Underground mine raise boring machine

A technology for raise drilling rigs and mines, which is applied in earthwork drilling, drilling equipment, support devices, etc., which can solve problems such as inconvenient movement, achieve the effects of reducing labor costs, lightening the burden of transportation, and meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

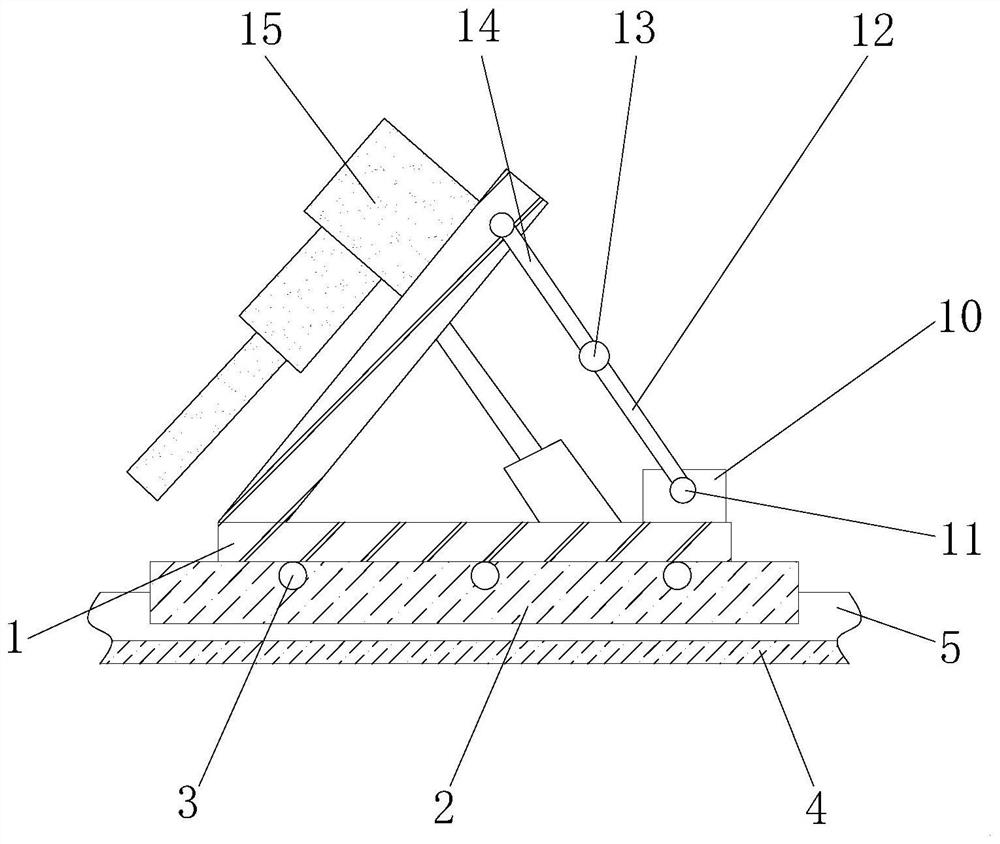

[0030] see Figure 1-3 , an underground mine raise drilling machine, comprising a base 1, the front of the base 1 is movably connected with a slider 2, the front of the slider 2 is provided with a fixing groove 3, the number of the fixing groove 3 is three, and the three fixing grooves 3 Equidistantly arranged on the front of the slider 2, the outer wall of the slider 2 is movably connected with a fixed plate 4, and the front of the fixed plate 4 is provided with a chute 5, and the shape and size of the slider 2 and the shape and size of the chute 5 are matched with each other. And the base 1 is movably connected with the chute 5 through the slider 2, the inner wall of the fixed groove 3 is movably connected with a bolt 6, the shape and size of the bolt 6 and the shape and size of the fixed groove 3 are all matched with each other, and the bolt 6 is connected with the sliding groove through the fixed groove 3. The block 2 is movably connected, and through the set fixing groove...

Embodiment 2

[0036] During the drilling operation, the broken cuttings are washed by the flushing fluid when the pilot hole is drilled, and the cuttings are lifted out of the borehole by the flushing fluid along the annular space between the drill pipe and the hole wall. The friction between the flushing fluid and the drill pipe can easily lead to poor slag discharge, and easily cause disturbance to the drill pipe, affecting the accuracy of drilling.

