A printing ink cartridge processing machine

A printing ink and machine technology, which is applied in the field of printing ink cartridge processing machines, can solve the problems of different sizes of ink cartridges, heavy machine force, cumbersome operation, etc., and achieve the effects of improving extrusion crushing efficiency, improving pressing effect, and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

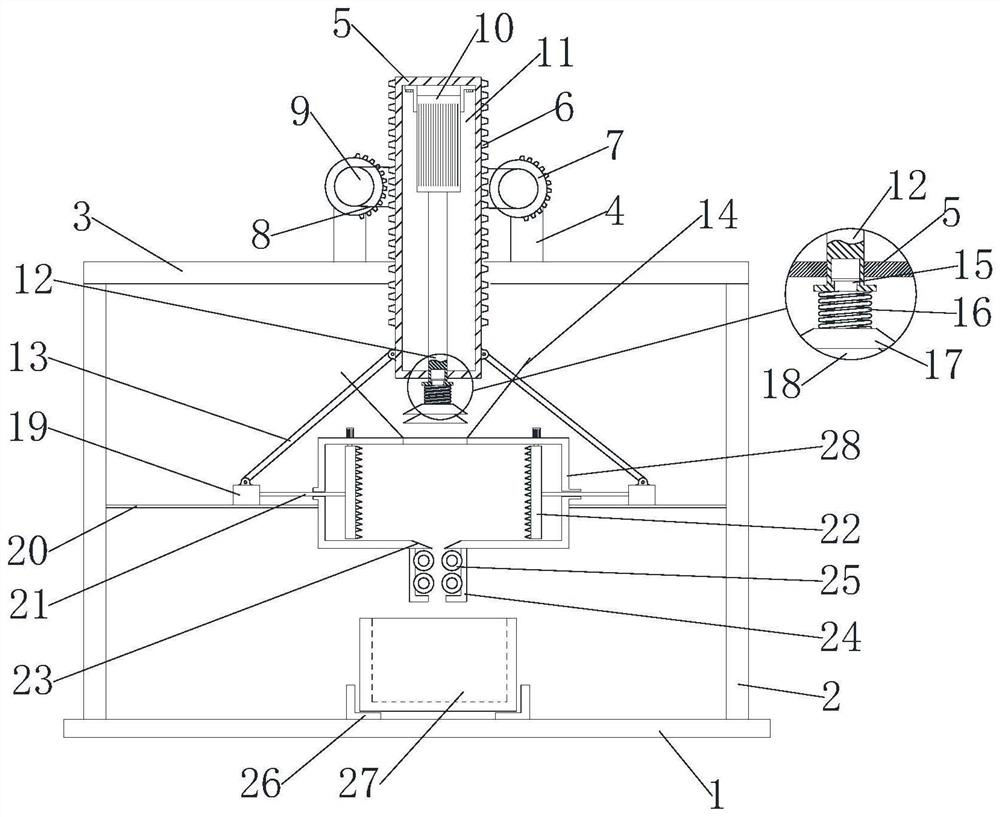

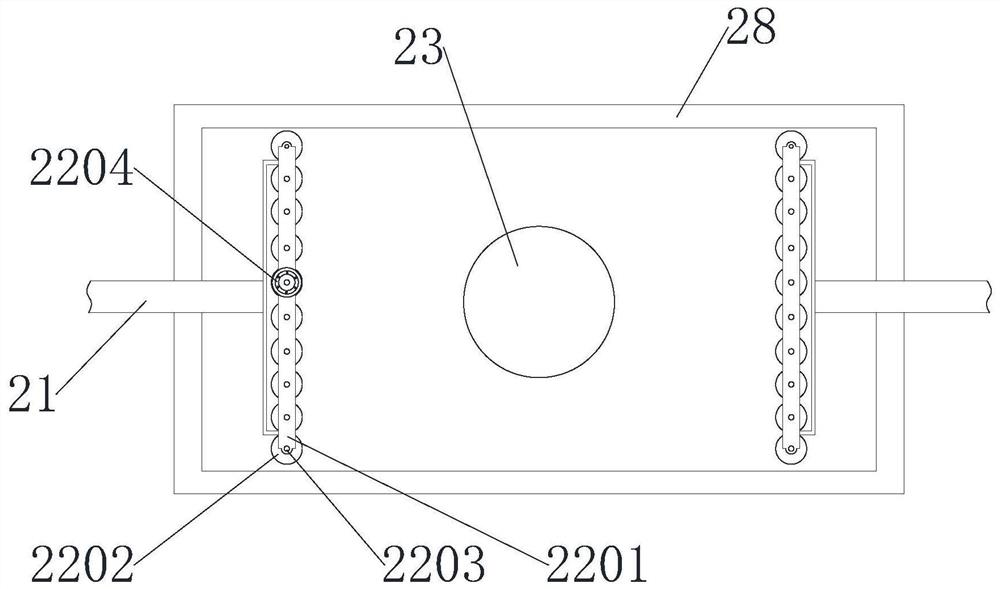

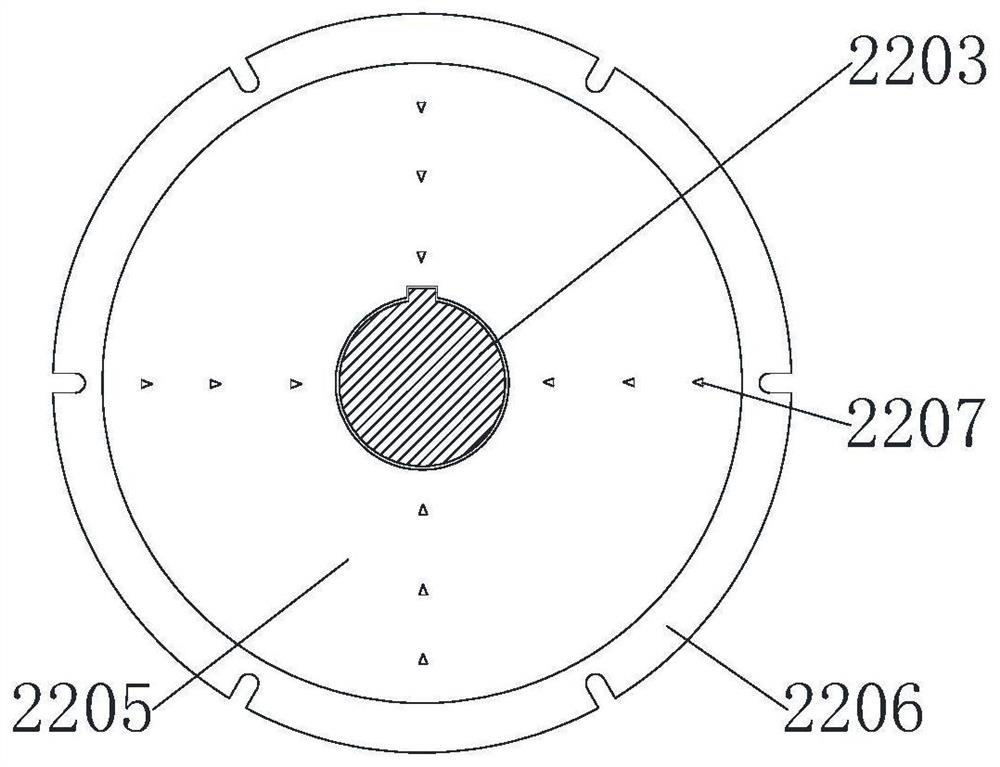

[0035] see Figure 1-6 , a printing ink cartridge processing machine, including a base 1, the base 1 is a square plate structure fixed horizontally on the ground, the top of the base 1 is symmetrically fixed on the left and right sides, and the supporting ribs 2 upright on the top of the base 1 are fixed, and the supporting ribs 2 are square prisms The top of the symmetrical support ribs 2 on both sides is connected with a horizontally fixed beam frame 3, the beam frame 3 is a square plate structure, and the middle part of the top of the beam frame 3 is provided with a through slide hole, the slide hole is a square hole, and the beam frame The sliding hole of 3 is installed with a lifting column 5 through sliding fit, and the lifting column 5 is installed upright above the base 1. The left and right side walls of the lifting column 5 are symmetrically provided with racks 6, and the sliding holes of the beam frame 3 are symmetrical on both sides. A raised support base 4 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com