Braking noise evaluation method combining subjective evaluation and objective test

A subjective evaluation and noise evaluation technology, applied in vehicle testing, machine/structural component testing, measurement of ultrasonic/sonic/infrasonic waves, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

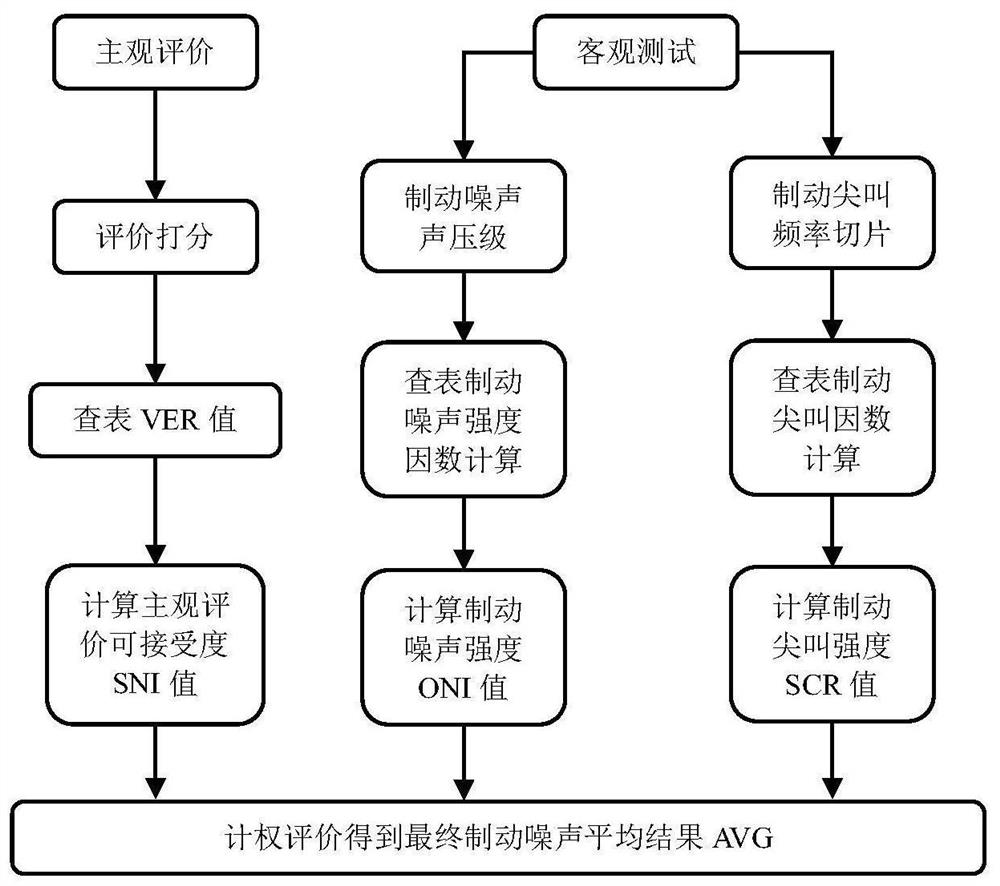

[0030] combine figure 1 , to describe this embodiment in detail. The brake noise evaluation method involving subjective evaluation and objective test involved in this embodiment includes a subjective evaluation process, an objective test process and a weighted evaluation of brake noise.

[0031] The subjective evaluation process includes subjective scoring, determination of VER value and calculation of SNI value.

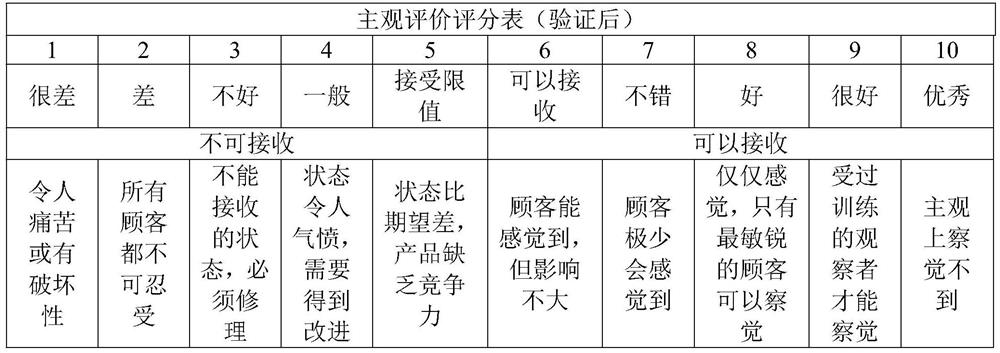

[0032] Subjective scoring refers to the subjective scoring of the vehicle brake noise by testers on a scale of 1-10. The corresponding relationship of the brake noise corresponding to the subjective score is: 1 is very poor, 2 is poor, 3 is not good, 4 is fair, 5 is acceptable limit, 6 is acceptable, 7 points 8 points are good, 9 points are very good, and 10 points are excellent. And in the subjective scoring, 1 to 5 points are unacceptable, and 6-10 points are acceptable. See Table 1 for details:

[0033] Table 1 Scoring criteria for brake noise test

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com