Molten metal thermal insulation air-cushion device and thermal insulation using method thereof

A liquid metal and air cushion technology, applied in metal processing equipment, casting equipment, manufacturing tools, etc., can solve the problems of molten metal freezing, aluminum leakage, air leakage, etc., and achieve the effects of reducing waste, saving resources, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

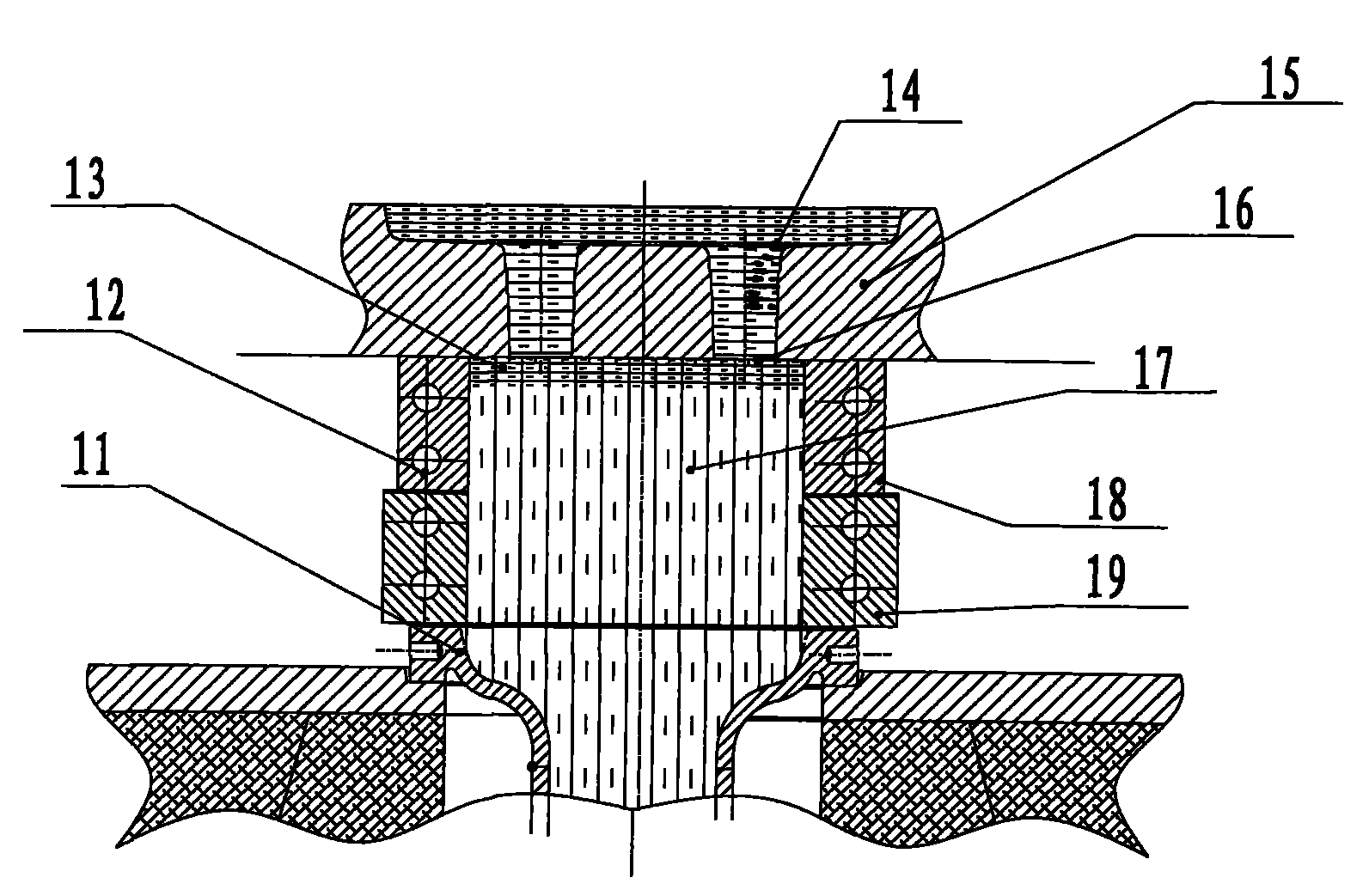

[0011] Such as figure 1 As shown, the known metal liquid heat preservation device comprises a metal square box 19, an electric heating tube 12 is worn in the outer wall of the metal square box 19, and a heat insulating cover 18 is provided on the metal square box 19 to conduct electric heating, so as to realize the metal model The molten metal (that is, the liquid metal 17) between the gate (that is, the upper part of the gate 14 and the lower part of the gate 16) of the bottom of the cavity (that is, the lower mold of the low-pressure casting mold 15) and the nozzle of the molten metal riser 11 is kept warm Features. However, there is a common problem that the molten metal freezes at the ingate at the bottom of the metal mold cavity (that is, there is frozen metal 13).

