Construction waste disposer

A technology of garbage disposal and body, applied in grain processing, construction waste recycling, transportation and packaging, etc., can solve problems such as soil and groundwater pollution, environmental pollution, etc., achieve the effect of improving efficiency and realizing automatic crushing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

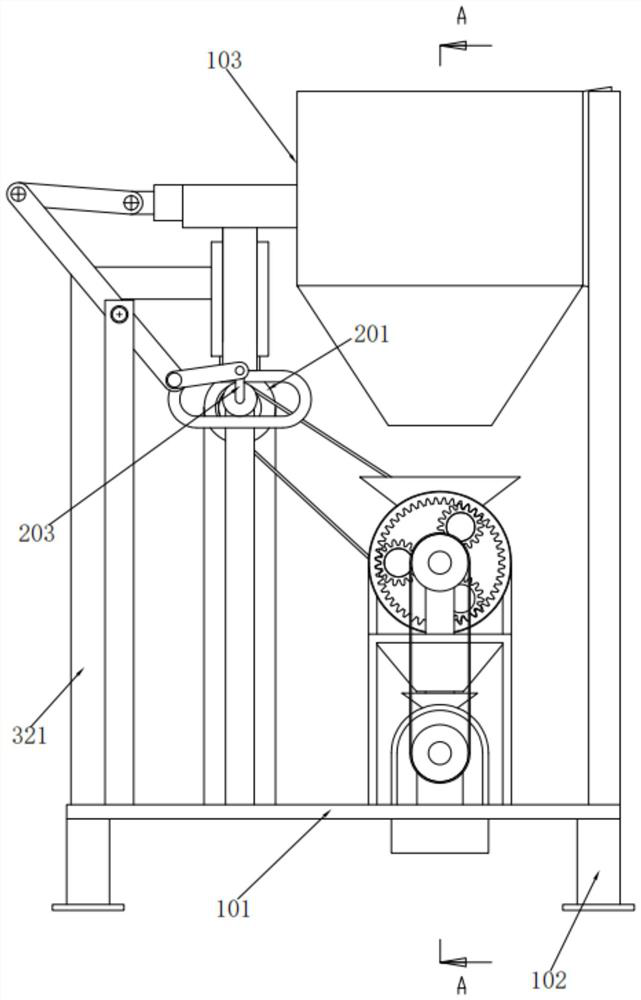

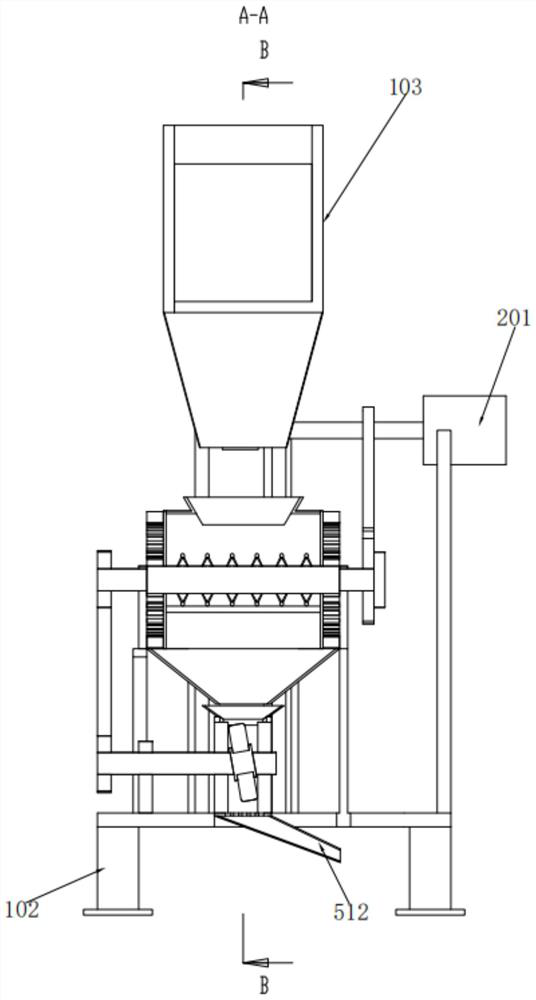

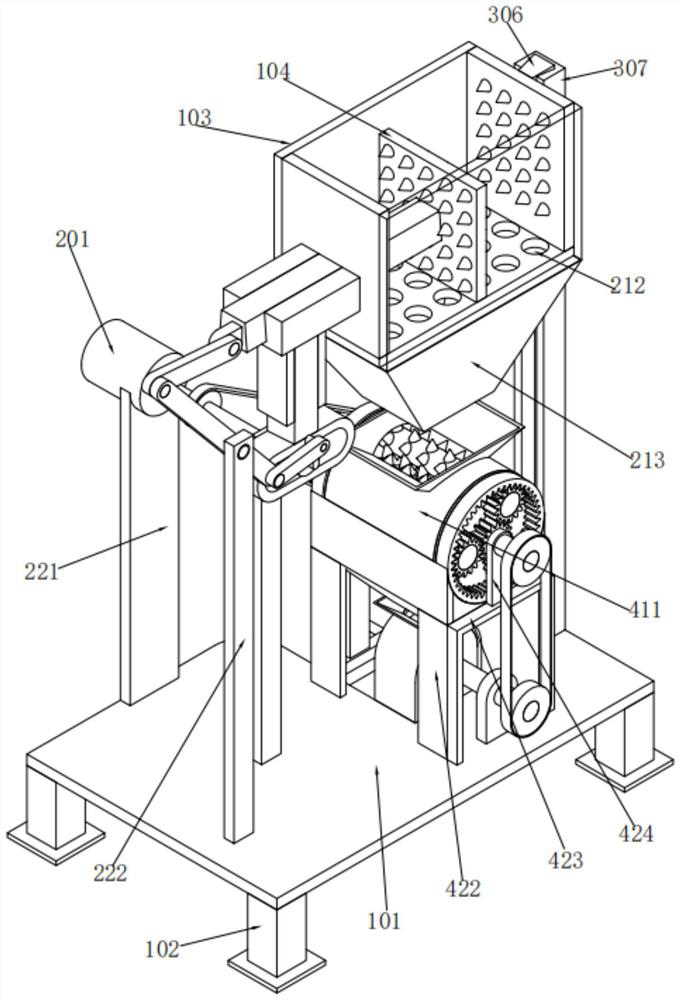

[0031] like Figure 1-11 shown, refer to figure 1 and image 3 , a construction waste disposal machine comprising

[0032] Body 101, the bottom of which is fixed with outriggers 102;

[0033] Breaking box 103, which is connected with body 101;

[0034] Extrusion plate 104, which is configured in the processing box 103;

[0035] The squeeze crushing mechanism 200 drives the crank-link slider mechanism through the motor 201 to make the squeeze plate 104 reciprocate left and right, so as to squeeze and crush the construction waste in the crushing box 103 .

[0036] The present invention can drive the extrusion crushing mechanism 200 through the motor 201, so that the extrusion plate 104 reciprocates left and right, and the left and right sides of the extrusion plate 104 are used to extrude the construction waste entering the crushing box 103, so as to realize the crushing of construction waste. Automatic crushing process improves the efficiency of extrusion crushing.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com