A stabilizing mechanism and stabilizing method of an overturned metal smelting furnace

A smelting furnace, stable technology, applied in the field of stable mechanism, can solve problems such as unstable unloading, molten metal splashing, and potential safety hazards, and achieve the effect of avoiding reciprocating vibration and increasing the support distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

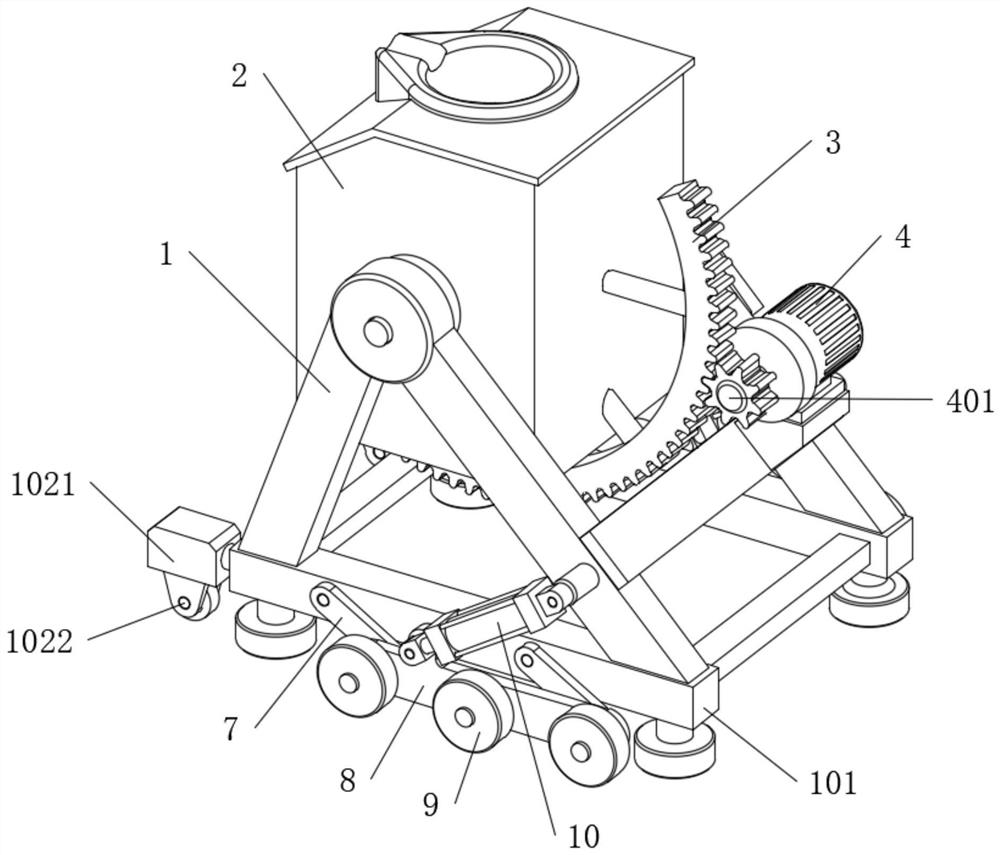

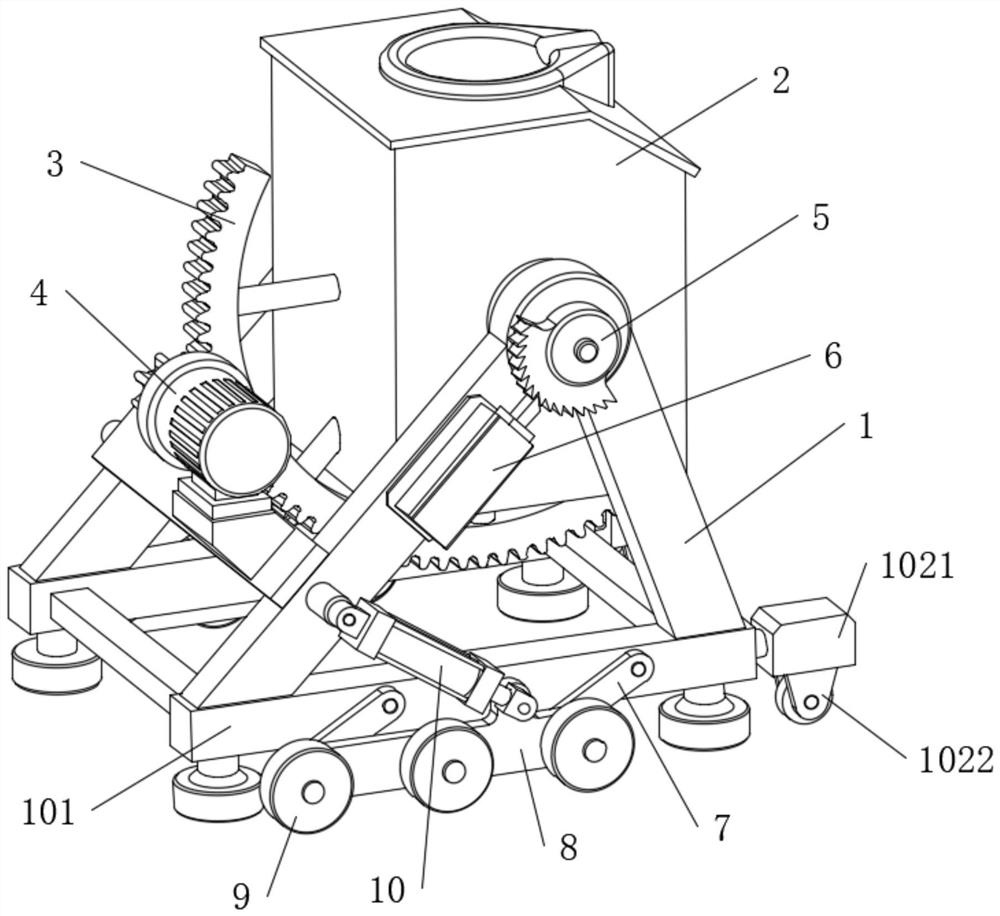

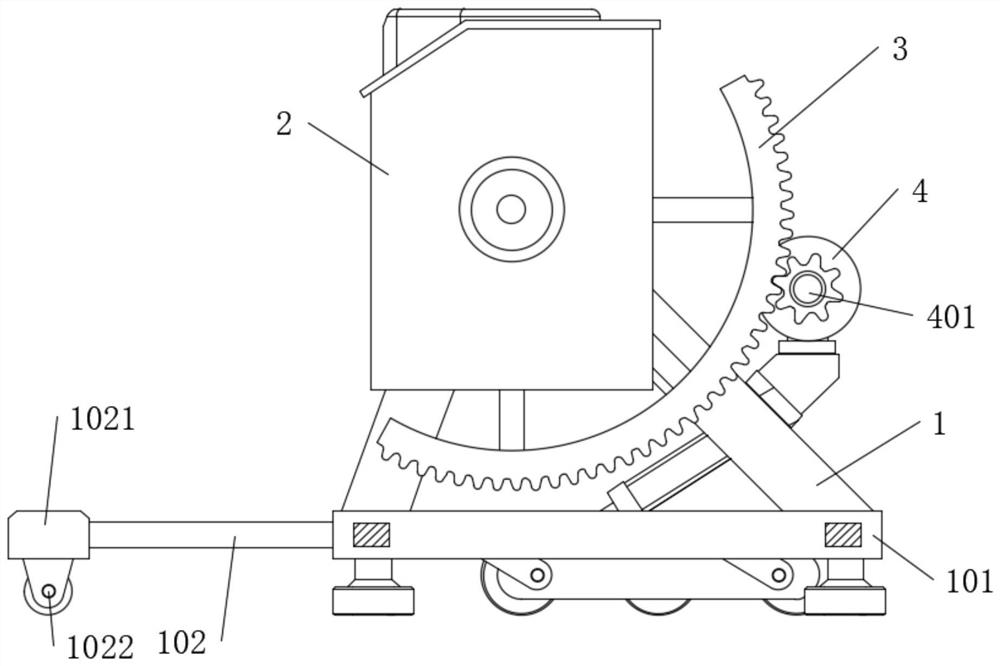

[0028] The present invention provides Figure 1-6 The stabilizing mechanism of a flushing metal smelting furnace is shown, including a smelting furnace bracket 1 and a smelting furnace 2, a smelting furnace bracket 1 consisting of a pair of A-type support, and the sides of the stem 2 pass through the rotating shaft and two type A brackets. The upper end welded, the adapter is transferred, and the bottom pillar 101 is welded to the bottom of the two A-type brackets of the smelt fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com