Construction engineering foundation pit supporting steel formwork

A technology for foundation pit support and construction engineering, applied in construction, infrastructure engineering, excavation, etc., can solve problems such as heavy workload, inconvenient assembly and disassembly, and cumbersome construction process, reducing storage space and suitable for many occasions. , the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

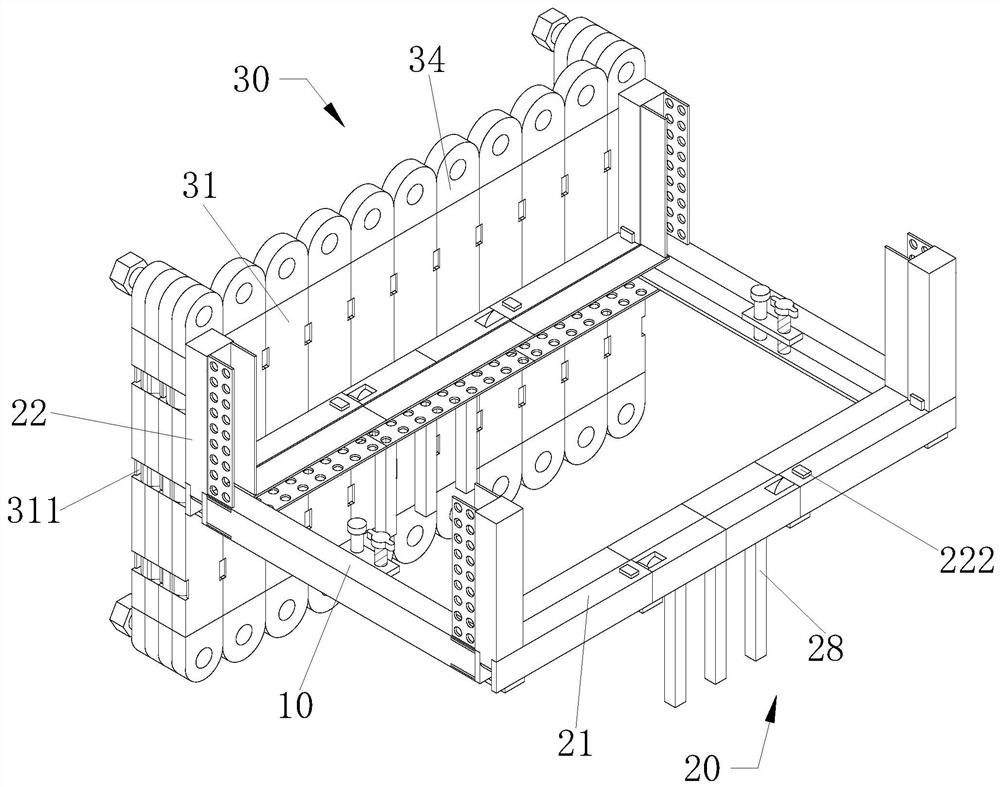

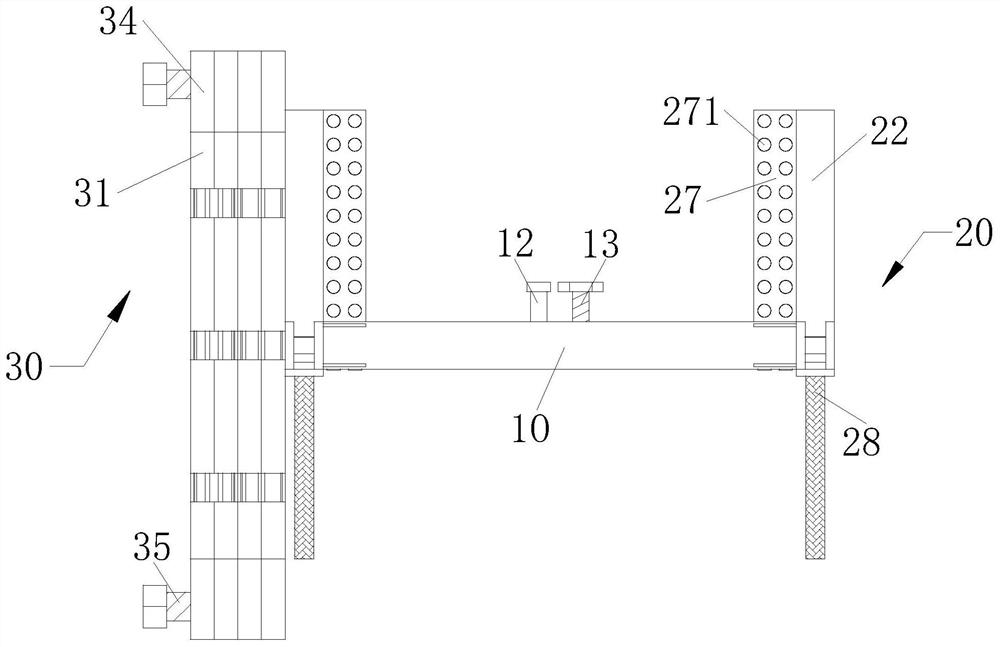

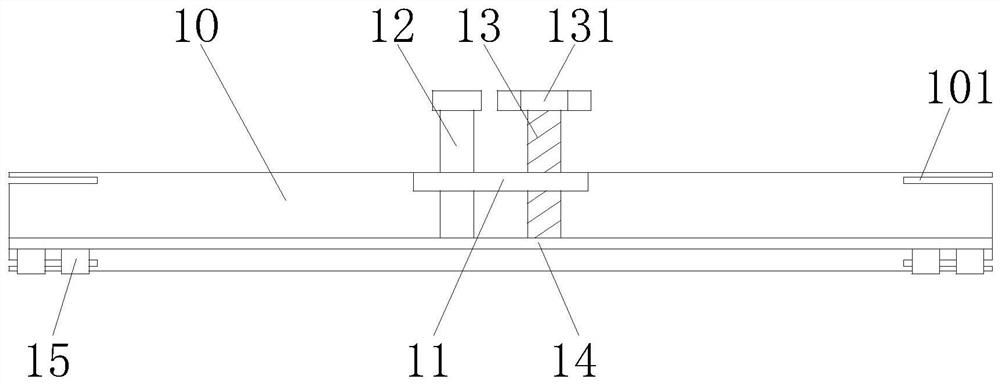

[0031] Such as Figure 1 to 9As shown, a building engineering foundation pit support steel template includes a rectangular steel frame 10 provided before and after, and the left and right ends of the rectangular steel frame 10 are symmetrically opened, the end surface of the moving groove 101 is rectangular, the mobile groove 101 extends in the longitudinal direction of the rectangular steel frame 10, and the moving groove 101 is symmetrically opened, and the width of the moving groove 101 is equal to the width of the rectangular steel frame 10, the side wall center between the two sets of rectangular steel frames A side stretch plate 11 is provided, and the top of the side extension plate 11 is rotated to the left end of the side extension plate 11, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com