Haze pollutant removal system

A pollutant and smog technology, applied in the field of smog and haze, can solve the problems of large space occupation, easy friction damage, inconvenient movement, etc., to achieve the effect of convenient installation and disassembly, prevention of friction damage, and prevention of inconvenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

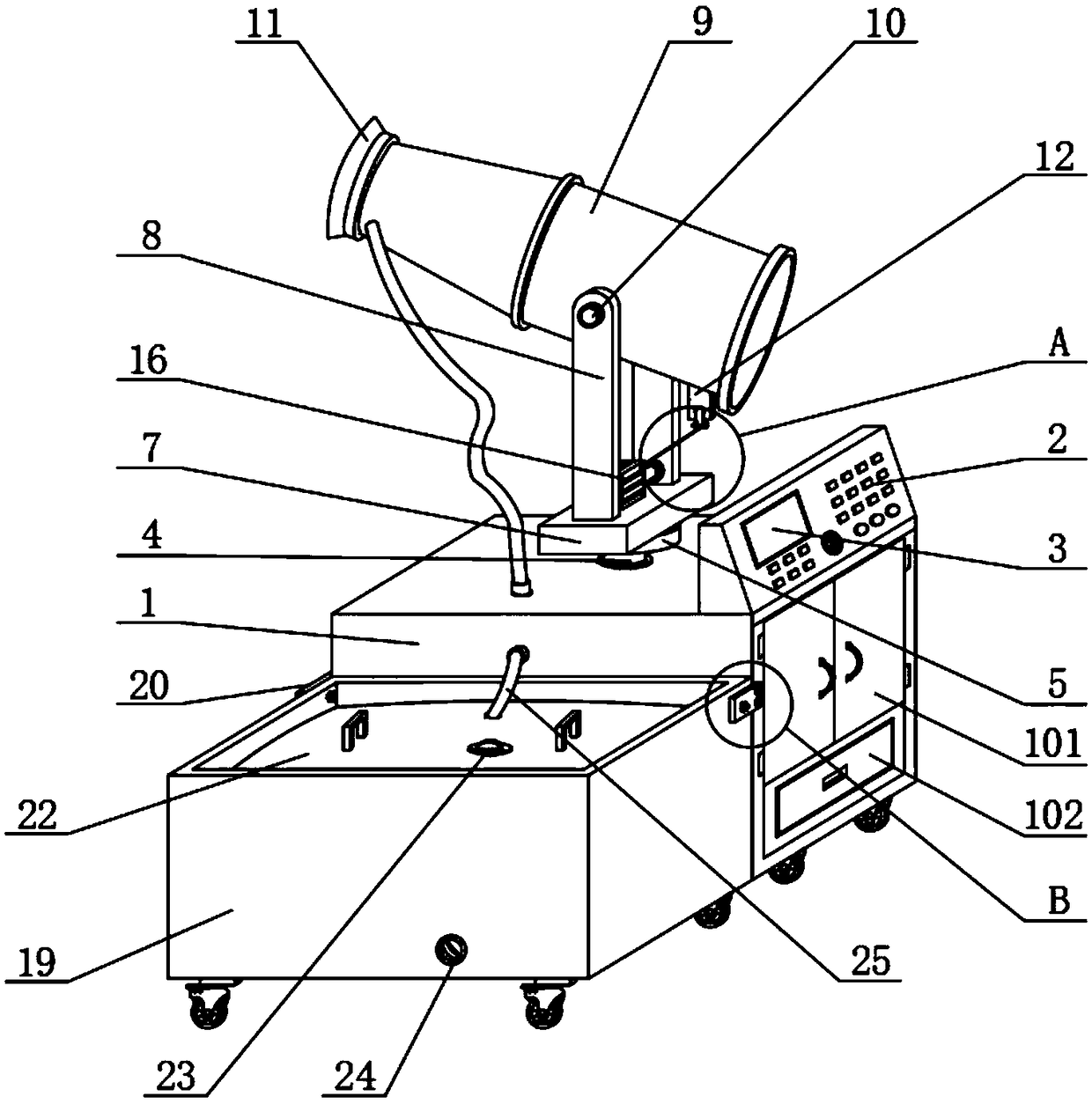

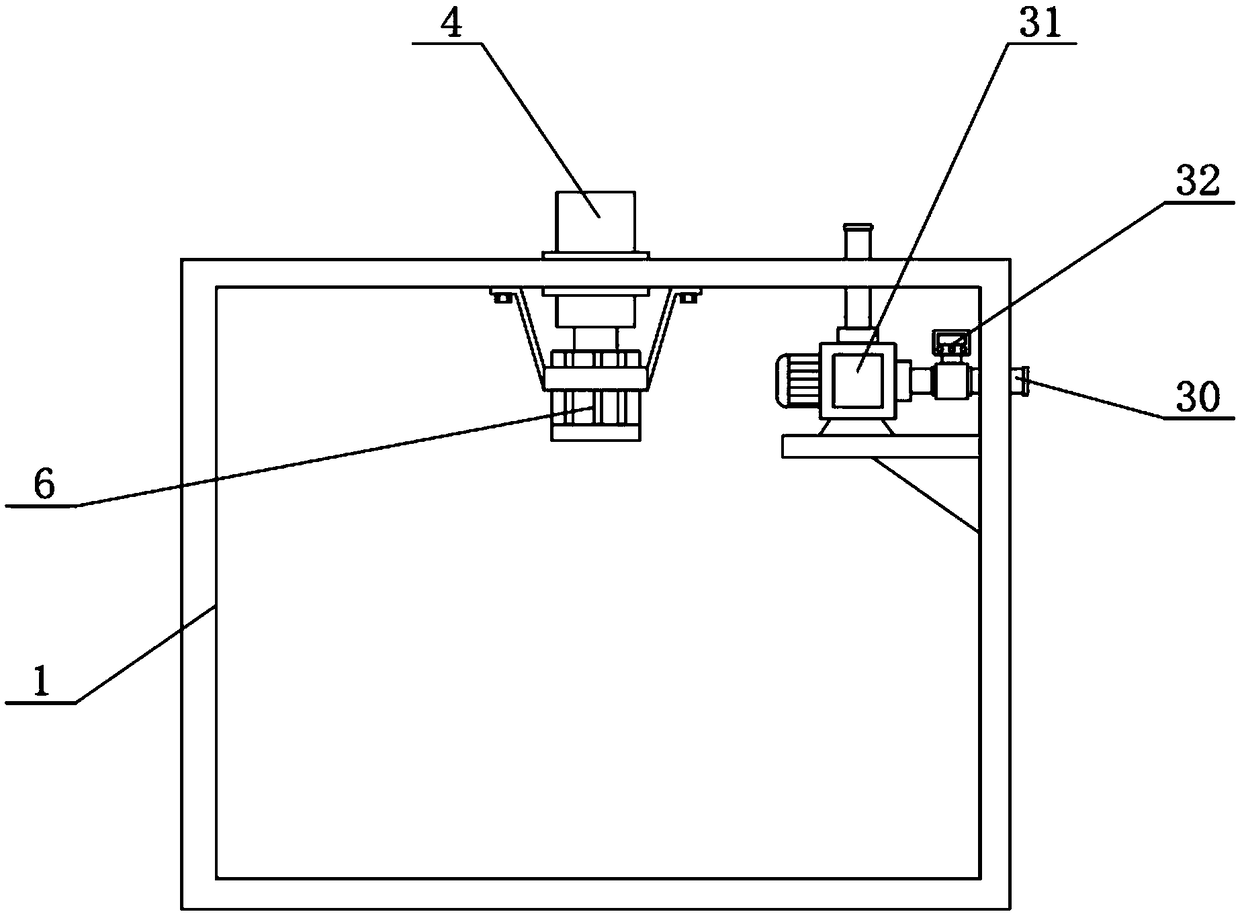

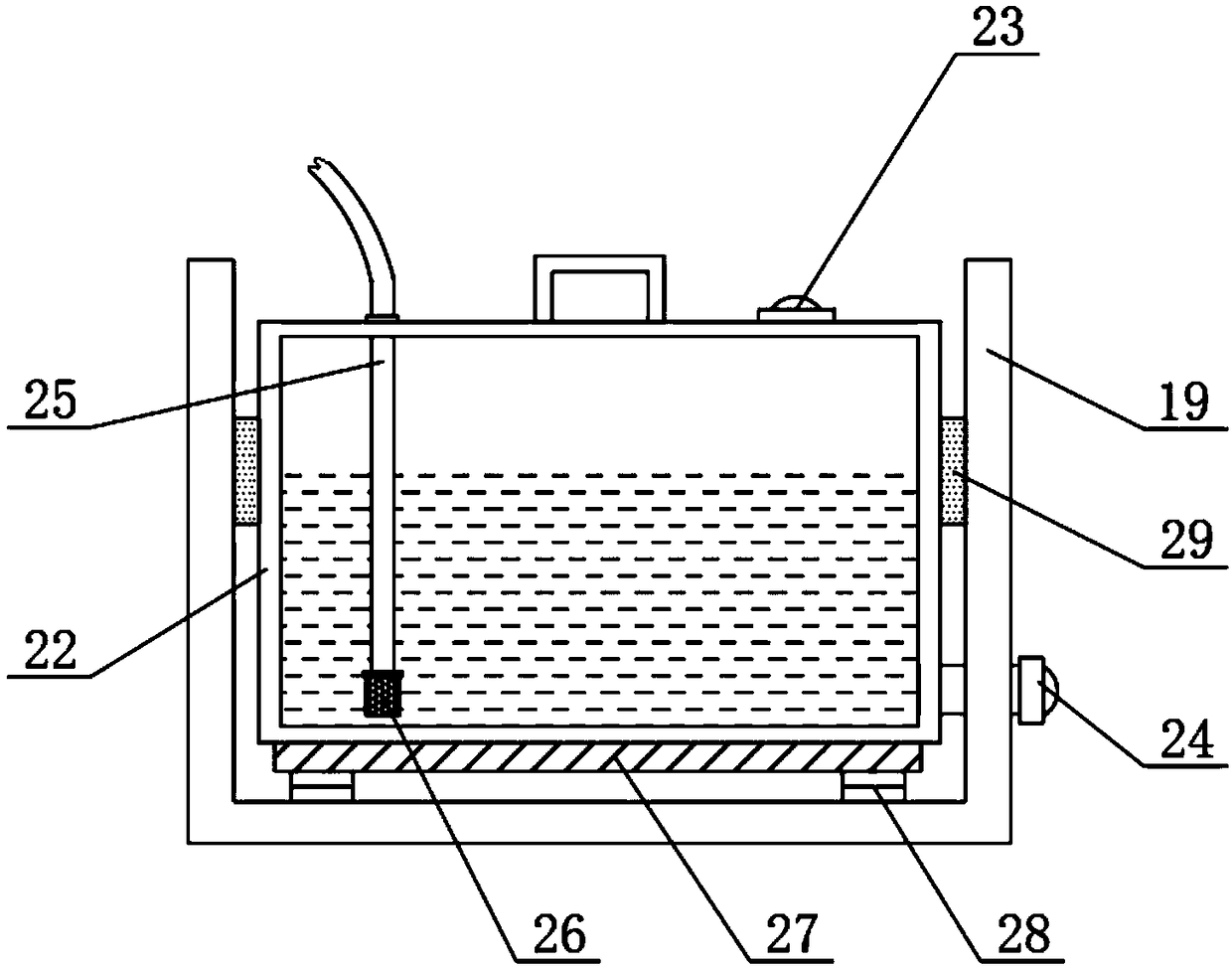

[0028] see Figure 1 to Figure 7, in an embodiment of the present invention, a haze pollutant removal system includes a fixed base 1, an operating console 2 is arranged on the top of the fixed base 1, a display screen 3 is arranged on the operating console 2, and a The center is provided with a rotating shaft 4, the top of the rotating shaft 4 is connected to the turntable 5, the bottom of the rotating shaft 4 is connected to the inside of the fixed seat 1, and the first servo motor 6 is connected, and the top of the turntable 5 is connected to a support plate 7, Above the support plate 7 is provided with a spray barrel 9, and the top of the support plate 7 is located at both sides of the spray barrel 9 and is connected with a support rod 8, and the top of the support rod 8 is connected with a Fixed shaft 10, the top of spray gun barrel 9 is provided with protective cover 11, and spray nozzle 13 is installed at the inboard edge place of protective cover 11, and the inside of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com