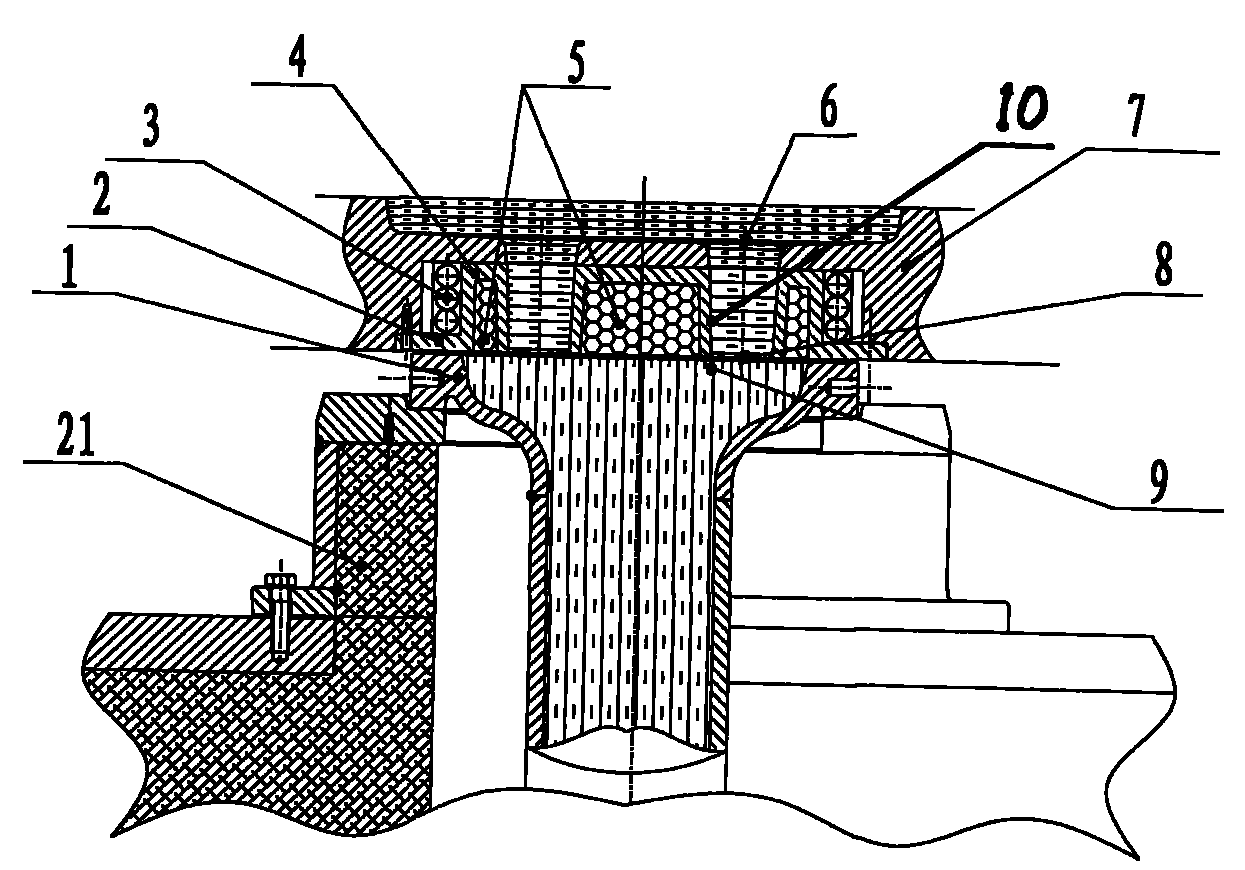

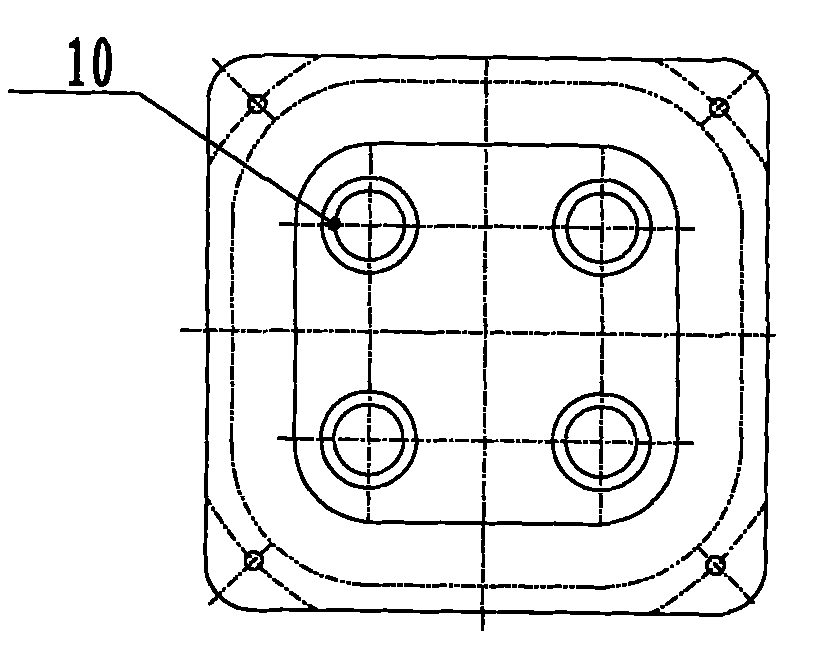

[0012] Such as figure 2 , image 3 As shown, the metal liquid heat preservation air cushion device of the present invention includes an electric heating tube 3, and the heat preservation air cushion devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com