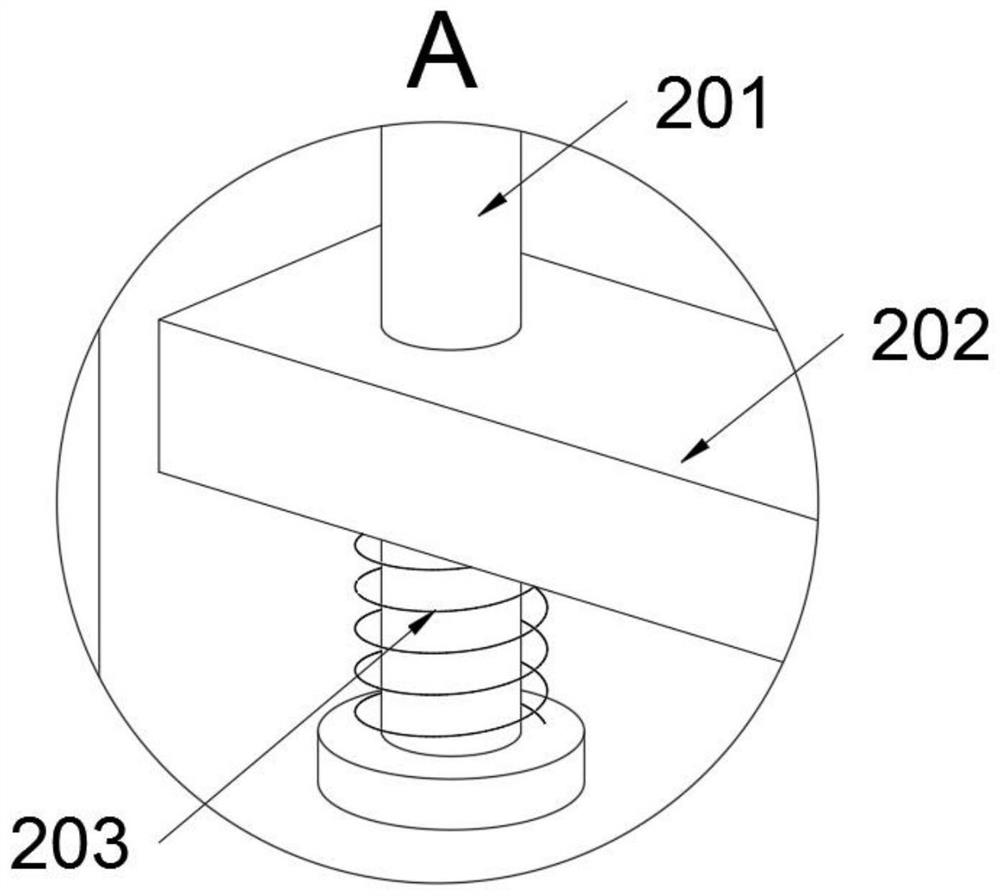

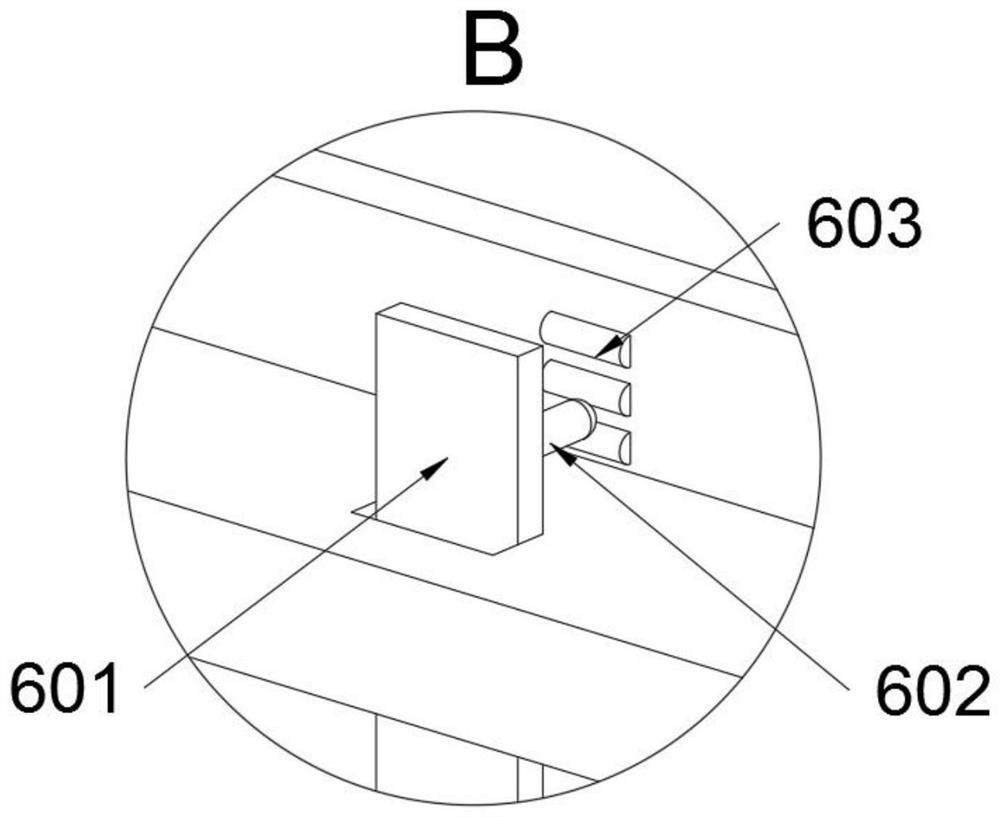

[0027] The invention provides a construction process and a quality control platform for in-situ cold regeneration of cement stabilized bases, including a box body 1; a placement structure 2 is installed in the box body 1, and an extrusion structure 3 is also installed in the box body 1, and the extrusion structure 3 A driving structure 4 is welded on the top; a feeding structure 5 is installed on the box body 1, and an auxiliary structure 6 is also installed on the box body 1; refer to as figure 1 and image 3 , the auxiliary structure 6 includes a mount 601, a toggle lever 602 and a protrusion B603, the mount 601 is welded on the bottom end surface of the inner wall of the box body 1, and the toggle lever 602 is welded on the mount 601, and the head of the toggle lever 602 The end is a hemispherical structure; the protrusions B603 are welded on the placement base 202 in a rectangular array, and the protrusions B603 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com