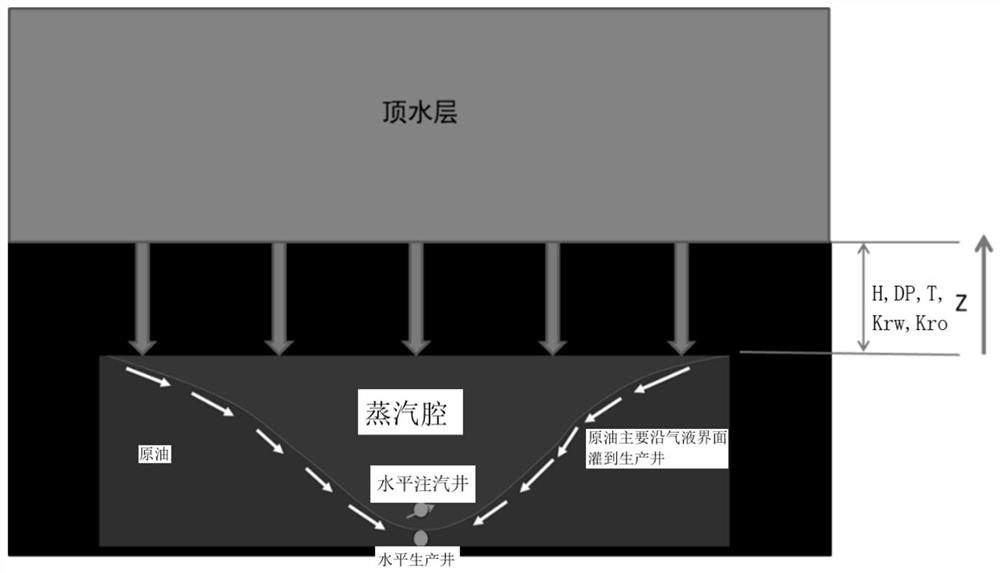

Method for reducing overflow of steam cavity and preventing top water from moving down in SAGD development process

A development process, steam chamber technology, used in the production of fluids, earthmoving, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0117] The present invention provides an example here to optimize the operating pressure of the SAGD steam cavity in a top water reservoir for the Guantao oil layer in a certain block of Liaohe Oilfield, so as to prevent the phenomenon of top water channeling downward due to improper operating pressure of the steam cavity. Specifically include the following processes:

[0118] S100. Determine the current spatial development form of the steam cavity.

[0119] In general, due to the different well layout and production time of SAGD production wells in the reservoir, the development height of the steam chamber of each well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com