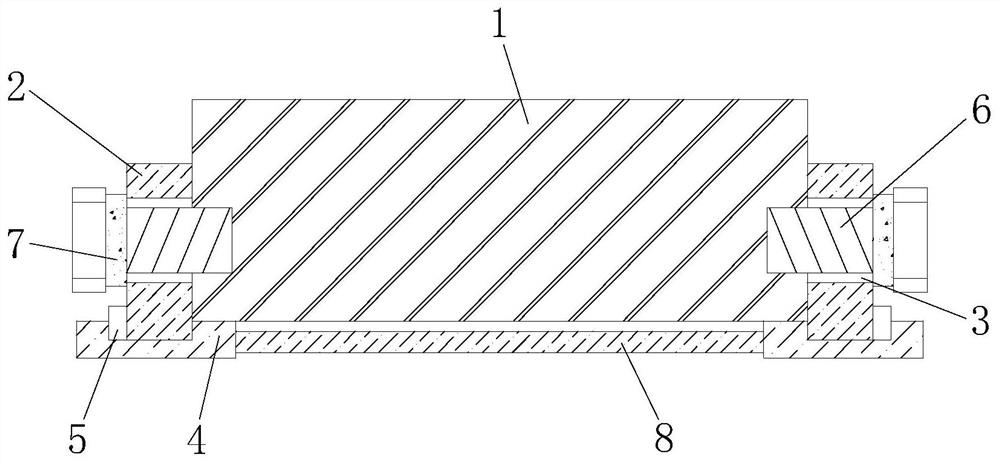

[0037] In order to solve the above-mentioned problems, the raise drilling machine provided by this embodiment also includes a friction-reducing drill pipe, refer to Figure 4 , the friction-reducing drill pipe includes: a rod body 110 , the inside of the rod body 110 is provided with a well-washing fluid flow path 111 arranged axially along the rod body 110 , and the outer surface of the rod body 110 is provided with a drag-reducing structure.

[0038] When working, the flushing fluid is output from the lower end of the rod body 110 through ...

Embodiment 3

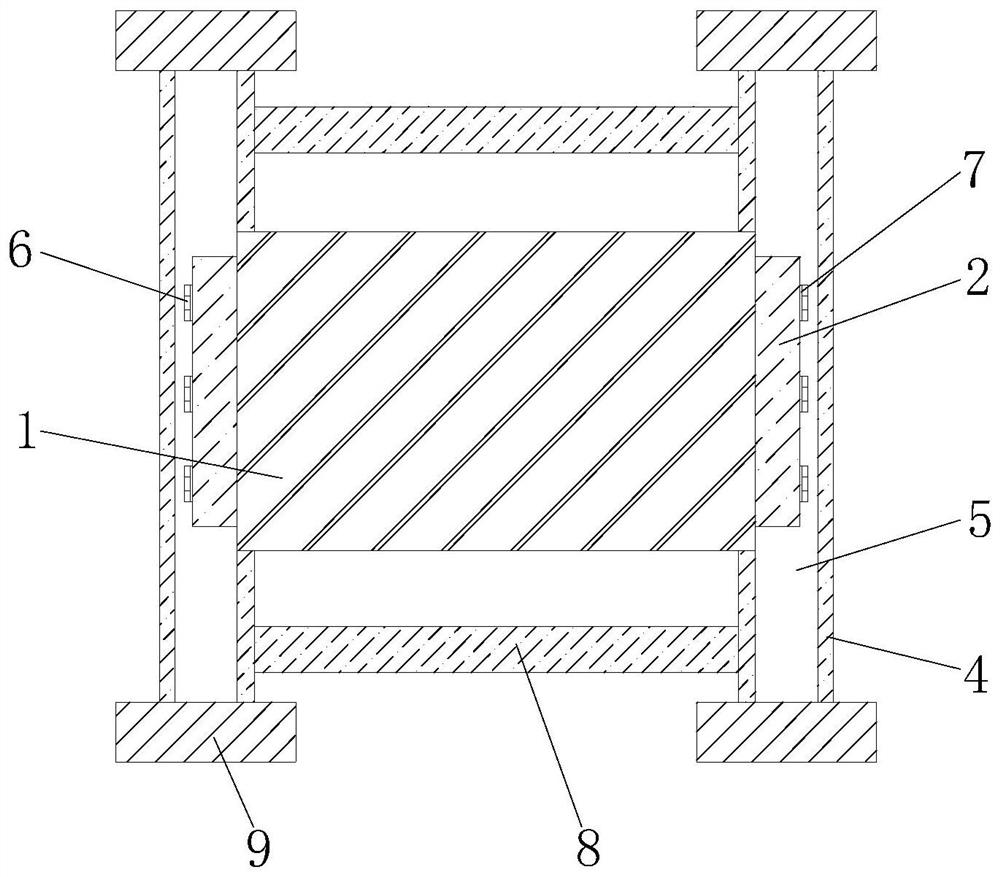

[0051] refer to Figure 8 , On the basis of Embodiment 2, the friction-reducing drill pipe in this embodiment further includes a stabilizing ring 130 , the stabilizing ring 130 is sleeved on the rod body 110 , and the outer diameter of the stabilizing ring 130 is larger than the outer diameter of the rod body 110 .

[0052] When the flushing fluid flows through the stabilizing ring 130 from bottom to top, the circumferential turbulent flow in the stabilizing ring 130 forms a liquid gasket. When the friction-reducing drill pipe deviates, the turbulent flow on the compressed side of the liquid gasket is close to the hole wall, and the liquid pressure Increase to align the reduced-friction drill pipe.

[0053] Specifically, the lower surface of the stabilizing ring 130 and the connecting portion of the rod body 110 have an excessively circular arc. The resistance of the stabilizing ring 130 to the flushing fluid is reduced through the arc transition.

[0054] More specifically,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com